Digital printing has revolutionized textile design and production methods by adding fascinating cost-effectiveness and efficiency to traditional printing. With the arrival of digital printers, textile printing has changed from labor-intensive and time-consuming methods to high-quality and streamlined techniques.

One of the popular methods that saw a turnout from the worldwide community is the Direct-to-Film (DTF) printing process, which enhances efficiency, and cost-effectiveness and opens new possibilities for sustainability and creativity. This blog will cover the basics of what DTF printing is and how it works, as well as some key features to look for when sourcing a new DTF printer.

Table of Contents

What is DTF printing?

Two main types of DTF printers

5 things to look for in a DTF printer

DTF printers for a beginner-friendly printing experience

What is DTF printing?

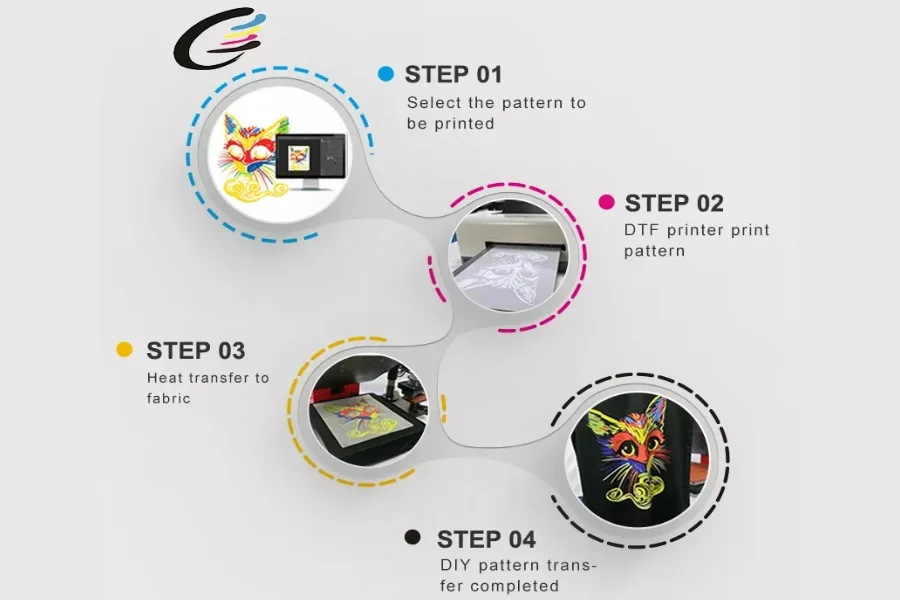

DTF printing is one of the most adaptable methods used in the print industry. The process involves transferring designs onto a special film (PET film) that facilitates design transfer. Once the design is on the film, it’s applied to the fabric using a heat press machine, along with the addition of hot-melt powder.

Unlike other methods, DTF can be used with more rigid fabric types such as polyester, fleece, classic cotton, and nylon with long durability. As a result, it produces lasting, vivid, and detailed prints without the need for intricate screen setups.

Take, for instance, DTG printing. While it provides high-quality prints and is perfect for custom clothing, it faces limitations with certain fabric types and can be slower for mass production. Similarly, sublimation enables full-color and all-over prints but is confined to polyester or polyester-blend fabrics and demands specific coatings on substrates.

Two main types of DTF printers

Two main types of DTF printers can be distinguished based on their mechanisms: one type employs rollers, while the other uses single sheets.

DTF printers with rollers

This type of DTF printer boasts a continuous feeding system where a roll of film is connected to the printer, making the printing process automation more seamless. The fabric is fed into the printer using a set of rollers that synchronize with the printing process. As the fabric passes over the printer, the desired design is imprinted onto it.

DTF printers with rollers are perfect for printing on expansive fabric panels and continuous rolls, making them an excellent choice for industrial-scale textile printing. This not only saves time but also minimizes the need to insert individual films into the DTF printer. Furthermore, these printers allow for efficient production, reducing manual intervention and increasing overall output, which is particularly beneficial for large-scale operations.

DTF printers with single sheets

DTF printers with single sheets differ from those with rollers, as their mechanism is based on placing the fabric onto the printer bed or platen, with a single sheet of transfer film laid on top of it.

The design is transferred from the film to the fabric using a heat and press machine. These single-sheet DTF printers are ideal for small-scale production or on-demand printing, making them perfect for beginner business owners starting with a limited budget and a smaller customer base.

The distinction between the two types of DTF printers offers options for various production needs. Single-sheet DTF printers have limitations, as they print in smaller quantities and require continuous feeding. On the other hand, DTF printers with rollers are an excellent choice for factory owners and mass producers, catering to larger-scale operations and higher production demands.

5 things to look for in a DTF printer

Selecting the right DTF printer is a critical decision for digital textile businesses, as it directly impacts their ability to maximize productivity and deliver top-notch results. Key aspects such as capacity, speed, and high-quality printing should be carefully considered.

As the needs of the business evolve, the desired features in a DTF printer may change as well. In this blog section, we’ll delve into the top five essential features to look for in a DTF printer while keeping in mind the ever-changing demands of the industry.

Printing speed

DTF printers are known for their high-speed printing capabilities, but many factors influence the production speed of a DTF printer. One such factor is the DPI of the pattern. DPI refers to the number of dots per inch in the printed image. There is a trade-off between DPI and printing speed, as higher DPI requires more ink droplets and precision, which can slow down the printing process.

Another factor that impacts production speed is the printhead’s capabilities. The dots per inch of the printhead can vary from one model to another. For example, DTF inkjet printers are specifically designed for high-speed printing with high DPI, while other models may have limitations on the maximum DPI they can achieve, despite their high speed.

Specialized software

A specialized DTF printing software is crucial for the printing details and process, as it converts the digital design into a file that the printer can comprehend. The software also provides RIP (Raster Image Processor) features, which offer numerous benefits such as color management, halftone settings, and ink optimization for accurate and high-quality prints.

RIP-based DTF printers are capable of handling CMYK (cyan, magenta, yellow, and key/black) and white colors. This type of DTF printer is designed to support printing with multiple ink channels, including white ink, to achieve vibrant and opaque prints on dark or colored fabrics. Additionally, the RIP software can administer color profiling, ink levels, and drop sizes to ensure the highest print quality possible.

Variety of printing colors

When considering a DTF printer, one key feature to look for is its capacity to offer a diverse range of printing colors. The CMYK color model is the standard and provides a wide variety of colors to work with. However, to truly set their textile designs apart and create eye-catching prints, it’s essential for businesses to consider a printer that goes beyond the standard CMYK model.

The addition of fluorescent inks to a DTF printer’s color capabilities can significantly enhance the visual impact of the printed designs. Fluorescent inks, such as neon or vivid colors, can make digital textile prints stand out and attract attention. When searching for the perfect DTF printer, prioritize fluorescent models that offer this expanded color range.

Hot-melt powder

The hot-melt powder is a widely-used adhesive in textile printing and fabric bonding applications, often combined with a DTF printer to directly transfer designs onto fabric.

This unique thermoplastic material stays solid at room temperature but melts and turns adhesive when heated by a press and heat machine. There are two main types of hot-melt powder: black and white.

Choosing the appropriate hot-melt powder depends on factors like clothing color, fabric type, and desired adhesion strength. The black hot-melt powder works well for dark designs on light fabrics, while white powder is suitable for light designs on dark or colored fabrics.

Advanced configurations

Advanced features can significantly improve the DTF printing process, image quality, and overall efficiency, such as:

- Micro-piezo inkjet technology: this technology provides excellent color accuracy and sharpness by forcing ink droplets out of the printhead nozzles.

- White-ink automatic circulation system: it enhances the opacity of colors on dark fabrics while preventing printhead nozzle clogging.

- Preheat function: this allows the printer to heat the fabric before printing, ensuring better ink absorption and adhesion while minimizing the risk of bleeding or smudging.

- Sensors for temperature and humidity: this helps maintain consistent printing results and prevents issues such as ink drying too quickly or too slowly.

- Smoke purifying function: it extracts and filters out chemical gasses, ensures a safe and healthy workspace for operators, and minimizes the impact on the environment.

- Printing size: DTF can print in a wide range of sizes for small items and large ones, it can handle fabric widths ranging from 60 centimeters (24 inches) to 180 centimeters (70 inches) or more depending on the roll or the feeding mechanism capacity.

DTF printers for a beginner-friendly printing experience

DTF printing is all about simplicity, and that’s why it’s one of the most popular textile printing methods for beginners. It’s not just for large-scale professionals anymore—it’s for anyone who wants a simple, reliable way to print designs onto fabrics. Start sourcing a wide variety of DTF printers from leading suppliers on Alibaba.com!