Is there a difference between screen printing and digital printing? The obvious answer is yes! In fact, these two printing methods are widely used across different industries to deal with small and large orders.

But wouldn’t it be great to find out which printing machine ranks better in each department and is more suitable for a specific industry?

This blog will compare screen printing against digital printing, finding out which comes out on top and is popular among different businesses.

Table of Contents

Screen printing overview

Digital printing overview

What are the factors to consider when comparing both?

Conclusion

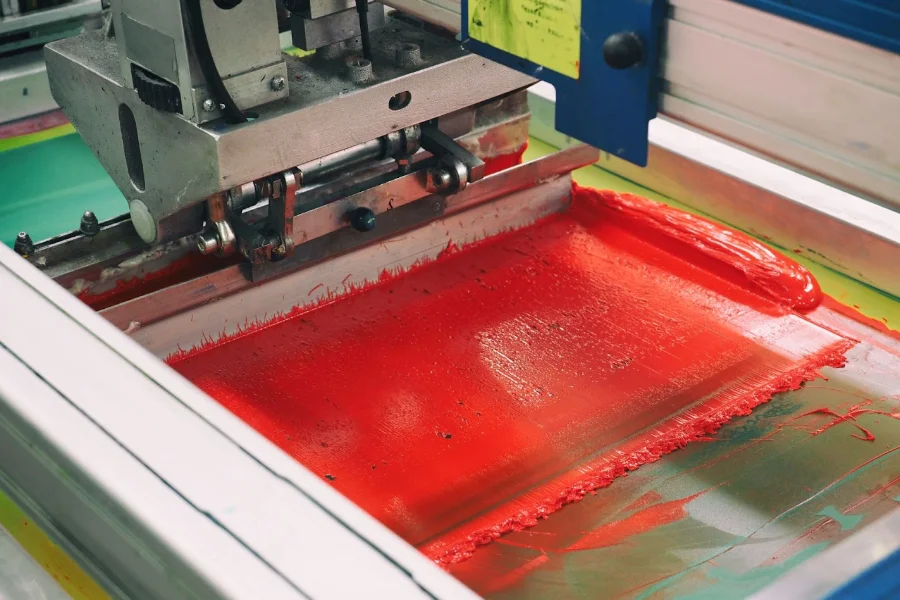

Screen printing overview

Screen printing involves the usage of a stencil(also known as a screen). In the printing process, layers of ink get applied individually to the printing surface. Hence, a different screen or stencil is utilized for different colors.

When it comes to the global screen printing machine market, its market size is projected to reach around USD $1.282 billion by 2028, registering a CAGR of 5.62% between the forecast periods of 2022 and 2028.

Here are some of its pros and cons in detail:

Pros

- It offers versatility, supporting various garments and textiles.

- Screen printing utilizes water-based inks and plastisol inks—which produce vibrant colors.

- It offers high durability with high retainability after several washes.

- Its special inks offer a better printing effect to the texture—making it stand out with a glowing effect.

- It’s considered cost-effective, especially when it comes to printing bulk orders..

Cons

- It’s quite expensive to operate because of the different screens used when printing multiple colors.

- It can hardly run one design per batch.

- Screen printing machines require a large upfront investment.

Digital printing overview

Digital printing, also known as DTG printing (Direct-to-Garment), is more modern and involves the usage of advanced computing. In this printing process, the image on the screen is first analyzed and then converted into a printable format, which is applied to the printing surface.

The digital printing market size is estimated to reach about USD $34.3 billion by the year 2026, reaching a CAGR of 6.7% between 2021 and 2026.

Here are some of its pros and cons in detail:

Pros

- Digital printing prints emphasize the details of prints, creating high quality output.

- It offers better color blends.

- Digital printing provides more consistency to its prints, thanks to its advanced computing.

- Digital printing is considered to be pretty quick.

- It allows regular modifications to the print if required.

Cons

- Since the ink isn’t fully absorbed into the printing paper, it tends to create cracks in the folds.

- It’s quite expensive to use.

- There may be slight cases of different or mismatched print colors.

What are the factors to consider when comparing both?

Here are the following conditions to check:

Set-up time and cost

For screen printing, it’s a bit time-consuming to set up, considering each color requires a separate screen for printing. As a result, it accumulates high costs upfront.

In contrast, digital printing is easier to set up because it uses a computer and has less cost upfront.

Color options

Considering colors, screen printing offers better color options, matching, vibrancy, and special effects to the print.

Contrarily, digital printing utilizes a four-color process. Thus, it falls short when it comes to getting quality color matching. However, it provides better color blending.

Print complexity

Screen printing produces simple image prints as each print is done by applying one color at a time.

However, to produce more complex prints with intricate details, digital printing is the ideal go-to. It produces well-detailed prints for sophisticated images and makes use of digital data to provide consistency.

Print quantity

Screen printing is the best method for printing very large quantities. It has a faster printing speed when dealing with bulk orders. And from the quantity perspective, it can be much more cost-effective.

However, digital printing is cheaper when dealing with smaller quantities, because there is no need to pay an origination fee (one-off setup fee), and has minimal setup cost. But it can be expensive when printing larger quantities due to slow print times and the cost of maintaining the machine for days to produce prints in bulk.

Printing size

Screen printing inks can adhere to printing surfaces such as glass, aluminum, etc. However, they are limited to large printing size capabilities as most screen printing machines have a maximum print size of about 40 x 60 inches.

Whereas, digital inks can adhere to different substances and has a larger print size of about 96 x 48 inches.

Comfort and durability

In terms of comfort and feel, digital printing ranks high. It provides flexibility to the print material.

However, screen printing provides better durability. . Thus, many garments such as t-shirts, pants, skirts, etc., with screen printing won’t fade color after multiple washes in high temperatures.

Conclusion

Which is better; screen printing vs. digital printing? The answer is pretty relative.

Screen printing is more popular as it has been widely used in industries for a very long time but digital printing is slowly making its mark too due to its advanced print features.

So, the answer lies within the several factors these two printing methods were compared with and depends on the industry and applications.

In the end, sellers can make their choice based on the industry, business processes, and specific applications. Luckily, this article has helped lay out all the factors to put into consideration.