Direct-to-film (DTF) transfer printing is a popular method for creating high-quality, full-color designs on various surfaces. However, several factors can influence the quality of DTF transfer patterns. Understanding these factors and learning how to optimize them is essential for achieving optimal results in DTF transfer printing.

Without further ado, let’s dive into what affects the quality of DTF transfer patterns.

Printhead type and quality

Inkjet printers can produce various colors by mixing the four CMYK inks. However, the printed output’s quality heavily depends on the type of printhead used.

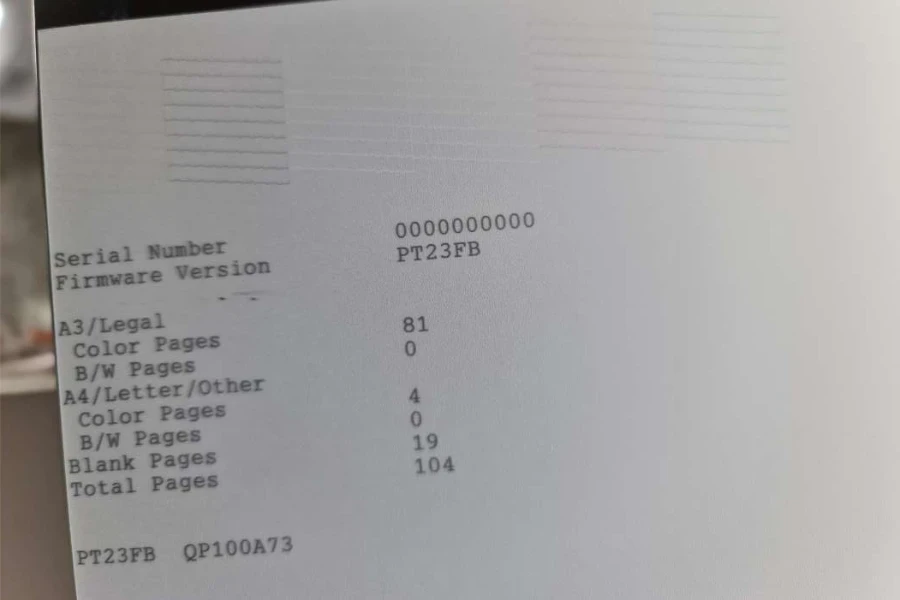

The printhead contains tiny electrical components and nozzles that hold the different ink colors and spray them onto the printing medium. The number of nozzle holes in the printhead can impact the printing speed and quality. Over time, the nozzle holes may become clogged with ink or contaminated with dust, resulting in defective printing.

It is recommended to replace the print head every 6-12 months. It would be best if you also ran a test strip to check its status. Continuous and complete lines with accurate colors indicate a good print head, whereas intermittent lines indicate the need for a replacement.

Software settings and printing curve (ICC profile)

The print head is not the only factor affecting print quality. Software settings and the printing curve also play a significant role. For optimal results, make sure that you set the correct parameters, including selecting the right printing curve.

The ink dot size and scale unit are also crucial. The size of individual ink drops impacts print quality; smaller drops offer better definition, whereas larger drops are ideal for quick, large-area printing. To achieve perfect color accuracy, use printer software with built-in curve calibration.

Image format and pixel size

The printed pattern is also influenced by the original image. If your image has been compressed or the pixels are low, the output result may not be what you expect. The printing software can only optimize the design if the source image is clear. Remember, the higher the resolution of the image, the better the output result.

Images in the PNG format are more suitable for printing, as they don’t have a white background (they have no background color). Other formats, such as JPG, are not quite ideal because it would be weird to print white background for a DTF design.

Ink quality

Inks can have different effects on printing quality. UV ink, for example, has a unique effect on various materials compared with DTF ink. Thus, matching your ink with the correct printing curve and ICC profile is essential.

Using DTF ink simplifies the printing process and guarantees the most accurate color. But avoid mixing inks of different types because it can cause printhead blockages. When choosing what ink to use, you should also consider the shelf life. It’s best to use opened ink bottles within 3 months and sealed ink within 6 months.

DTF transfer film

There is a wide range of DTF films available in the market, but not all of them are created equal. Generally, films with a more opaque coating tend to produce better results as they have a higher ink-absorbing capacity. However, some films have loose powder coatings that result in uneven prints, with certain areas being resistant to ink. These films can be challenging to handle.

In some cases, films may initially appear fine but then warp and bubble during curing. One particular type of DTF film seems to have a melting point lower than that of DTF powder, with the film melting before the powder at a temperature of 150°C. It’s possible that this film is designed for use with lower-melting-point powder. However, this may affect its washability at high temperatures. Another type of film became warped so much that it lifted itself up by 10 cm and caught fire.

To avoid such mishaps, you can opt to use transfer films made from high-quality polyethylene material with a thick texture and a special frosted powder coating that enables the ink to adhere to it and fix it in place. The film’s thickness ensures the smoothness and stability of the printing pattern, resulting in a high-quality transfer effect.

Curing temperature and adhesive powder

To ensure the firm attachment of the pattern to the substrate, the printed film with adhesive powder coating needs to be cured in a specially designed oven. The oven temperature must reach at least 110 degrees Celsius. Anything below that temperature may result in incomplete melting of the powder and a poorly attached pattern that can crack over time.

The oven must maintain the required temperature for at least 3 minutes to ensure complete curing. Take note that a high-quality oven is crucial for a successful DTF transfer.

Additionally, the quality of the adhesive powder affects the transfer result. Lower quality grades yield lower viscosity and result in foaming and cracking of the pattern. It is recommended to use a high-grade hot melt adhesive powder for optimal transfer quality.

Heat press machine and printing material

Last but not the least, it is important to pay attention to the operation and settings of the heat press for a successful pattern transfer. The heat press machine should be set to a temperature of at least 160 degrees Celsius to ensure complete transfer of the pattern from the film onto the printing materials (e.g., a T-shirt). If the temperature is not high enough or the heat press operation time is insufficient, the pattern may not be transferred successfully or may peel off.

Moreover, the quality and flatness of the printing material also have an impact on the transfer quality. For example, the higher the cotton content of the T-shirt to be printed, the better the printing effect. Ironing the T-shirt in a heat press before the transfer process is recommended to ensure it is entirely flat and moisture-free. This will ensure the best transfer results. Although there are no restrictions on cotton content for DTF printing, a flat T-shirt will allow for better pattern transfer.

In conclusion, several factors can affect the quality of DTF transfer printing. The quality and resolution of the original image, the type of ink and film used, the temperature and duration of the curing process, and the settings and operation of the heat press are some of the crucial factors that can impact the final result. It is essential to choose high-quality materials and equipment, follow the proper procedures, and pay attention to details to achieve the best possible transfer pattern quality.

Source from Procolored

Disclaimer: The information set forth above is provided by Procolored independently of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller and products.