Rice harvesting can be a very intensive manual task for many in the developing world, but is a major industrial process in much of the developed world. Rice harvesting machines come in different sizes and power and can play a crucial role at all ends of the scale. This article looks at some of the top models available in the online market, and offers buyers essential tips to find the best models for a range of applications.

Table of Contents

The projected global market for rice harvesters

What are the main requirements of a rice harvester?

A selection of rice harvester models available

What to consider when selecting a rice harvester

Final thoughts

The projected global market for rice harvesters

Rice crops are grown across more than 120 countries throughout the world. 90% of the world’s production comes from Asia, with China and India being the largest producers at 52% of global production. Bangladesh, Indonesia, Vietnam, Japan and Southeast Asian countries contribute most of the additional 38% of Asian production. In South America, Brazil is the leading producer at almost 3% of the global rice crop, and in North America, the U.S. has a long history of rice growing, producing around 2% of global output.

Many developing countries have mountainous or hilly topography for growing rice, with many small plot farmers. They may find investment into mechanical rice harvesting, either impractical or unjustifiable, especially when compared to local labor costs. However, in more developed countries, rice farming is a major industry and automation is a necessary investment.

With a growing global population, there is increasing demand for higher rice and wheat production, encouraging a greater use of technology to maximize efficiency. The global market for combine harvesters, to harvest rice, wheat and soya bean, is projected to grow at a healthy compound annual growth rate (CAGR) of 4.5% from a value of US$ 52.74 million in 2024, to over US$ 62.8 million by 2028.

What are the main requirements of a rice harvester?

Rice is a cereal crop and, like other cereal crops, is a type of grass. Unlike other cereal crops, rice grows in a bed of water, submerged by between 2” to 4” (5-10 cm) in irrigated paddies, and the rice stays submerged in water throughout the growing season. In many parts of Asia, rice paddies are built down hills in a stepped manner, with mountainous areas such as the Himalayas being some of the most extreme growing landscapes.

The stepped and often steep rice growing landscape across much of Asia makes rice paddies impractical for large machines, so rice harvesting is usually manual and very labor intensive. However, in developed and industrialized regions, rice paddies are spread across wide open expanses of fields, and so harvesting can be more mechanized and rice harvesting machines can be used.

When it is time for harvesting, paddies are drained and the paddy fields dry out, although some will remain water-logged for harvesting. The water content of the rice grasses reduces to around 20-25% by harvest time, which means that the rice stalks are still quite wet when harvested.

When harvesting rice manually, the rice is first cut, or reaped, and stacked. The edible grain part of the rice is then manually separated from the straw by beating (threshing). After threshing, the rice will need to be cleaned to separate remaining straw, stones, and paddy. The rice is then dried until water content is down to around 14%, before milling to remove the husks, or before storing. Wet rice will not mill well, or will attract mold in storage.

When automating the rice harvesting process, the farmer may choose a reaping machine only, or choose a rice combine harvester. Rice harvesters are a type of combine harvester for harvesting rice rather than other cereal grains, although they may be able to handle multiple crops. The ‘combine’ functionality means they can reap, thresh, clean and winnow all in one pass.

They are often fitted with rubber tracks to handle wet paddy fields, and if the rice grass is too wet, the harvester may not use the winnowing function for separating rice and husk.

Rice harvesters are commonly diesel driven and range in power from around 10 hp to as much as 450 hp. Most lower priced models are mechanical only, but the latest and largest models use advanced sensor technology to maximize grain capture and minimize loss.

A selection of rice harvester models available

Mini combine harvesters

For many small family rice farms, especially in developing countries, the investment in technology is a big commitment compared to local labor. So for small plots, a small rice harvester with low capacity may be a suitable compromise between mechanization and manual work.

The smallest harvesters may reap and bind only, but are easily transportable. Other rice harvesters can reap and thresh the rice grasses, clean and separate the rice from the straw. They do not have a large capacity to hold much grain, so that is dispensed from an outlet to be gathered in sacks or other containers.

This simple harvester model reaps and binds the stalks, but does not thresh or clean the rice from the stalks. With only 8-12 hp and a cutting width of 3.2 ft (1m), it will reduce the manual effort of clearing the rice (or wheat) field, but leaves other tasks to manual labor. This model is a walk-behind, wheeled machine, and is available for between US$ 4,000 and US$ 4,500.

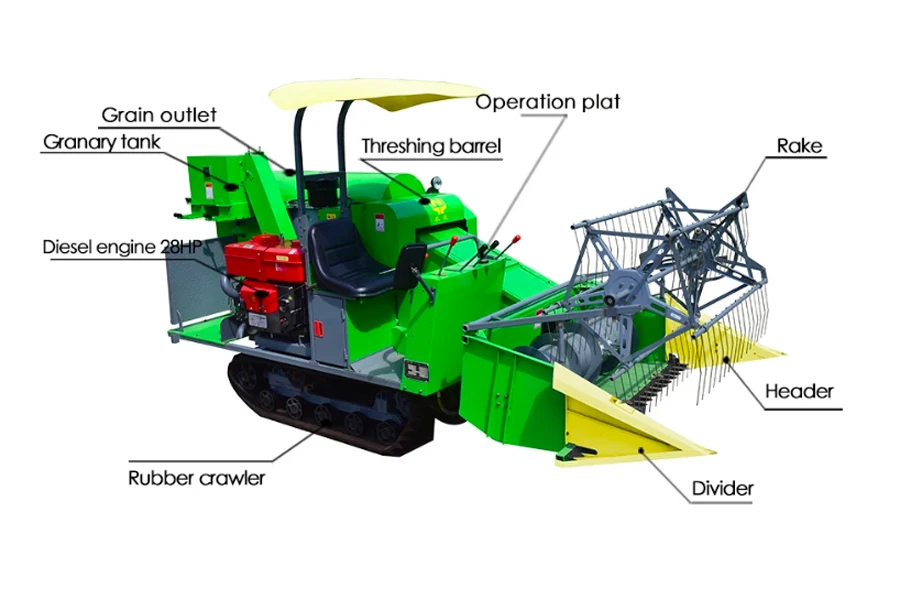

This small rubber tracked rice harvester has a working width of 4.6 ft (1.4m) working width, and is available for between US$ 4,500 and US$ 5,200 per unit. The rake and header feed the cut grasses up a conveyor into a thresher, and a vibrating cleaner separates the grain. Its rubber tracks handle wet and muddy fields well, and the machine is suitable for rice, soya bean and wheat crops.

This mini rice harvester has a working width of 3.9 ft (1.2m) and is priced at between US$ 4,580 and US$ 4,880. It has rubber tracks for easy wet paddy operation, a small control seat, and the harvester reaps, threshes, cleans and separates grain.

Small to mid-sized rice harvesters

As the size of the harvester increases in both power and working width, rice harvesters offer full combine harvester functionality of reaping, threshing, cleaning and winnowing. Of course, as harvesting capacity increases, so does price. Some of these models are fitted with rubber tracks, but others are fully wheeled models.

This Japanese Kubota brand rice harvester has a working width of 2m and maximum power of 120 hp. It has rubber tracks for wet terrain working and is advertised as suitable for rice and wheat. It offers a large threshing cylinder and three layers of vibrating screen for cleaning. Prices range for US$ 10,500 to US$ 11,500.

This rice harvester has more power at 52-76 hp and a wider working width of 7.2 ft (2.2m). It has rubber tracks for easy movement across wet paddies and full combine harvesting features. It has a loading hopper for separated rice grain to be loaded into a supporting transport vehicle. This model is available for between US$ 24,025 and US$ 24,425 depending on the number of units ordered.

This version of a rice and wheat combine harvester produces 88 hp, has a 6.6 ft (2m) working width, and a 1400 liter grain tank. This is a wheeled harvester and is available for between US$ 14,500 and US$ 15,800.

This rice harvester has a working width of 9.3 ft (2.84m) and a maximum power of 190 hp. It has full combine harvester functionality to handle rice, wheat and soya bean. It has a wheeled base and will have best traction in dry paddies and fields. Prices range from US$ 27,800 to US$ 29,800.

Large rice harvesters

In the U.S. and in other developed and industrialized nations, rice growing and harvesting looks very different from much of Asia. Although the method of growing rice is the same, the scale is markedly different, harvesting machines are larger, and higher technology methods are implemented.

The wheeled harvester shown here hard at work harvesting has a 10.4 ft (3.2m) working width and can be used for rice or wheat. As with other models of this size it comes with a wide-aspect comfortable operating cabin and full combine harvesting features, a wide grain store and hopper. This model is available for US$ 10,000.

This large size rice harvester is a wheeled model, but has attachable rubber tracks for wet field harvesting. It has a maximum power output of 450 hp and can handle rice and other crops. It also has an optional rear attachment for chopping and spreading straw.

As a larger machine, it comes with an enclosed comfortable driver cab, with a wide field of vision, and is fitted with both heat and air conditioning. This is one of the more advanced models and has monitors for GPS, grain loss, moisture content and yield. This harvester is available for US$ 8,599.

What to consider when selecting a rice harvester

When considering which would be the right rice harvester to buy, there are a few key factors to bear in mind.

Size and weight

The first consideration is the terrain and size of rice paddy. For most hilly environments, the paddies themselves are quite small as they are contoured to the land, but also they tend to have very limited access, perhaps limited to paths or small tracks. For these paddies, size and weight of the machine are the biggest factors, and the largest practical machines are likely to be the small walk-behind reapers.

For larger paddies with road access, then choices can be quite varied, because access is no longer the limiting consideration. Smaller fields will want to consider the mini rice harvesters, that are big enough and powerful enough to harvest the paddy, yet small and mobile enough to move between paddy fields.

For larger commercial rice farms, with large wide and flat acreage, the bigger rice and combine harvesters are a good choice.

Width of header

The amount of rice crop that the harvester can cut with each single pass is determined by the working width of the header. The size of paddy, and the rice crop layout, determine the harvesting capacity and header width. A narrow header may best suit a small paddy, but also means more passes up and down the paddy field. A wide header handles more crops in a single pass, so is likely to be the most efficient for large wide paddy fields

Wheels vs. rubber track

Rice paddies are usually drained before harvesting, but may still hold a lot of water and the ground may still be very soft when the time comes for harvesting. Wheeled harvesters do not make a wide contact with the ground and are prone to sink into the soft paddy soil, making smooth harvesting slow and difficult. However, if the ground has dried fully, wheeled versions are easy to steer and to move around. By contrast, the triangular rubber tracked harvesters spread weight across the tracks and do not sink in far, keeping mobility and harvesting pace. Therefore, consider carefully the likely climate and soil properties, and choose accordingly. If the harvester has interchangeable tracks and wheels, that may provide best flexibility.

Harvester power

The engine power determines the cutting power of the header, drives the threshing and cleaning functions, and powers any additional functions such as cutting and spreading. The harvester must be able to produce sufficient power for all functions, so check the rated horsepower, especially for mini harvesters.

Broad guidelines for power requirements for a rice harvester will vary by machine size, with mini harvesters producing between 10 to 30 Hp, and the larger models anything from 100 Hp upwards. Extra horsepower will get the job done, but too much power will waste fuel and increase cost. Amongst the more powerful diesel engine brands are Kubota and Cummins, although there are also powerful electric engine versions available for mini harvesters that produce upwards of 66 Kw / 88 Hp.

Budget, functionality and technology

Smaller machines can be purchased very cheaply, with the smallest lacking full combine harvesting features. Mini harvesters are a good option for small rice farms, as they typically have full combine harvester functionality and come at a modest price, but will likely not come with any high-tech features. Larger models and the top brands come with a larger investment, but many of these include advanced technology systems, including GPS systems, yield measuring, and thresher speed adjustment.

Final thoughts

There are plenty of harvesters available that are intended for use in rice paddies. Many of these models are also capable of handling wheat and other crops. Many farmers across Asia may prefer to stick with manual labor harvesting, but for those wanting mechanical help there are both simple and more advanced models.

At the lower end there are small walking harvesters that do little more than cutting, but from there most harvesters offer a full combine harvester functionality. These functions include reaping, threshing, cleaning and winnowing. Some can also add chopping and spreading of the unwanted straw.

Rice harvesting can often be wet and the ground soft, and many of the rice-specific harvesters are fitted with rubber tracks to be able to move more easily and not sink in. Also, where rice grass is harvested wet then the rice grain may need to be stored and dried before milling to separate the husk.

For the potential buyer, there is plenty of choice and a range of harvesters available to fit crop, functionality and budget. For more information, check out the online showroom at Alibaba.com.