While there has been an upsurge in the production and popularity of 3D printers, understanding their key features is essential for sellers. This is why this guide outlines the most important things about 3D printers. Retailers and wholesalers alike will benefit from segments such as global market share and the tips to be considered when choosing

Table of contents

3D printing vs. traditional manufacturing

Global market share of 3D printers

Key tips when choosing a 3D printer

Types of 3D printers

Target market for 3D printers

3D printing vs. traditional manufacturing

3D printing allows for the design and printing of complex models and designs, while traditional printing can print simple designs. In addition, 3D printing uses the material that passes under the laser. On the other hand, traditional printing requires the use of extra materials.

Global market share of 3D printers

As of 2020, the global market share of 3D printers was $13.78 billion. This translates to 2.1 million units of 3D printers shipped in 2020. 3 Dimensional Printing (3DP) is divided into two segments, that is, industrial and desktop. The industrial segment accounted for 76% of the global revenue share. It is expected that (3DP) will further grow in the coming decades. Aggressive R&D and demand for prototype applications in healthcare, defense, and aerospace departments are some of the factors that will fuel this growth.

Key tips when choosing a 3D printer

Based on the needs of each business, the printer choice may vary. Below are vital tips a business should consider before purchasing a 3D printer.

Printing materials

They refer to the materials to be used to make the 3D model. There are quite a few materials available. They include nylon, glass fiber infused, carbon fiber infused, metal fill, wood fill, TPU, TPE, ABS, and ASL. A 3D printer that can use most of these materials will offer better versatility and flexibility. It is good to note that many 3D printers use PLA and ABSs use PLA and ABS.

Resolution

The quality of the models will depend on the resolution that the 3D printer offers. The unit of measuring resolution is in microns. The lower the number of microns, the higher the resolution. For example, a resolution of 10 microns (0.1mm) on the XY axis and 50 microns (0.05mm) on the Z-axis produces an excellent resolution.

What is to be printed

Compatibility between the model to be printed and the material used is essential. The material used to print a model will have to feature the strength and other properties such as flexibility that the model requires. A dental implant will have to be made of a specific material, which dictates the type of 3D printer to acquire.

Quality user interface

The ease of interaction with the 3D printer can be the difference between a good and a great experience. Looking for a printer with a touchscreen UI would be better than one with buttons or a different form of interaction.

Heated bed

Every construction will need its foundation to be strong, firm, and stick in place. Similarly, it is essential for a 3D model that the foundation is strong. A heated bed provides this as it ensures that the first few lines of the model are solid.

Safety features

Safety is important because 3D printers become too hot after use. For example, an automatic cooling nozzle will enhance the safety of the printer while in use. Should the 3D printer have a hotbed, then a feature to close it off after printing is handy.

Print resume functions

This is important when there is an interruption when printing is ongoing. A 3D printer with a print resume will ensure that instead of restarting a print all over and wasting resources, the printer will pick up from where it left.

Types of 3D printers

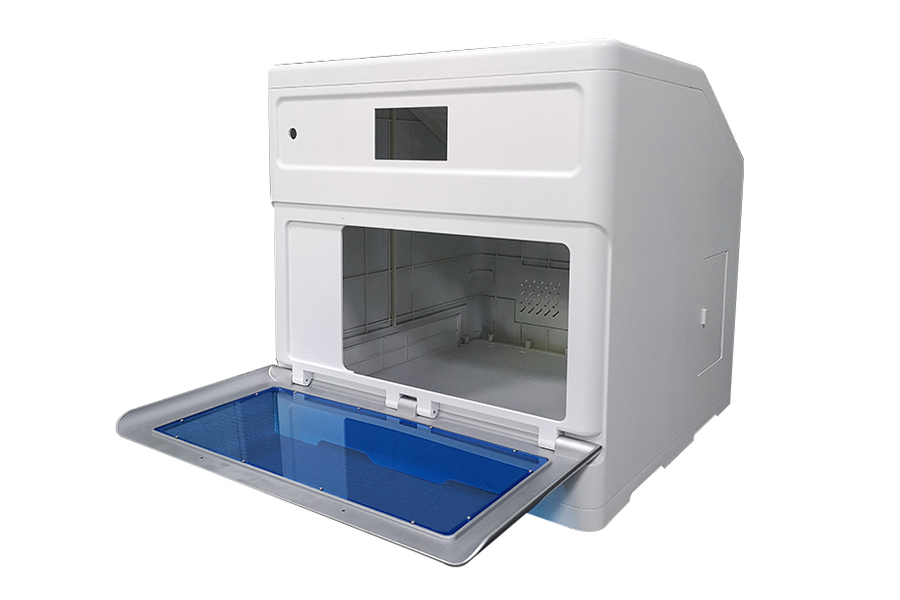

Stereolithography (SLA)

Stereolithography is the earliest technology used in 3D printing. They use a computer-controlled laser beam controlled by software. They use excess liquid plastic, which hardens after being deposited. They are commonly used in the medical field to make anatomical parts.

Features:

- They provide accurate and precise parts.

- They offer smooth surface finishes.

- They provide tight tolerances.

Price range: $3,500 – $11,000

Pros:

- SLA materials such as castable resins are readily available.

- Quality finishes make them suitable for printing prototypes.

- They can print complex patterns.

Cons:

- They are not environmentally friendly.

- Their high precision means they need a lot of attention.

- They are costly to acquire and maintain.

Selective Laser Sintering (SLS)

Selective laser sintering mode of 3D printing works by sintering a layer of material onto the heated bed covered by nylon-based powder. Once the layer is fused, a new layer of the powder is distributed before the material is distributed again.

Features:

- The models produced are stiff and sturdy.

- They can endure wear and tear and are impact resistant.

Price range: $40,000 – $50,000

Pros:

- They provide fast turnaround times.

- They can be used with a wide range of materials.

- They offer high-resolution materials.

Cons:

- Parts can have a grainy surface without post-processing.

- They take a long time to cool hence lengthening the printing time.

- They are expensive to acquire, and the materials they use are also costly.

Fused Deposition Modeling (FDM)

In fused deposition modeling 3D printers, melted material is selectively deposited on a predetermined path, one layer after another. Thermoplastic polymers in the filament are the most common materials used.

Features:

- They allow the creation of complex and intricate objects.

- Once the model is made, the structure is withdrawn.

Price range: $2,500 – $10,000

Pros:

- They support cloud server printing.

- They are cost-effective in acquiring and maintaining.

- They are less complex to operate.

- The filaments are reusable.

Cons:

- Often the models can warp or shrink.

- The quality produced is relatively low.

- They are very slow in printing.

Target market for 3D printers

The global revenue of 3D printers is expected to grow with a CAGR of 29.48% by 2026 to $63.46 billion. This means that in 2026 15.3 million units will be sold as opposed to the 2.1 million sold in 2020. The largest market for 3D printers is in North America, while the fastest-growing market is in the Asia Pacific region. The ease of fabrication of parts industrially and advancements in the material composition will cause the industry to grow further. Also, the reduced cost of additive manufacturing machines will contribute to this growth.

Conclusion

3D printers are recent and have taken the market by storm. While the growth prospects are favorable, like all commodities, they are subject to different market forces such as supply and demand. This article has highlighted identifying a good 3D printer, their current global market share, and the different types of 3D