To most people, a raw orange is just that—an orange. However, accountants see things differently and classify the item depending on its use. They will record it as a consumer good if sold directly or as a capital good if businesses use it to produce orange juice. This difference highlights a key point: capital goods are assets used to create other products, while consumer goods are the final products consumers buy.

This article will explore everything businesses need to know about capital goods and will offer tips on what to consider before choosing these essential items.

Table of Contents

What are capital goods?

What are the main types of capital goods?

What should businesses consider when buying capital goods?

Rounding up

What are capital goods?

Whatever physical assets companies use to make products or offer services fall under capital goods. While people buy consumer goods for personal use, capital goods are essential for every business’s operation.

Usually, accountants will list capital goods as property, plant, or equipment on financial statements. They will also track them for depreciation so businesses know when their capital goods are close to losing value or almost depleted.

Take a business that produces orange juices, for example. They may use up all their oranges during monthly production if they buy a truckload of raw oranges. Financial statements will show when the business should purchase more to keep things running smoothly. Similarly, the equipment used to process the oranges will wear out and eventually need replacement.

What are the main types of capital goods?

Businesses can categorize capital goods into five types, depending on their role and function during production.

Machinery and equipment

This category is probably the first thing anyone imagines when thinking about capital goods. Machinery and equipment include every tool businesses use for resource extraction, manufacturing, communication, and other functions. Some common examples include:

- Assembly lines

- Kitchen appliances

- Computer hardware and data servers

- Landscaping tools

- Industrial robots

- Processors

Raw materials and components

Another type of capital goods businesses need is raw materials and components. These are the products responsible for creating consumer goods or running machinery. Here are some great examples:

- Screws, nuts, and bolts

- Fabric, leather, and other upholstery

- Wood

- Cooking ingredients like flour, oil, sugar, and salt

- Gasoline

Vehicles

Companies can also consider vehicles as capital goods if they use them to move materials or products within a business. Examples of these include:

- Cars for transporting employees to job sites

- Delivery trucks

- Refrigerated trucks

- Tanker trucks

- Warehouse forklifts

- Cargo vans

- Utility trucks

- Cranes

Software

Software falls under capital goods when businesses use it to improve their operations. Unlike consumer software for personal use or entertainment, business software is necessary for boosting efficiency and productivity. Examples include:

- Enterprise resource planning (ERP) systems

- Computer-aided design (CAD) software

- Manufacturing execution systems (MES)

- Data analytics and business intelligence (BI) software

- Computer relationship management (CRM) software

- Financial management and accounting tools

- Supply chain management software

- Social media management programs

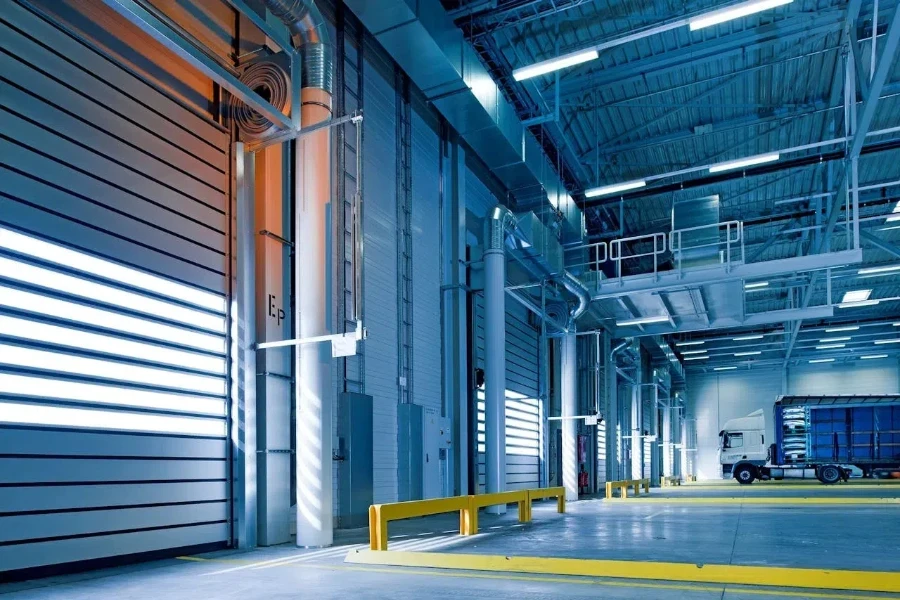

Facilities and structures

Facilities and structures provide the physical spaces where businesses operate, store products, and manage daily activities. Examples include:

- Warehouses

- Retail stores

- Data centers

- Manufacturing plants

- Office spaces and buildings

- Distribution centers

What should businesses consider when buying capital goods?

1. The business needs

Before businesses buy any equipment, they must clearly define their needs. Why would companies need that new laptop or printer? Is it essential, or just something that seems nice to have? It’s important to assess the specific purpose of the equipment, whether it’s for improving sales, enhancing office communication, speeding up decision-making processes, or automating tasks.

One surefire way businesses can complete this step is by listing the essential tasks they need to accomplish. Then, they can consider whether the equipment will help them achieve them or if there’s a better alternative (like renting). It’s a necessary step to help brands choose the right tools that effectively meet their business goals.

2. Equipment cost

The cost of something often reflects its value and efficiency. In other words, if businesses want the best, they must be prepared to pay for it. Knowing what the business needs will help brands understand the specific features and capabilities they should look for.

But while seeking the best deals is natural, sometimes cutting costs isn’t worth it. If the equipment is essential and offers significant benefits, it may be worth investing the extra money to ensure businesses get high-quality products that satisfy all criteria.

3. Level of personnel training

Another crucial factor is whether employees need training to operate the new equipment safely. Do they have the knowledge to use it effectively? Will they need additional training, and what would that cost? Having equipment no one can use is pointless, and letting untrained staff handle complex machinery is risky.

It’s like asking a high school student to run a dangerous nuclear plant, which will likely lead to mistakes, costly repairs, or even accidents. Proper training ensures work safety, maximizes the team’s potential, and helps retain skilled employees.

4. Maintenance cost

How much will it cost to keep this equipment running? Is the expense manageable, or will it strain the budget? Businesses must figure out how to minimize these costs effectively.

Although maintenance is crucial, it shouldn’t break the bank. When choosing capital goods, consider reliable options that require less frequent servicing. This way, businesses can allocate resources to more important aspects while keeping everything running smoothly.

5. Quality

It’s always good to prioritize quality over quantity. Quality equipment lasts longer and works more efficiently. Businesses must ensure the supplier they buy their capital goods from has good user reviews and offers equipment that meets high standards. Alternatively, brands can consult an expert to help guide them on the best choice based on the essential functions they need.

6. Power needs

When buying capital goods, remember that almost everything needs power to run. Business owners must ask themselves, “Do I have enough electricity to power that machine (like a high-power refrigerator for a restaurant)?” Once businesses know how much power they will need to run everything smoothly, they can explore how to do it efficiently or consider alternatives to keep energy costs in check.

7. Profitability

How much value will this equipment add to the business? Will it be worth more than what business owners are hoping for? Consider how much money the equipment could help generate (directly or indirectly) and compare that to the current situation without it to gauge profitability. Never buy capital goods just for the sake of it.

8. Depreciation rate

Consider how long the machine will last and whether it will still provide good value. Equipment’s longevity often depends on the materials manufacturers use to make it. For instance, machines with aluminum parts generally last longer than those with iron (as iron can rust). So, businesses must consider their equipment’s material and whether it can handle regular use without breaking down.

Rounding up

Capital goods are essential for the smooth operations of a business. However, capital goods sometimes require significant investment, meaning they are not something that businesses can buy on a whim. Thankfully, companies can avoid buying equipment they don’t need by considering the eight tips discussed in this article.