Manufacturing industries use hobbing machines to cut and also to shape gears. These machines are essential tools that produce high-quality gears, mostly used in aerospace, robotics, and automotive industries. Only an ideal hobbing machine can produce the needed results, which makes it important to ensure you purchase the right product.

This article will discuss types of hobbing machines available and give an insight into the tips buyers need to consider when buying suitable machines. Additionally, it will discuss the market share, size, and demand for hobbing machines worldwide.

Table of Contents

Gear hobbing machine market share

Types of hobbing machines

Tips for buying the right hobbing machines

Conclusion

Gear hobbing machine market share

According to MarketWatch, the market size of hobbing machines was valued at USD 663.72 million in 2021, and it is expected to reach USD 796.2 million by the end of 2027. This shows the market is expected to expand at a compound annual growth rate (CAGR) of 3.08%.

The increase in demand for hobbing machines is caused by various factors, including increased demand for manufactured goods, particularly in the automotive, aerospace, and heavy machinery industries. As these industries grow and expand, the need for hobbing machines is expected to rise even further.

Advances in technology, particularly in automation and computerization, have led to the development of more efficient and precise hobbing machines. These machines offer higher accuracy and productivity, making them more attractive to manufacturers who want to increase their output while maintaining quality.

The trend toward customization and personalization in various industries has increased the demand for custom gear. Hobbing machines are an essential tool for producing custom gears, so their demand has risen in response to this trend.

Regions with high demand for hobbing machines include Asia-Pacific, Europe, Latin America, North America, Africa, and the Middle East. The Asia-Pacific region, particularly China, Japan, and South Korea, is the largest market for hobbing machines. The area has a well-established manufacturing industry, and the demand for hobbing machines is high due to the growth of the automotive and aerospace industries.

Types of hobbing machines

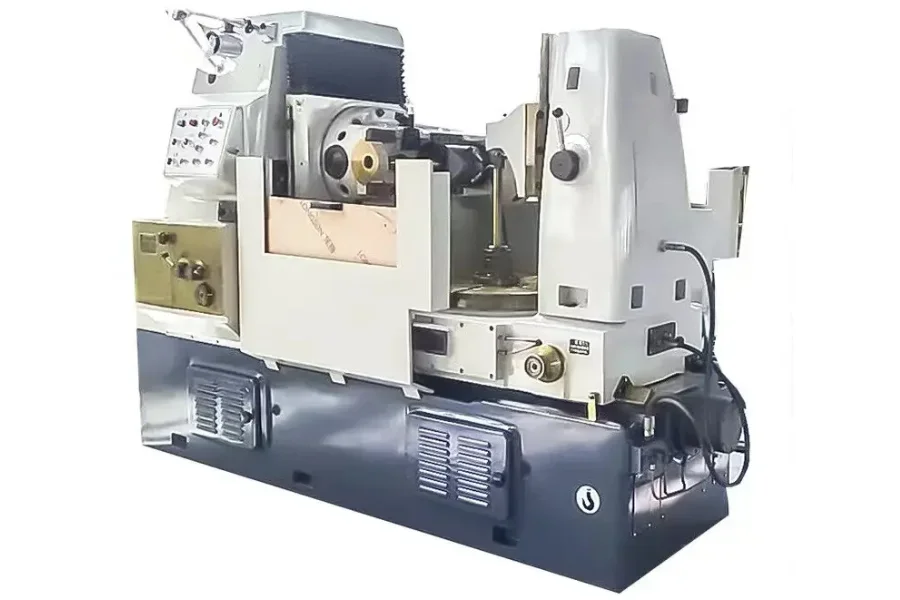

1. CNC hobbing machines

Computer Numerical Control (CNC) hobbing machines are highly automated machines that are controlled by computer software. They offer high precision and accuracy, making them suitable for producing complex gears with tight tolerances. CNC hobbing machines can perform multiple cutting operations and produce various sizes and shapes of gears. They are used in high-volume gear manufacturing, including automotive and aerospace industries.

2. Vertical hobbing machines

Vertical hobbing machines are designed to produce large gears with diameters of up to 12 meters. They are used in industries such as wind energy, shipbuilding, and mining, where large gears are required. The vertical design of the machine allows the gear blank to be mounted on a vertical table, making it easier to produce large gears.

3. Horizontal hobbing machines

Horizontal hobbing machines are designed to produce smaller gears with diameters of up to 2 meters. They are used in automotive, aerospace, and robotics industries, where smaller gears are required. The horizontal design of the machine allows the gear blank to be mounted on a horizontal spindle, which rotates the gear blank while the hob is held stationary.

4. Gear shaping machines

Gear shaping machines produce gears with complex shapes, including internal gears and gears with non-circular shapes. They are slower than hobbing machines but offer high precision and accuracy. Gear shaping machines use a cutter shaped to the required gear profile, which is pressed against the gear blank to cut the teeth.

5. Thread milling machines

Thread milling machines are used for cutting threads on gears. They are used in aerospace, automotive, and medical industries, where high-quality threads are required. Thread milling machines use a milling cutter that is designed to cut the required thread profile on the gear.

Tips for buying the right hobbing machines

1. Cost

To ensure you select the right hobbing machine, you need to determine your budget and choose machines that fit within it. Generally, smaller and simpler hobbing machines can range from USD 10,000 to USD 50,000, while larger and more complex machines can range from USD 100,000 to USD 500,000 or more, depending on size, complexity, and features. Higher-priced machines often come with additional features, capabilities, and a longer lifespan, but this may only sometimes be necessary.

2. Space available

When selecting a hobbing machine, it is crucial to consider the space available in a facility, as it will determine the size of the machine you can purchase. You should also consider the machine’s size, weight, and shape to ensure it will fit within your facility. Check the dimensions and specifications of the hobbing machine as well.

3. Speed

Hobbing machines typically have a range of speeds, depending on the machine’s size, power, and required gear specifications. Smaller hobbing machines may range from 10 to 1,000 RPM, while larger machines can have a range of speeds from 50 to 1,500 RPM or higher. The speed of the machine will affect the production time, so it is vital to choose a machine that can produce the number of gears needed within a reasonable timeframe.

4. Durability

A hobbing machine that can withstand heavy use and last for years is a wise investment. Look for machines made from high-quality materials that can resist wear and tear from continuous use. The number of years a hobbing machine can last can vary based on various factors such as the machine’s construction, usage frequency, maintenance, and environment. However, a well-maintained hobbing machine can last up to 20 to 30 years or more, depending on the specific machine and usage conditions.

5. Capacity

When choosing a hobbing machine, it is vital to consider its capacity to produce gears. The capacity can affect production output, so choosing a machine that can meet production needs is crucial. Consider the machine’s maximum and minimum production capabilities and ensure that they match the production requirements. This will help avoid any potential production bottlenecks or delays.

6. Precision and accuracy

Precision and accuracy are crucial in a hobbing machine to produce high-quality gears. It is important to ensure that the machine can produce gears with the required tolerances. To do this, consider the machine’s accuracy and precision capabilities, including its maximum allowable error and repeatability. Look for a machine that can consistently produce gears with the desired specifications and ensure that the machine’s accuracy and repeatability meet your requirements.

7. Applicable material

The hobbing machine must suit the material used to produce the gears. Buyers must ensure that the machine can work with the required materials, including ferrous and non-ferrous metals. Consider the machine’s cutting capabilities, including the cutting speed and power, to ensure that it can cut through the required materials with ease.

Conclusion

To make the right decision when choosing the ideal hobbing machines, it is crucial to consider several factors. These include the budget, space availability, speed, durability, suitability, capacity, precision and accuracy, and applicable material. Considering these factors, you can find a hobbing machine that aligns with your production needs and requirements. Visit Alibaba.com when you need to purchase hobbing machines in bulk.