Hay balers are used as the latter part of the harvesting process to compress hay into either a rectangular or round shape for easy handling. Whether the farmer prefers rectangular or round depends on how they intend to use the hay later.

This article looks at the different hay baling machines that are used for each type, explores their functionality, and looks at some of the models available.

Table of Contents

The global market for hay balers

What is a hay baler?

What to consider when selecting a hay baler

Examples of hay balers available online

Final thoughts

The global market for hay balers

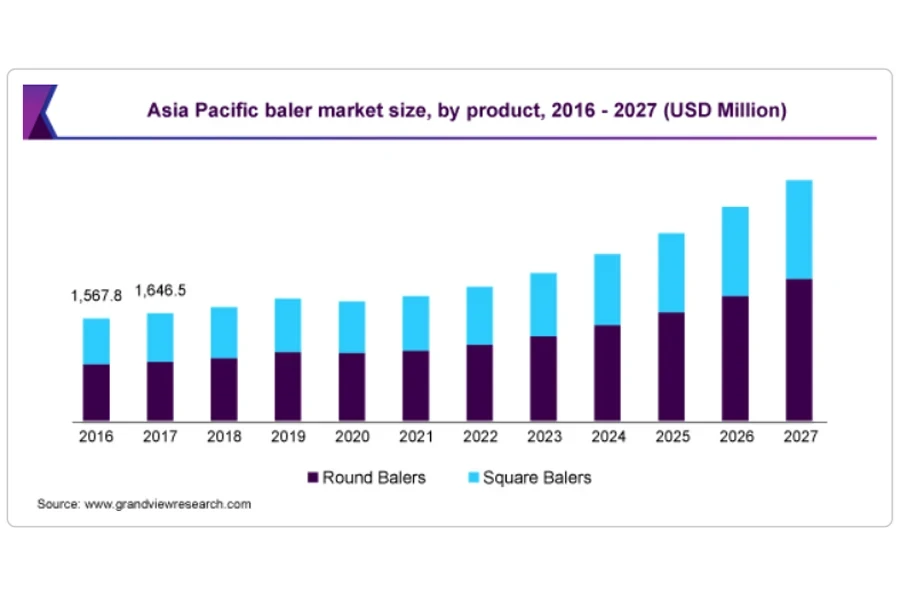

The global market size for hay balers is growing positively, in part due to an increasing demand across Asia-Pacific. The global hay baler market had a value of USD 5.1 billion in 2019, with round balers having a higher market share than square balers at 55.2%. This is expected to grow from 2020 to 2027 at a projected compound annual growth rate (CAGR) of around 8.9% to a value of almost US $9 million.

What is a hay baler?

Hay, as a byproduct of harvesting grain, is used as animal feed, for covering the floor of stables and barns, and as insulation to keep animals warm in cold weather. A hay bale is compressed hay that is tied or wrapped into a convenient size and shape for storage or use. Hay bales can be plastic-wrapped so that they can be stored or remain in the field without getting wet or damaged by rain. They are also often wrapped and stored wet to be allowed to ferment for silage.

Hay balers are towed behind a tractor, where they may use the power take-off shaft (PTO) and tractor hydraulics, or have their own hydraulics, to operate the baling. As the baler is towed, the front of the baler rakes up the hay from the field and feeds it into the baling system. The bale is produced by compressing the hay, and the bale is then ejected from the rear of the baler.

There are two different types of hay balers to produce two different types of bales. ‘Round hay balers’ compress the hay into a round (actually cylindrical) shape. ‘Square hay balers’ compress the hay into a square (actually rectangular) shape.

Round/cylindrical hay balers

Round hay balers pick up the hay from the field and then roll the hay into a cylinder. They can produce bales of either 4 ft (1.2 m) or 5ft (1.5 m). They can also pack the hay tightly as a hardcore bale or less tightly as a softcore bale. Larger or more tightly packed bales will obviously weigh more than those that are smaller or less tightly packed, and the larger bales can weigh up to 1 ton, especially if wet.

The round bale is compressed by rotating the hay either with rubber belts or rollers. As the hay is collected, it is rolled in the bale chamber, wrapping from the center, and as it compresses, it builds up into a cylinder. The tightness of the bale is preset and then measured as the bale wraps. Once the desired bale tightness is reached, the operator is notified and stops the baling.

The round bale is then wrapped with baler twine; the baler opens, and the round bale is ejected. This wrapping and compression effectively seal the inner layers, almost like a thatched roof. This helps the bale deflect water easily, so they are the more common type of bale to be left out in the field.

Rectangular/square hay balers

Square hay balers pick up the hay from the field, rake it, feed it into a framed and sized bale chamber, compress it, and cut it to the desired size. There are different size options, from 4 ft (1.2 m) bales to 7 ft (2.1 m) or 8 ft (2.4 m) bales. Bale sizes will depend on the type of grass harvested, with straw and hay cut into bigger bales used for near-term animal feed and silage (or haylage) cut into smaller bales to be stored longer in a silo for winter feed.

The rectangular bale is compressed by moving the collected hay into the compression chamber with raking arms and an auger mechanism. Once the bale is complete, it is cut to the desired size, wrapped with baler twine, and either ejected or ‘kicked’ onto a hay rack towed behind.

Because rectangular bales stack neatly, like bricks, they are easy to load onto a trailer or truck and are regarded as very stable for transport. When stored in a barn, they stack easily for later use as feed, and can provide insulation and warmth for animals during the winter.

Silage balers

An additional type of hay baler to include is the silage baler. These baling machines use round or square baler mechanisms but are not towed by a tractor. Instead, they are set up in a fixed stationary location to be fed by a smaller conveyor belt.

The hay is necessarily left wet and may be treated with a bacterium so that the hay ferments and breaks down to be used later as animal feed. Either the wet hay is pitchforked manually onto the conveyor, or a hopper/feeder can be used to feed the silage onto the conveyor.

Silage balers will usually wrap the bale in plastic, both for easy transport and also so that the hay can ferment within the wrapping.

What to consider when selecting a hay baler

How can you review what’s available and choose the right baler for your needs?

Although balers are mechanically quite simple, there are a number of factors to consider when reviewing and selecting the right baler for the desired use,as well as the baler-tractor pairing. These specifications are not always readily available to the buyer, so the buyer may need to be ready with a checklist of questions to be able to get sufficient details to make a comparison.

Round or square baler?

Because round baler machines, which compress hay into a cylinder shape, work differently from square balers, which compress hay into a brick-like shape, a round baler cannot produce square bales, nor can a square baler produce round bales. Therefore, the choice is for one type of machine or another, and the choice is determined by the farmer’s intended purpose and use for those bales.

Hay baler or silage baler?

The farmer will know their needs and uses, and this will help answer questions about round or square balers, as well as whether the bales are to be plastic-wrapped or just bound. The operator will also have a clear idea of whether those wrapped bales are to be left in the field to ferment for silage or whether a silage baler is required instead of a towed baler.

Operating HP, RPM and bundles per hour

Baler specifications will usually include the operating speed in rotations per minute (RPM) and the minimum horsepower requirement to drive the baler (typically between 25 hp and 120 hp). Therefore, ensure that the tractor has sufficient PTO horsepower for the baler you have in mind. The specs should also show the baler’s maximum productivity in terms of bales per hour (bundles/h).

Tractor-baler connectivity

Also, as part of pairing the towed baler with a tractor, specifications will show what fittings are required, including towing connections, PTO connections, hydraulic towing angle, and pick-up height, as well as whether the baler has its own hydraulics.

Bale size and weight

The baler specifications should show the minimum and maximum setting sizes for the bale (bundle size), as well as the minimum and maximum bale weights (bundle weight).

Bale chamber size and pressure

Look for the size of the bale chamber (or press box) as well as the compression nominal force (usually expressed in tons).

Feed mechanism

Specifications usually show the feed opening size (L*W*H). The specifications for a silage baler will also show the conveyor width, length, and processing speed, usually in bags per hour (bag/h).

Examples of hay balers available online

Here is a sample of the many hay balers available for order online, showing a small selection of round hay balers, square hay balers, and silage balers.

This mini round hay baler has specifications that state a compression force of 1,600 tons and a bale chamber (press box L x W x H) of 7.2 x 3.7 x 4.3 ft (2,200 x 1,120 x 1,300 mm). The baler can produce a bale size of 3.7 x 3.6 x 3.6 ft (1,120 x 1,100 x 1,100 mm) with a bale weight of between 0.9 and 1.4 tons (adjustable). Prices range between US $750 and US $1,150, depending on the number of units ordered.

The supplier notes that this large round hay baler can be used for a variety of crops, including cotton, straw, wheat straw and corn. It has a pick up width of 7.2 ft (2,200 mm), and a compression chamber width of 4 ft (1,230 mm). It can produce bales up to 0.2 tons.

This baler suits tractors with more than 100 hp, and has a PTO speed of 540 rpm. Productivity is rated at over 12 tons per hour and this model’s cost is between US $1500 and US $2000.

This mini round hay baler has dimensions of 11 x 4.9 x 4.8 ft (3,400 x 1,500 x 1,460 mm) and a processing speed of 350 rpm. Bale sizes are 1.8 x 1.7 ft (550 x 520 mm), and the baler has a bale processing speed of 4 tons per hour. This model is available for US $750.

This model is a mini square hay baler, and specifications show that it has a working width of 1,440 mm and can produce 80–240 bales per hour with a PTO speed of 540 rpm. It has a minimum power requirement of 25 hp and connects with a two-stage PTO transmission. This model is offered at between US $8,500 and US $12,500.

This version of a square hay baler, shown here, has a working width of 800 mm. It requires a minimum of 18 hp from a connected tractor, up to 80 hp. When running, it can produce 80–120 bales an hour of sizes ranging from 1.6 x 2.3 ft (5,000 x 7,000 mm) to 2 x 2.3 ft (6,100 x 7,000 mm), with a maximum pulling speed of 2–4 mph. This square baler costs between US $5,300 and US $5,500.

This large-capacity square hay baler has an operating speed of 1,000 rpm. Its working width is 7.2 ft (2,200 mm) to produce bale sizes of 1.2 x 1.9 x 1.15 ft (380 x 570 x 350 mm), adjustable up to a height of 4.3 ft (1,300 mm). It is priced at US $11,000 per unit.

This silage baler can produce bales of 2.3 x 2.3 ft (700 mm x 700 mm) at an input conveyor speed of 50–65 bags per hour with a bundle rotation speed of 350 rpm. Prices are between US $3,980 and US $4,080.

This round bale silage baler, shown with an already wrapped round bale. has a throughput capacity of 1–1.5 tons per hour for hay and 50–60 bales per hour, with a bale weight of 20–25 kg. Specifications show a wrapping capacity of 2–6 layers per bale at a speed of 8 seconds per layer. Compression chamber dimensions are given as 3.6 x 1.3 x 2.6 ft (1,100 x 400 x 800 mm), and pricing is shown as US $3,347.50 to US $3,811.

The above model is a round baler for silage, shown with the bale wrapper in the process of wrapping a bale. Bale sizes are 1.8 x 1.7 ft (550 x 520 mm), and the baler has a processing speed of 30–60 bales per hour. This version is available for US $2,700 to US $3,200.

This model of square bale silage baler works differently from the round silage baler, using a compression method. It can turn out 100–120 bales per hour, taking 30 seconds per bale. It uses 2-cylinder hydraulic compression, customizable to 3 cylinders. This baler is available for US $4,000.

Final thoughts

This article has reviewed the types of balers available on the market and provided a number of examples. Farmers know what they want from a hay baler, so which type to buy will be a conscious choice. The two types of balers are round balers, which produce cylindrical bales, and square balers, which produce rectangular bales, with each having its own purpose. Balers can be tractor-towed, picking up hay as they are pulled through the field, or stationary balers, loaded by conveyor and used to bale and wrap silage bales.

There are a number of factors to consider when selecting a baler, and the potential buyer should review the specifications for each model of interest. For more information, check out the online showroom at Alibaba.com.