Cement plastering machines have brought a revolutionary change to the construction industry by automating and streamlining the process of applying cement-based plaster. These machines have many advantages, including increased productivity, improved consistency, and reduced labor costs. However, the market is flooded with numerous manufacturers, making it challenging to find the ideal machine that meets your requirements.

This article will explore the essential factors when purchasing cement plastering machines. It will also discuss the market share of spraying and plastering machines and examine the different types of machines available.

Table of Contents

Market share of spraying and plastering machines

Types of cement plastering machines

Factors to consider when buying cement plastering machines

Conclusion

Market share of spraying and plastering machines

A report published by Business Wire shows that as of 2021, the market for spraying and plastering machines demonstrated its robustness with a valuation of $2.5 billion. The industry is poised for further growth, projected to reach an impressive $4.5 billion by 2027. This anticipated expansion reflects a compound annual growth rate (CAGR) of 6.1% from 2021 to 2027.

The demand for cement spraying machines has increased due to a growing emphasis on efficiency and productivity in construction, driving the adoption of mechanized and automated processes. Additionally, these machines reduce labor costs by minimizing manual labor and streamlining the plastering process, leading to cost savings and improved profitability.

Regions with high demand for cement plastering machines include North America, Europe, Asia-Pacific, Latin America, the Middle East, and Africa.

Types of cement plastering machines

1. Worm drive plastering machine

A worm drive plastering machine uses a worm gear mechanism to deliver and apply cement-based plaster. It features a screw-like rotating shaft that pushes the plaster material forward, ensuring a consistent flow. This type of machine is known for its reliability, ease of use, and ability to handle various types of plaster. It offers precise control over the plaster flow rate and is suitable for small and medium-sized projects.

2. Piston-type plastering machine

Piston-type plastering machines use a piston-driven system to pump and apply plaster. The machine’s motor drives a piston, creating the pressure to push the plaster material through a nozzle. This type of machine is highly versatile and can handle different types of plaster, including cement-based plaster. It offers excellent control over the flow and pressure of the plaster, allowing for precise application on various surfaces.

Piston-type machines are favored for their efficiency, durability, and adaptability to different plastering needs.

3. Screw pump plastering machine

Screw pump machines utilize a screw mechanism to pump and deliver plaster material onto surfaces. These machines feature an auger-like screw that moves the plaster material through a cylinder, generating pressure for the application.

Screw pump plastering machines are renowned for their efficient and continuous plastering process. They are suitable for indoor and outdoor plastering tasks and are often preferred for larger projects due to their high output capabilities.

4. Continuous mixer plastering machine

Continuous mixer machines combine mixing and pumping plaster functions in a single unit. They have a continuous supply of mixed plaster material, eliminating the need for separate mixing equipment. The mixer continuously blends the plaster components, ensuring a homogeneous mixture.

Mixed plaster is then delivered directly through a hose or pipe for application. Continuous mixer plastering machines offer convenience and time-saving benefits. They are also well-suited for projects requiring a consistent mixed plaster supply.

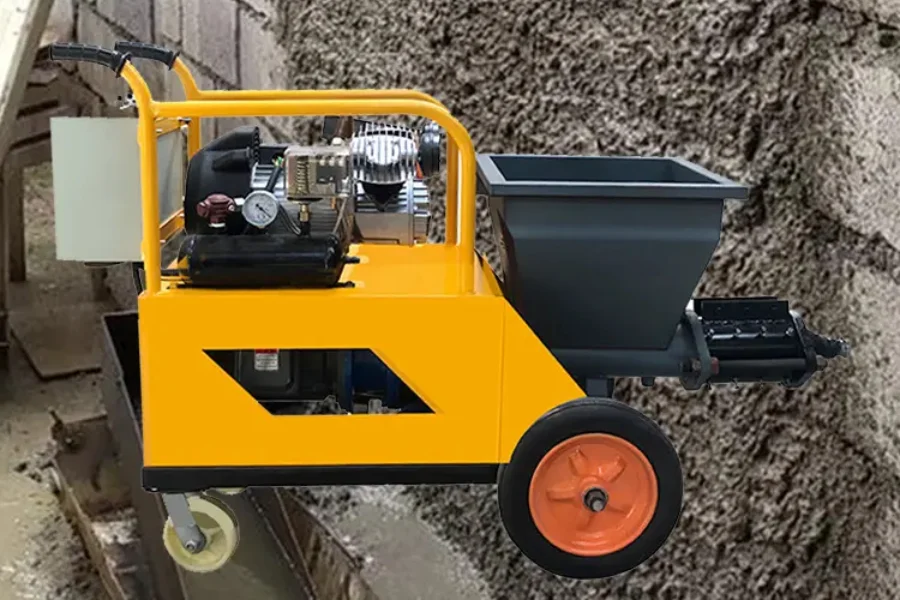

5. Spray plastering machine

Spray plastering machines use compressed air or hydraulic pressure to atomize and spray plaster onto surfaces. They feature a spray gun or nozzle that propels the plaster material onto the target area.

Spray plastering machines are highly efficient for covering large surface areas quickly and achieving a smooth finish. They offer excellent control over the spray pattern and allow for adjustable settings to cater to different plastering requirements. This type of machine is commonly used for projects such as wall coatings, ceiling plastering, and exterior rendering.

Factors to consider when buying cement plastering machines

1. Types of machine

Thoroughly assess the different types of cement plastering machines available in the market, such as worm drive, piston-type, screw pump, continuous mixer, and spray plastering machines. Carefully consider the features, capabilities, and application methods of each machine. Assess their versatility and adaptability to different plastering materials. By conducting a thorough assessment, you can determine which machine best suits specific plastering requirements, ensuring efficient and effective performance.

2. Price

You must look beyond the initial purchase price and consider the long-term benefits and return on investment the cement plastering machine can provide. Evaluate factors such as the durability of the machine, its performance capabilities, and the potential cost savings it can offer over its lifespan. The average price of cement plastering machines can vary depending on the type, brand, and features, ranging from around $2,000 to $20,000.

3. Durability

As you evaluate cement plastering machines, carefully analyze their build quality, construction materials, and overall durability. A durable machine is designed to withstand the demanding conditions of construction sites and deliver consistent results over an extended period. These machines are typically engineered to last up to 15 years, offering a reliable solution for plastering needs.

4. Capacity

Consider the machine’s capacity in terms of plaster material holding capacity, pumping rate, and coverage area. A cement plastering machine with sufficient capacity will work efficiently without frequent interruptions or the need for frequent material refills. On average, worm-drive plastering machines’ holding capacity can range from approximately 30 to 70 liters, and piston-type plastering machines have a holding capacity of around 40 to 100 liters.

Screw pump plastering machines’ holding capacity can range from approximately 80 to 200 liters, while continuous mixer plastering machines range from around 100 to 300 liters.

5. Speed

Take into account the machine’s pumping rate and application efficiency. A faster machine can have a substantial impact on productivity, enabling the completion of projects more efficiently and meeting project deadlines. The average speed of these machines can vary depending on the specific type and model. Generally, the pumping rates can range from 10 to 60 liters per minute. However, it is important to note that the exact speed may differ based on factors such as the viscosity of the plaster material, the machine’s power and design, and the application technique.

6. Applicable materials

Different cement plastering machines are designed to work with specific types of plaster, such as cement-based or gypsum-based plasters. Choosing a machine compatible with the plaster material you intend to use ensures optimal performance and efficient application. It ensures that the machine has the necessary components and settings to handle the specific consistency and texture of the plaster material, resulting in a smoother and more successful plastering process.

7. Energy efficiency

Prioritize energy efficiency by selecting cement plastering machines with optimal performance while consuming minimal power. The machine’s energy rating or specifications ensures that it operates efficiently and helps minimize energy costs. By opting for an energy-efficient machine, you can save on operational expenses and contribute to reducing the environmental impact associated with energy consumption.

Conclusion

Choosing the proper cement plastering machine is essential for efficient and high-quality plastering results. Factors such as machine type, price, durability, capacity, speed, compatibility, and energy efficiency should be carefully considered during the purchasing process. Evaluating these factors helps you select machines that meet your specific requirements and enhance productivity and profitability. To explore a wide range of cement plastering machines, visit Alibaba.com.