Homogenization is a key process that is used in a number of industries, including food, pharmaceuticals, biotechnology, and cosmetics. Homogenizers are at the core of this process, and there are various types available on the market that are designed for different applications and industries.

In this article, we’ll look at high-pressure homogenizers, starting with what they are and how they operate. We’ll then explore the global high-pressure homogenizer market, analyzing current market size, key drivers, and projected market growth. The article will then offer a buying guide for retailers to use when selecting high-pressure homogenizers to add to their inventories in 2025.

Table of Contents

What are high-pressure homogenizers?

What are the benefits of high-pressure homogenizers?

Overview of the global high-pressure homogenizer market

Buying guide for high-pressure homogenizers

Key takeaways

What are high-pressure homogenizers?

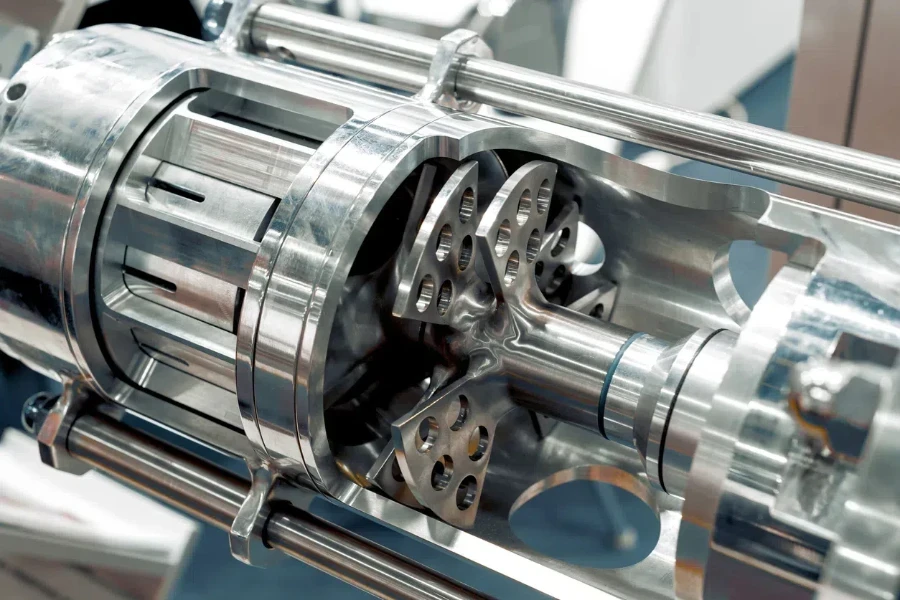

High-pressure homogenizers (HPHs) are pieces of equipment that are used in high-pressure homogenization, where large volumes of liquid samples are processed thoroughly and reproducibly.

High-pressure homogenizers do this by forcing the liquid samples through extremely narrow valves or openings. The process generates impact and shear forces that result in uniform particle size reduction, typically in the nanometer range.

What are the benefits of high-pressure homogenizers?

High-pressure homogenizers offer a range of benefits to users across various industries, such as:

- Enhanced stability of final products: They create homogenized products with very small, fine particles, which prevents the particles from falling out of solution, thus fostering the creation of stable emulsions and suspensions that help to extend the shelf life of final products.

- Improved texture and flavor: The uniformity and fineness of the homogenized product particles enhance product texture and improve the palatability of final products such as drinks, sauces, and dairy emulsions.

- Nano-suspension generation: HPHs can produce nanosuctions that are vital in pharmaceuticals and cosmetics because they increase bioavailability and enable targeted drug delivery.

- Consistency in product composition: For industries such as pharmaceuticals where it’s important for active ingredients to be evenly dispersed, HPHs ensure consistent distribution of particles in the mixture.

- Decreased cost: Effective high-pressure homogenization reduces the need for chemical and thermal processing, thus leading to overall cost savings and enhanced product safety.

Overview of the global high-pressure homogenizer market

According to a Verified Market Research report, the global high-pressure homogenizer market was valued at US$ 1.48 billion in 2023. This market value is projected to grow at a compound annual growth rate (CAGR) of 4.9% to reach US$ 1.94 billion by the end of the 2024–2030 forecast period.

Consumer trends, such as increased consumption of processed and packaged foods and growing demand for ready-to-consume products such as dressings, spreads, juices, and sauces, are key drivers of growth within the global HPH market. The pharmaceutical industry is also driving HPH market growth, as products from the industry are being used to alleviate rising illnesses caused by fast-paced lifestyles, such as diabetes and hypertension, as well as cardiovascular problems.

In terms of geographic distribution, North America is expected to continue holding the largest market share over the forecast period, followed by Europe and Asia-Pacific, respectively.

Buying guide for high-pressure homogenizers

With an understanding of the benefits of high-pressure homogenizers and their projected demand across different industries, it will now be crucial for retailers to choose the right type of homogenizers to add to their product portfolios. Below are some tips on how to do this:

1. Consider capacity

One of the first things that retailers should consider when selecting high-pressure homogenizers is the amount of product that potential users would need to homogenize per batch or hour. HPHs come in a wide range of capacities for different applications, from smaller-scale models that can be used in laboratories to larger-scale industrial units.

You would then select a homogenizer that best suits the average consumer or commercial buyer your business is targeting.

2. Look at pressure ranges

Depending on the product type that users are working with, the pressure required to achieve homogenization will be different. If, for example, the target consumers are buyers from industries that require smaller particle sizes and uniform distribution, then homogenizers that are capable of reaching high homogenization pressure (30,000 psi) would be required.

Thus, after looking at the desired particle size and the product type of consumers, buyers should seek out HPHs that are capable of reaching the required homogenization pressure.

3. Take note of the homogenization stages

Another critical area that HPH buyers should consider are the homogenization stages that the high-pressure homogenizer offers. Homogenizers can provide single-stage, double-stage, or multi-stage homogenization.

Single-stage homogenizers are designed with only one homogenizing valve, while double-stage homogenizers have an additional one, and multi-stage homogenizers have several. The advantage of multi-stage homogenizers is that particle size distribution is further refined and product stability is strengthened.

4. Choose between batch or continuous processing

It is also important for retailers to take into account the production requirements of their target customers. Some HPHs are better suited for batch production, while others are more suitable for continuous-flow processing.

For instance, if you are targeting consumers with high-volume production, like those in the food or dairy industry, then homogenizers that are designed for continuous production are best. However, if the consumers work with batches, such as those who conduct lab work, then homogenizers designed for batch production would be best.

5. Think about cleaning and maintenance

Beyond actual production, retailers should also consider the cleaning and maintenance of the different homogenizers on the market. Ideally, the best homogenizers to source would be those that are not only easy to use but also easy to clean and maintain.

This is important because the ease with which users can conduct cleaning and maintenance has an impact on ensuring that product quality is maintained and downtime is minimized.

6. Go for a sanitary design

On the note of cleanliness, retailers should also look to source homogenizers that come with sanitary designs and easy cleaning methods.

This is particularly crucial in the food and beverage and pharmaceutical industries that require strict sanitary procedures. Buyers can look for homogenizers that have automated systems like clean-in-place (CIP), which clean the interior surfaces of equipment without the need to disassemble the process.

7. Opt for aseptic processing

If the potential customers are users who process UHT and sterile products, then going for high-pressure homogenizer models that offer aseptic processing would be best.

The aseptic homogenization technique aims to minimize contamination in environments and does this by ensuring that the homogenization only takes place following heat treatment.

8. Evaluate data acquisition and control systems

Advancements in automation and control systems have provided certain homogenizer models with high-performance data acquisition and control functions.

Users will benefit from these advanced models because their integrated systems allow for real-time monitoring of pressure and temperature, as well as other key variables, ultimately helping to maintain consistency and reproducibility in processes.

9. Keep scalability in mind

Part of being a good retailer is being able to anticipate, plan for, and cater to the needs of clients. That is why, while sourcing HPHs for retail, you should opt for models that are suited for not only the current but also the future production needs of the users.

Retailers can choose homogenizer models that offer scalability features, enabling users to expand their industrial capacity without the need to buy new units and without sacrificing cell disruption quality.

Key takeaways

The prospects of the global high-pressure homogenizer market indicate that this will be a burgeoning market over the next decade; thus, investing in homogenizers for retailers presents opportunities for increased sales and profits.

But before adding high-pressure homogenizers to your inventory, it is important to consider key factors such as capacity, pressure ranges, homogenization stages, processing type, cleaning and maintenance, as well as design, in order to choose the right homogenizers for your customers.

To go through an extensive directory of potential suppliers, explore Alibaba.com and check the wide variety of high-pressure homogenizers available to find one that meets your customers’ requirements.