As industries across the U.S. continue to modernize their fabrication processes, industrial-grade wood lathes remain an essential tool in woodworking operations — from furniture manufacturing to precision parts production. In 2025, professionals and procurement teams are turning to e-commerce platforms like Amazon not just for convenience but for real-world user feedback that informs high-stakes purchase decisions. To better understand how these machines perform under commercial and industrial workloads, we conducted a detailed review analysis of Amazon’s top-selling industrial wood lathes. This report distills insights from verified customer experiences, highlighting what operators value most — such as torque consistency, build quality, and serviceability — as well as recurring points of failure or dissatisfaction. Whether you’re selecting equipment for production lines or advising on procurement, this analysis provides data-backed guidance grounded in actual field use.

Table of Contents

Individual Analysis of Top Sellers

WEN Mini Wood Lathe, 8 x 13 Inches with Variable Speed

WEN 3424T – 4.5-Amp 12 x 18 Inch 5-Speed Wood Lathe

Delta IndustrialVariable Speed Midi Lathe

VEVOR Benchtop Wood Lathe

CXRCY Benchtop Wood Lathe

Comprehensive Analysis of Top Sellers

What do customers like the most?

What do customers dislike the most?

Insights for the retailer’s product selection

Conclusion

Individual Analysis of Top Sellers

WEN Mini Wood Lathe, 8 x 13 Inches with Variable Speed

Introduction to the item

The WEN LA3421 is a compact variable-speed wood lathe designed to handle small to mid-sized turning tasks. While it may not fall strictly into the heavy-duty industrial class, it has found widespread use among professional shops needing an auxiliary lathe for light operations or secondary stations. With its 3.2-amp motor, adjustable speed range, and relatively quiet performance, this model appeals to businesses that value affordability without sacrificing essential functionality.

Overall analysis of the comments

With an average rating of 4.3 out of 5 stars, the WEN LA3421 has earned consistently positive feedback from users. Customers frequently mentioned that it performs reliably for its size class, particularly in producing small bowls, pens, or prototype parts. However, many reviews emphasize that it is not intended for continuous industrial workloads, a distinction critical for buyers sourcing machinery for high-throughput operations. Positive ratings were often linked to its ease of use, reasonable pricing, and straightforward setup.

What aspects of this product do users like the most?

Users praised the lathe for its intuitive controls, quiet operation, and value for money. Several reviewers specifically pointed out the lathe’s ability to help new operators or apprentices learn turning techniques safely. Additionally, the WEN customer service team received frequent commendations, especially when users encountered shipping damage or requested part replacements. The machine’s compact footprint also made it ideal for workshops with space constraints or for mobile job-site workbenches.

What flaws did users point out?

Despite the generally favorable impressions, many customers highlighted its limited torque under heavier loads. Several users reported the motor bogging down when cutting more aggressive profiles or working with harder wood species. Others noted that while the speed adjustability was useful, the lathe’s baseline power output made it unsuitable for large or industrial-scale turning tasks. Thus, while well-reviewed, this lathe is best suited for light-duty use rather than intensive production work.

WEN 3424T – 4.5-Amp 12 x 18 Inch 5-Speed Wood Lathe

Introduction to the item

The WEN 3424T wood lathe steps into a more capable tier compared to its compact counterpart, offering a 4.5-amp motor, five-speed operation, and a turning capacity of 12 x 18 inches. Designed with production-grade features in mind, it caters to small-scale industrial users and professional woodworkers who require reliable performance for repeated tasks. Its cast-iron frame adds structural integrity, while the multiple speed settings allow adaptability across materials and workpieces.

Overall analysis of the comments

This lathe has garnered an average rating of 4.6 out of 5, making it one of the highest-rated models in its category. Reviewers consistently applauded its balance of power and precision, especially for jobs involving medium-diameter blanks. Many industrial users regarded it as a strong entry-level option for shop floor integration, particularly in facilities focused on custom runs or detailed craftsmanship. Its versatility across different turning applications was a standout attribute.

What aspects of this product do users like the most?

Among the top features cited were the lathe’s mechanical simplicity, strong torque output for its class, and rigid construction. Users appreciated the spindle lock and tailstock adjustability, which simplified work holding and alignment. A recurring compliment was its smooth operation and minimal vibration, even at higher RPMs. For many, it was considered a dependable secondary unit in a production setting, ideal for shaping handles, spindles, and cylindrical parts.

What flaws did users point out?

Some criticisms were directed at the advertised 12-inch swing, which users discovered did not correspond to the effective usable space due to tool rest and tailstock positioning. A few reviews also reported early wear on belts and minor alignment issues, though these were typically resolved with basic adjustments or replacements. Overall, however, these complaints were outweighed by the machine’s steady performance and solid construction.

Delta IndustrialVariable Speed Midi Lathe

Introduction to the item

The Delta Industrial 46-460 is often positioned as a benchmark in the mid-range industrial lathe segment. With a 1-horsepower motor, electronic variable speed ranging from 250 to 4,000 RPM, and forward/reverse capabilities, it has been widely adopted by small manufacturers, furniture shops, and high-end woodworking studios. Its cast-iron construction and tool-free belt tensioning system make it attractive for professionals who prioritize both precision and production efficiency.

Overall analysis of the comments

Rated at 4.2 out of 5 across over 300 reviews, this lathe received generally strong endorsement for its performance and capabilities, though not without caveats. Users who had experience with commercial or industrial applications praised its stability, speed control accuracy, and finish quality on turned components. However, as many reviews emphasized, the post-sale experience with Delta significantly impacted the overall sentiment. Even highly satisfied users noted that product reliability was somewhat diminished by logistical and service issues.

What aspects of this product do users like the most?

The most frequently cited strengths included its powerful motor, smooth variable speed adjustment, and low vibration at high speeds. Operators appreciated the ease of reversing spindle direction for sanding and finishing, a feature not always available in this price bracket. Several customers also noted that the machine performed exceptionally well on hardwoods and dense stock, making it suitable for both decorative and structural turning work in professional settings.

What flaws did users point out?

Despite its industrial-grade appeal, the most damaging criticism stemmed from Delta’s after-sales support. Users reported extensive delays in obtaining replacement parts, poor response times, and ongoing difficulties navigating warranty claims. In several cases, otherwise, functional lathes were rendered inoperable due to an inability to source critical components. For buyers in production environments where downtime is costly, this represents a serious limitation that undermines the machine’s technical merits.

VEVOR Benchtop Wood Lathe

Introduction to the item

Positioned as a budget-friendly alternative in the industrial benchtop segment, the VEVOR 14 x 40-inch lathe comes equipped with a 0.5 HP motor and four adjustable speed settings ranging from 885 to 2425 RPM. While it is sized for larger workpieces, its entry-level pricing appeals to cost-conscious operations, small-batch workshops, or those needing a backup unit for occasional use. Its specifications suggest industrial capacity, but performance reviews paint a more nuanced picture.

Overall analysis of the comments

This lathe earned an average customer rating of 3.9 out of 5, indicating a mixed reception. Many buyers entered with modest expectations due to its price point and found the machine sufficient for light work or training purposes. However, the sentiment among more experienced users or those using it in a business setting was more critical. The most consistent complaint was that the motor lacked the torque needed to maintain speed under even moderate pressure, severely limiting its effectiveness for sustained industrial use.

What aspects of this product do users like the most?

Reviewers appreciated the machine’s generous work area and affordable pricing. For basic shaping, sanding, or light-duty work, several users reported acceptable results. The inclusion of chisels and faceplate accessories also added perceived value for entry-level users. For occasional tasks in a low-volume production setting — such as prototyping or non-structural turning — the lathe found niche utility.

What flaws did users point out?

The most prominent issue across reviews was motor weakness. Even light contact with cutting tools or sandpaper frequently caused stalling, rendering the lathe unsuitable for anything beyond the decorative shaping of softwood. Multiple users criticized the misleading impression created by its 14-inch capacity, as the actual power and torque were insufficient to handle large-diameter stock. Additionally, concerns about build quality, such as plastic components and inconsistent fit-and-finish, were noted as significant drawbacks for industrial applications.

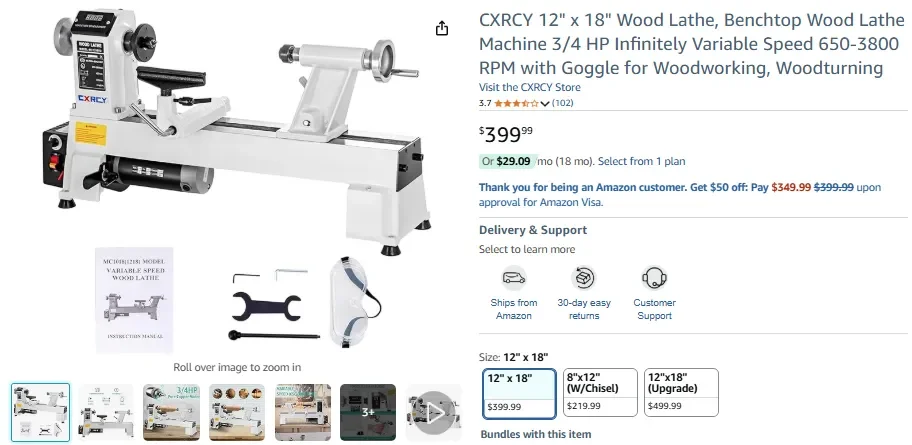

CXRCY Benchtop Wood Lathe

Introduction to the item

The CXRCY 12″ x 18″ benchtop wood lathe targets budget-conscious industrial buyers who need compact, variable-speed machinery for small to medium-turning jobs. With a 3/4 horsepower motor and an infinitely adjustable speed range from 650 to 3800 RPM, it attempts to bridge the gap between entry-level hobbyist tools and light-duty professional equipment. The inclusion of protective eyewear and basic accessories suggests an all-in-one starter solution for teams integrating woodworking into broader production workflows.

Overall analysis of the comments

Customer sentiment around this lathe is notably split, reflected in its average rating of 3.7 out of 5. Some buyers described it as a surprisingly capable machine for the price, capable of handling basic shop work such as handle blanks or small custom components. However, more experienced industrial users voiced concerns about build precision, durability, and technical consistency. These mixed reactions point to a product that may satisfy casual commercial use but falls short in environments that demand repeatable, high-volume output.

What aspects of this product do users like the most?

Reviewers often highlighted the variable speed control as a major advantage, noting that it provided good flexibility when working with different materials. Others appreciated the seller’s responsiveness, particularly when addressing damaged components or setup issues. For light shaping work or initial training, many found the machine adequate — and some even described it as an excellent first lathe for introducing new staff or apprentices to lathe operations.

What flaws did users point out?

The most consistent concerns were about construction quality and part alignment. Several users noted misaligned headstocks and tailstocks out of the box, while others reported that paint chipping and casting flaws were visible even before use. Moreover, reviews flagged that the mounting system required manual modification for stable use, a potential red flag for industrial buyers expecting plug-and-play integration. Weak documentation and minimal user support further undermined the lathe’s fit for rigorous or time-sensitive commercial tasks.

Comprehensive Analysis of Top Sellers

What do customers like the most?

Across all five top-selling wood lathes, certain features consistently stood out as value drivers for industrial users. One of the most appreciated attributes was variable speed control, particularly in models like the Delta 46-460 and the CXRCY lathe. Operators relied on this feature to adapt turning speed to different wood species and part profiles, enhancing precision and safety in the process.

Build quality and stability were also critical factors praised by buyers. Lathes like the WEN 3424T and Delta 46-460 earned strong approval for their heavy cast-iron frames and vibration-resistant operation, which directly supported smoother surface finishes and reduced tool chatter. In industrial environments where repeatability and finish quality are non-negotiable, these machines were seen as reliable contributors to workflow efficiency.

Another noteworthy trend was the positive sentiment toward customer service responsiveness — particularly in the case of WEN and, to some extent, CXRCY. Users who encountered technical issues or shipping damage emphasized that timely support and quick part replacement could offset initial frustrations and maintain uptime on the shop floor.

Lastly, space efficiency and footprint emerged as a decision-making factor. Smaller industrial operations and mobile service providers valued benchtop models that delivered respectable turning capacity without overwhelming limited shop space.

What do customers dislike the most?

The most pervasive point of dissatisfaction was motor underperformance, especially in lathes that advertised higher swing capacities but failed to deliver adequate torque. The VEVOR unit, for instance, was widely criticized for stalling under even light resistance—an issue that rendered it impractical for anything beyond softwood shaping. Industrial buyers interpreted this not just as a flaw in engineering but as a misalignment between marketed capabilities and real-world applications.

After-sales service limitations were another serious concern, particularly with Delta. Despite the 46-460’s mechanical strengths, many users reported prolonged service delays, unavailable parts, and unresponsive support. In commercial settings where downtime translates directly to financial loss, these support deficiencies significantly erode brand trust.

Reviews of the CXRCY and VEVOR lathes also revealed precision issues, such as misaligned tailstocks, loose tool rests, or warped castings. For industrial users working with high-volume or dimensionally sensitive production, these tolerances were unacceptable and often led to returns or workflow disruption.

Lastly, build quality shortcuts such as chipping paint, inconsistent finishes, and fragile components were red flags in models positioned at entry-level price points. These cosmetic and structural issues signaled a lack of durability, raising long-term concerns about the machine life cycle in production environments.

Insights for the retailer’s product selection

For industrial buyers, the wood lathe purchase decision hinges not only on technical specifications but also on operational reliability, maintainability, and precision consistency. The review data highlights that lathe performance under load — particularly torque delivery and spindle stability — must align with stated capacity claims. Retailers curating inventory for industrial customers should prioritize models with reinforced motor assemblies, cast-iron beds, and tight machining tolerances.

Equally important is the after-sales infrastructure. Brands with dependable support networks and readily available replacement parts gain a competitive advantage in the industrial segment, where machine downtime incurs real financial risk. Retailers should consider showcasing warranty terms, service logistics, and parts availability as part of the product presentation to instill buyer confidence.

In terms of design features, variable speed ranges, reversible drive capability, and quick-adjust tailstocks are highly valued for their versatility and safety in fast-paced shop environments. Lastly, while affordability plays a role, cost must not come at the expense of build integrity—budget models that compromise on motor torque or structural precision are unlikely to earn repeat business from professional clients.

Conclusion

The industrial wood lathe market on Amazon in 2025 reflects a clear divergence between models engineered for professional reliability and those constrained by cost-driven compromises.

Our analysis shows that while budget-friendly units may serve entry-level functions, only a select few — such as the Delta 46-460 and WEN 3424T — consistently meet the operational demands of industrial users in terms of power, precision, and durability.

For procurement teams and workshop managers, aligning purchase decisions with verified performance indicators — especially around torque stability, build quality, and post-sale support — is essential to ensuring both productivity and machine longevity on the shop floor.