Plastic has become a part of our life as you can see so many products made of this material. What makes plastics a better material than others such as metal is that it is cost-effective, versatile, recyclable, and can be made into different colors. The demand for food and other consumer products is increasing day by day. To meet the demand for packaging products, many plastic machinery manufacturers from different parts of the world have come into the market. Some of these companies are even offering a few years of guarantee for their products.

In this article, we are going to look at the leading plastic machinery manufacturers in the world. Additionally, we will dig deeper into the demand, market share, and expected growth rate of the plastic industry.

Table of Contents

Overview of the plastic industry market

Types of plastic forming machines

The leading plastic machinery manufacturers

Conclusion

Overview of the plastic industry market

The main driving force of the demand for plastic products is the widespread need for packaging material.

As of 2022, the plastics market was valued at USD 457.73 billion, an increase from USD 439.28 billion back in 2021. This figure is expected to reach USD 643.37 billion by 2029, which manifests a CAGR of 5.0% during the forecast period. Automotive, electronics & electrical, and construction are just a few industries with high plastic consumption leading to global plastic market growth.

Japan is one of the countries with an above-average consumption rate of plastic products. It is believed that Japan will have around eight million tonnes of plastic waste in one year, mostly in the sea. Other countries with high plastic consumption include Brazil, Germany, the USA, and China.

Types of plastic forming machines

1. Plastic injection molding machine

This machine is used in manufacturing plastic products through the injection molding process. It has two main parts; the clamping unit and the injection unit. This machine is classified according to the type of driving systems used—mechanical, hydraulic, electrical, or hybrid.

The first injection molding machine was patented in 1872, so the technology employed over the years has progressed enormously. As of 2020, its global market share was estimated to be USD 10.3 billion. It is expected to grow at a CAGR of 3.6% to USD 12.3 billion by 2025.

2. Plastic extrusion machine

Initially developed in the early 19th century, the plastic extrusion machine converts raw plastic into a continuous profile. The process of extrusion produces items like thermoplastic coatings and wire insulation. There are three main plastic extrusion machines: ram extruders, single screws, and multiple screws.

The global market of plastic extrusion machines in 2021 was valued at USD 6.05 billion. It is expected to grow at a CAGR of 4.7% over the next five years to reach a value of USD 8.12 billion.

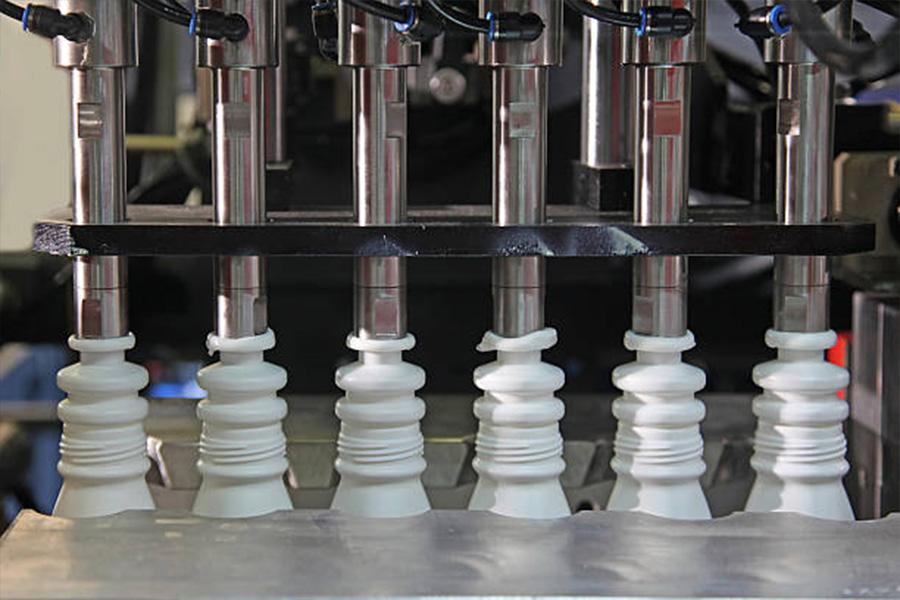

3. Plastic blow molding machine

The idea of glassblowing gave birth to the first plastic blow machine in 1938. A plastic blow machine forms hollow plastic shapes. The three main types of blow molding include injection blow molding, extrusion blow molding, and injection stretch blow molding.

The introduction of advanced technologies has made plastic blow molding machines more efficient, thus a proportionate increase in global demand. The market for this machine has an estimated value for the market of USD 4.65 billion in 2020. It is projected to reach USD 6.87 billion by 2030, with a CAGR of 3.8%.

4. Thermoforming

The first thermoforming machine was patented in the 40s. This machine heats a plastic sheet to form a specific shape in a mold and trims it into a usable product. The two main types of thermoforming include pressure forming and vacuum forming.

These machines range from simple to automated thermoforming machines capable of packing products into flexible or rigid packaging. They are extensively used across the globe to mold or seal containers. The market size is expected to reach USD 1.4 billion by 2032, with a projected CAGR of 4.3%.

5. Rotational molding

The first rotating mechanism was patented in 1855 in Britain. This machine molds plastics into hollow shapes. The process involves a heated mold filled with the charge being rotated to soften the material to disperse, thus sticking to the walls of the mold while forming a hollow part.

It is noted that the sales of rotational molding machines are increasing globally. The market is estimated at USD 890 million in 2022. It is expected to grow at a CAGR of 2.9% to reach USD 1 billion between 2022 and 2029.

The leading plastic machinery manufacturers

These are the leading plastic machinery manufacturers globally:

1. ARBURG

This is a German machine manufacturing company founded in 1923. It is among the leading industries worldwide producing hybrid and hydraulic plastic injection molding machines and turnkey systems. It has 33 locations in 25 countries, with the largest production station in Lossburg.

The Allrounder is the main injection molding range that provides various machine options, including hybrid machines and cube molds. The company also provides pickers and linear robotic systems. The estimated revenue of ARBURG is USD 7.5 million annually.

2. Haitian International

Based in Asia, the Haitian Group has two listed companies (Ningbo Haitian Precision Industry and Haitian International Holdings). It was founded in 1966 to ensure the flexibility of users’ machinery in manufacturing.

This manufacturer offers both hydraulic machinery and electrical products. Being one of the leading manufacturers of plastic molding machines, it has developed technologically-equipped machines that provide users with a wide competitive edge.

Haitian International reports that as of 2021, its sales amounted to RMB 16 billion, up 35.7% compared to the previous year.

3. Guangdong Yizumi Precision Machinery

This company has manufactured its products in Foshan, China, since 2002. As an established multi-corporation, it produces injection molding machines, rubber injection molding machines, die-casting machines, high-speed packaging systems, and robot automation integrated systems.

The company has both domestic and overseas markets for its products. As such, it currently has a revenue of USD 548 million.

4. Husky Injection Molding Systems

This global corporation was formed in 1953, with its main manufacturing headquarters in Canada. Additional manufacturing stations are in the USA, Switzerland, Luxembourg, China, and the Czech Republic. It also has three technical centers in Shanghai, Japan, and Luxembourg.

The company offers machinery and systems that produce medical products, beverage packing, and other consumer products. Husky offers factory planning, system integration, and proper asset management on value-adding services. It has an estimated annual revenue of USD 8.6 million as of 2021.

5. Chen Hsong Group

This machining company is headquartered in Hong Kong, China. Its main manufacturing, research, and development centers are at the Chen Hsong Industrial Park in Shenzhen, China. Other operational facilities are located in Ningbo, Taoyuan, and Taiwan.

Having been established in 1958, it has been one of the largest manufacturers of injection molding machines in the world. This follows a constant pursuit of innovations and technological incorporation in their manufacturing processes. It currently has an estimated revenue of USD 367 million.

6. Dow Chemical

This is an American-based multinational company headquartered in Midland, Michigan. It specializes in producing plastics, chemicals, coatings, catalysts, and agricultural products. It is highly ranked among polyethylene (PE) resin’s top global suppliers. It is also the largest manufacturer of polyalkylene glycols and chlorine.

Dow Chemical operates in over 160 countries. In 2018, it had a revenue of around USD 60.278 billion, putting it on the global radar.

It is among the companies that have invested in technology-based products that have greatly impacted other major sectors like packaging, transportation, agriculture, construction, and consumer care.

7. Sumitomo Demag

Bavaria, Germany, is where Sumitomo Demag is headquartered. The company has four plants located in Germany, China, and Japan. They developed their first single-screw injection molding machine in 1956. Over the years, they have improved their technology, and now they manufacture all-electric hydraulic and hybrid injection molding machines.

Additionally, Demag offers robotic systems to boost the machines’ overall performance. One of the plants in Thuringian Wiehe specializes in producing more efficient smaller-sized electric injection molding machines.

The company’s revenue in 2021 was valued at EUR 808 million. An increase of 17.4% from EUR 688 million in 2020.

8. Engel

Engel Group was founded in 1945 and manufactures plastic injection molding machines. The company has nine production zones, with its headquarters at Schwertberg, Austria.

The injection molding machines are both electric and hydraulic models. The company also offers various turnkey solutions. The range of specialist injection molding processes suits different materials, thus diversifying plastic production.

Engel is ranked among the world’s largest manufacturers of injection molding machines. It is reported that the company recorded a revenue of USD 1.5 billion in the financial year 2021/2022.

9. KraussMaffei

KraussMaffei has been in operation since 1838. The headquarters is located in Munich. The company is among the world’s leading producers of systems and machines manufacturing rubber and plastic.

They have ensured uniqueness involving strong innovation in their range of products. Advanced technology has been employed in injection molding, extrusion and reaction process machines.

The company caters to buyers in the automotive, packaging, construction, and medical industries. This has ensured the company an estimated revenue of USD 1 billion.

10. Nissei Technology Corporation

Nissei Group was founded in 1923 and was later incorporated in 1957. It is headquartered in Kobe, Japan. The operating segments include Japan, Asia, and the United States. The company mainly designs ultra-precision plastic optical components and molding machinery.

Among the products are horizontal, vertical, and special injection molding machines.

They also offer molding support systems and quality control systems to make plastic production processes more efficient. The company mainly caters to the electronics and automotive industries.

This company has a revenue of JPY 49.65 billion, which is attributed to the manufacturing and selling of injection molding machines and peripheral equipment.

Conclusion

Plastic machinery provides the buyer with various materials and processes for manufacturing various plastic products. Some can produce simple to complex products that are cost-effective and environmentally friendly. Eventually, a buyer wants machinery that meets their needs and performance requirements. To get this kind of machinery, visit Alibaba.com.