The glass processing machine you choose significantly impacts your company’s success. However, identifying and selecting the right glass processing machine can be challenging.

This article will offer a brief overview of the market for glass machinery, and then it will dive into four essential tips you need to keep in mind when sourcing glass processing machinery so you can confidently select the best models for your business.

Table of Contents

The market for glass processing machinery

4 tips for selecting glass processing machinery

Types of glass processing machinery

Conclusion

The market for glass processing machinery

The current glass processing machinery market size is estimated at US $1.8 billion. Glass processing machinery is critical in modifying glass for specialized purposes in a wide range of industries, including automotives, construction, consumer electronics, furniture, and solar energy.

The growth of these industries is expected to drive the global market demand for glass processing machinery, and with a compound annual growth rate (CAGR) 4.5%, the market size is expected to reach US $2.1 billion by 2026.

Geographically, in 2022, the U.S. market size is valued at US $369.7 million, representing 20.9% of the global market. On the other hand, the Asia pacific region is expected to register the highest growth rate, with China in particular projected to reach a market share of US $533 Million by 2026.

4 tips for selecting glass processing machinery

There is a lot of glass processing equipment available on the market. Here are the tips or factors to consider when choosing the right machinery for your business.

1. Determine the glass specifications and thickness

Firstly, it is important to select the machinery based on the size and scale of glass to be processed. For instance, in terms of the glass’s cross-section, choose the machinery according to the kind of glass you will be dealing with such as round glass, square glass, and angle iron.

Similarly, consider the state of glass that you will be working with when choosing the machinery such as whether you’ll be dealing with flat glass, art glass or laminated glass.

2. Choose the equipment model based on production needs

Secondly, you should aim to select glass processing machines based on your production needs. For instance, shape edging machines bring down glass edges. Buying this type of glass machinery may be good if your business deals with custom projects such as working with round windows, church windows, and high-architectural projects.

That said, it is key to establish your business needs before buying any glass processing machine, and ensuring the machine is suitable for the kinds of projects you will primarily be dealing with.

3. The level of stability and precision

It’s also very important to keep in mind that when selecting a glass processing machine, stability and precision are crucial factors to consider. The mechanical pieces of the machinery should be sturdy and flat, and its important to examine the alignment of the guide rails on either side.

In addition, establish how to prevent the mechanical parts from getting damaged and how to restore them following deformation. Typically, deformed mechanical parts affect the machinery’s stability and precision, resulting in inefficiency in production and low-quality output.

4. The machine’s functions

And finally, the functionality of the machine is key in determining its performance. For instance, if it’s a glass cutting machine, find out if the machine can automatically control the pressure and whether or not it has a lower knife limit feature. It is important to closely examine the machine’s function because it affects its capabilities and suitability to the kind of manufacturing you intend to do.

Types of glass processing machinery

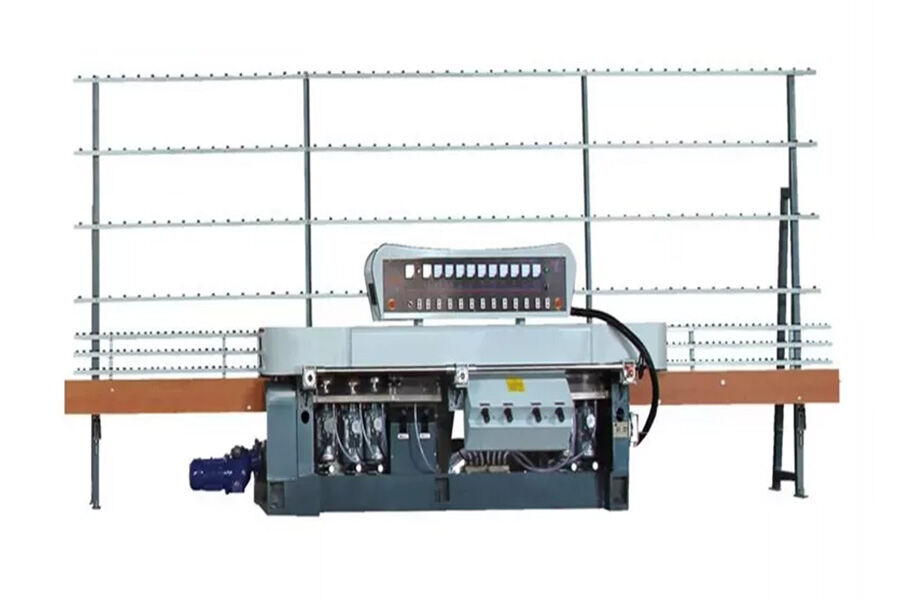

Glass edging machine

A glass edging machine is designed for grinding, seaming, and polishing the edges of cut glass. It is used for shower glass production, glass doors, and glass balconies.

The table below shows the specifications of a suitable glass edging machine.

| Glass edging machine | Specifications |

| Thickness of processed glass | 3-25mm |

| Minimum size of processed glass | 100×100 mm |

| Maximum size of processed glass | 2500×2500 mm |

| Processing speed | 0.5-6 m/min |

| Accuracy | High accuracy |

| Price range | $20,000 – $50,000 |

Features

- Customized features available

- It has an incredibly strong structural design

Pros

- It is easy to transport and install

- Compact and efficient use of space

- It is fast and accurate

Cons

- The middle part cannot be polished

Glass washing machine

A glass washing machine is mainly composed of a cleaning surface and drying equipment. Some of the glass washing machine parts include:

- Scrub

- Rinse

- Rinse water

- Cold

- Hot air, and

- Electric control system components.

Glass washing machines remove impurities from glass surfaces before preparing them for the next process, such as lamination.

The table below shows the specifications of a suitable glass washing machine.

| Glass washing machine | Specifications |

| Thickness of processed glass | 2-15mm |

| Maximum size of processed glass | 1200mm x 1200 mm |

| Cleaning speed | 1.5-6 meters |

| Accuracy | High accuracy |

| Price range | $3,000 – $10,000 |

Features

- The large glass washing machine has manual (pneumatic) glass flipped cars and light inspection systems

- There are two types of glass washing machines: horizontal and vertical

Pros

- Robust machine chassis

- Horizontal washers are efficient and long-lasting

Cons

- Horizontal washing machines take a lot of space

Glass drilling machine

Glass drilling machines are used for drilling flat glass. Typically, they are designed to drill glass of a thickness between 3 to 20mm.

The table below shows the specifications of a suitable glass drilling machine.

| Glass drilling machine | Specifications |

| Thickness of processed glass | 3-30mm |

| Minimum size of processed glass | 100×100 mm |

| Maximum size of processed glass | 2400x3500mm |

| Drilling diameter | Ø4-Ø160mm |

| Drilling depth | 0-1250mm |

| Accuracy | High accuracy |

| Price Range | $3,000 – $10,000 |

Features

- It has an automatic feeding function

- The position and speed can be adjusted

Pros

- It is easy to operate

- Traditional semi-auto or double-deaded models are affordable

Cons

- Skilled labor is required

Glass cutting machine

A glass cutting machine is designed to cut straight or irregular lines with high precision.

| OCKM | 3700 | 4000 | 6000 |

| Thickness of processed glass | 3-19 mm | 3-19 mm | 3-19 mm |

| Maximum glass cutting speed | 150 m/min | 150 m/min | 150 m/min |

| Maximum size of processed glass | 3700×2550 mm | 4000×2850 mm | 6000×3210 mm |

| Tolerance | ± 0.20 mm | ± 0.20 mm | ± 0.20 mm |

| Accuracy | High accuracy | High accuracy | High accuracy |

| Breaking bars | 2+1 | 3+1 | 3+1 |

| Price Range | $3,000-$4,000 | $3,000-$5,000 | $3,000-$6,000 |

Features

- There is minimal surface friction because of the air cushion system

- It has an automatic glass alignment system

- It comes with glass optimization software

Pros

- It has a fast and accurate cutting capabilty

- It has a system that allows the use of shape templates with laser sensors

Cons

- Mold manufacturing requires skilled labor

Conclusion

With so many models available today, selecting the right glass processing machine can be a difficult task. This article has therefore aimed to highlight the key factors to consider when buying glass processing machines, so that businesses can confidently select the right models.

For more information about glass processing machines, head over to the glass machines section on Alibaba.com.