A fuse is an electrical protection element used to prevent the overload or short circuit of a circuit from causing damage to other components. Whether it is mobile phones, computers, cars, and other electronic products, fuses needed to ensure security in a range of appliances.

This blog is aimed at assisting retailers to get an overview of the market for fuses, as well as providing key insights to ensure you can select the best options for a range of uses in 2024.

Table of Contents

Global fuse market overview

Understanding fuses

Common types of fuse components

Development trends of the fuse market

Selection suggestions

Conclusion

Global fuse market overview

According to DIResearch research statistics, major global fuse manufacturers include Littelfuse, Legrand, Mersen, Huade Electronics, Zhongrong Electric, Eaton, SCHURTER, Siemens, Power Electronics, ABB, Bel Fuse, Hollyland, Bette, AEM Technology, Dayi Technology.

The size of the global fuse market shows a steady expansion trend. The global fuse market sales reached CNY 22.66 billion in 2023 and are expected to reach CNY 36.23 billion in 2030, with a compound annual growth rate (CAGR) of 6.93% from 2023 to 2030.

From the perspective of product type and technology, the market size of consumer electronics plug-in fuses accounts for about 13.47% of the global market; consumer electronic patch fuses account for about 14.62%; and low-voltage fuses for industrial photovoltaic electric vehicles account for about 22.30%. The new energy market has become the main driver of future growth, and the photovoltaic and electric vehicle industries will become the main drivers of fuse growth in the future.

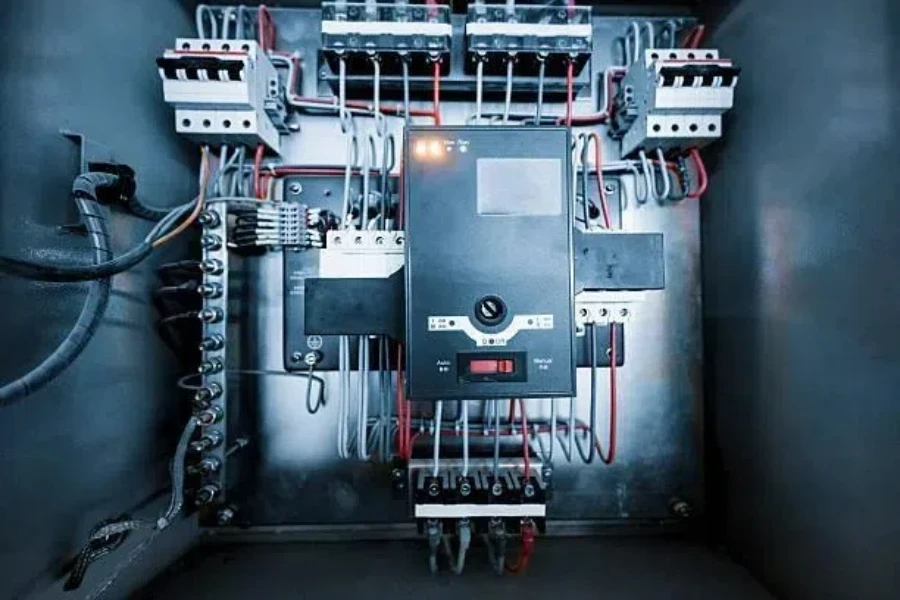

Understanding fuses

Using fuses helps mitigate the risk of hazardous events such as fire and electric shock, thereby providing protection for both individuals and equipment and contributing to overall safety improvement. When the current exceeds the fuse’s rated capacity, it serves as a critical line of defense by interrupting the circuit, thus preventing overcurrent damage and potential shock hazards. In order to understand more about how fuses work, the following are useful to pay attention to:

Rated voltage: The maximum voltage at which a fuse can operate safely. Common rated voltage values are 32 V, 60 V, 125 V, 250 V, 300 V, 500 V, and 600 V.

Current rating: The current rating of a fuse indicates its capacity to carry a specified current under normal operating conditions. This rating is clearly indicated on each fuse, often denoted by numerical values, alphanumeric characters, or color coding.

Breaking capacity: The breaking capacity of the fuse is the maximum current at which it can safely break at its rated voltage. The breaking capacity must equal or exceed the expected maximum fault current in the circuit.

Ambient temperature: Ambient temperature is the air temperature directly in contact with the fuse, not room temperature. The electrical characteristics of the fuse are rated at 25°C ambient temperature.

Surge and impulse current characteristics: Some applications generate surge currents and require fuses to be able to pass through these surges without misfiring or damaging the fuse element. The pulse current will generate heat energy, which may damage the fuse and affect its life.

Fast and slow fuses for different purposes: Fast fuses break quickly in the case of overload or short circuits, disconnecting within 5 seconds at 200% to 250% of the rated current, in line with UL standards. In contrast, slow fuses allow temporary surge currents to pass harmlessly, disconnecting within 2 minutes during a sustained overload or short circuit, in compliance with UL standards.

Safety standards and certificates: IEC and CE are common options to look out for to ensure a quality product.

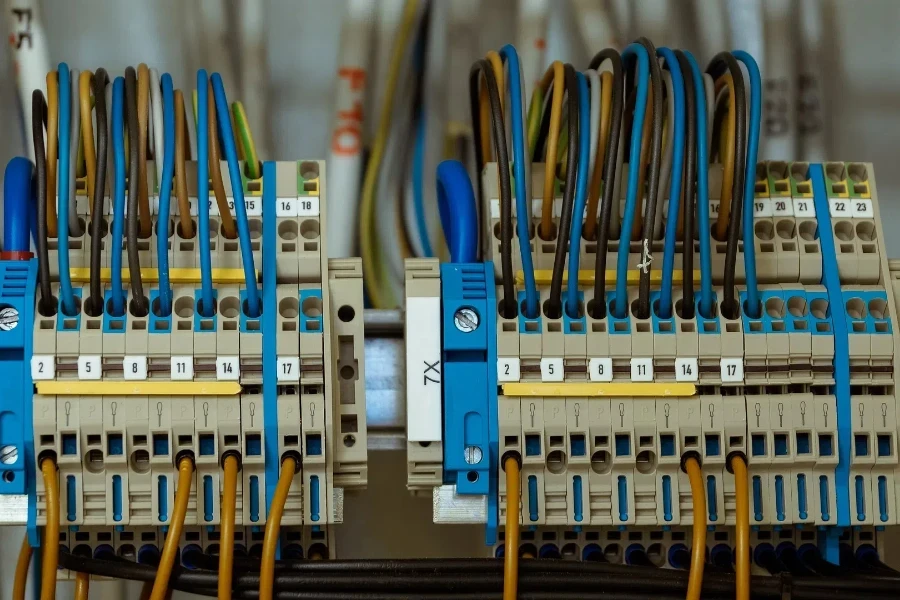

Common types of fuse components

Fuses play a crucial role in safeguarding electrical equipment, and their classification is both diverse and intricate. Initially, they can be broadly categorized based on their intended application scenarios. After this, their precise selection hinges on meeting specific requirements regarding fundamental parameters.

Power fuse

These are mainly used in domestic, commercial, and industrial electrical systems. These fuses are usually designed to withstand higher currents to protect the circuit from overload and short-circuit damage. They are generally larger in size to accommodate the needs of high-power equipment.

Machine tool fuse

These fuses are specifically designed to protect the circuitry of machine tools and industrial equipment. They may be specially designed to accommodate vibration and shock in the machine’s operating environment.

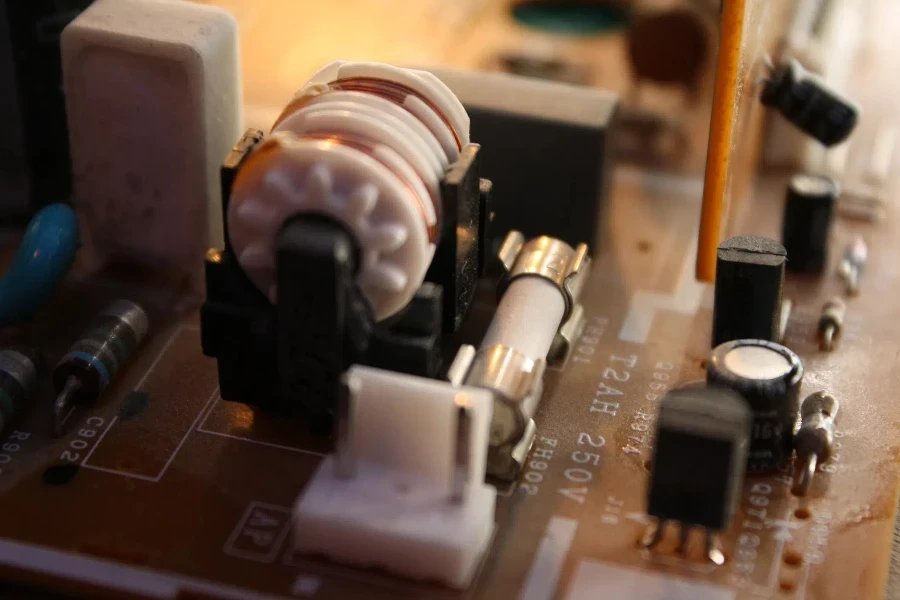

Electrical instrument fuse (electronic fuse)

Electrical instrument fuses are commonly used in electronic devices and instruments, such as televisions, sound systems, computers, etc. They are typically more finely designed to accommodate the needs of low-power electronics and are often able to disconnect the circuit faster to protect the device.

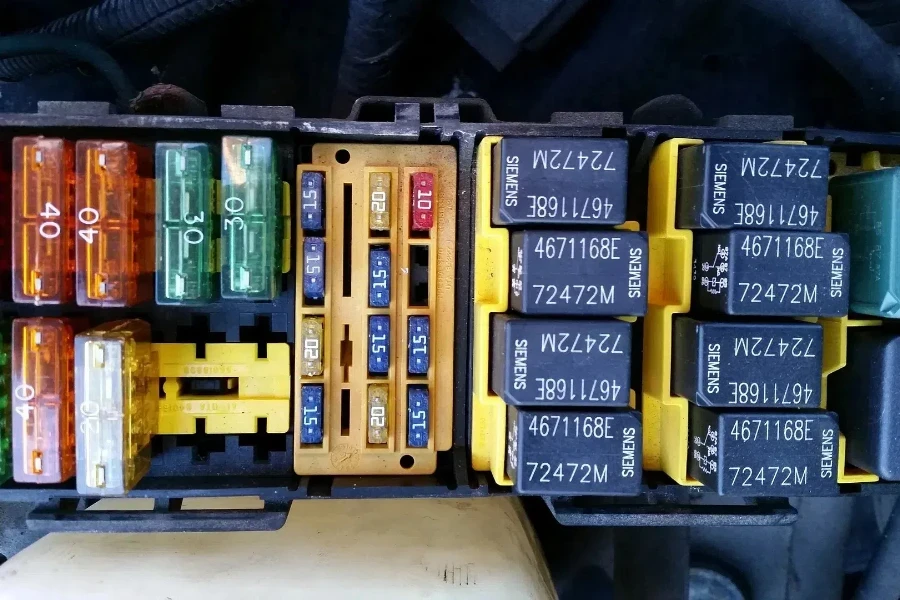

Automobile fuse

Automobile fuses are used in automotive electrical systems to protect vehicle circuits from overload and short-circuit damage. They usually have characteristics such as water, dust, and oil resistance to adapt to the requirements of the automotive working environment. The current rating and operating characteristics of automotive fuses usually vary according to the vehicle’s design and the manufacturer’s requirements.

Development trends of the fuse market

Benefitting from advancements in new energy vehicles, photovoltaic and wind power generation, communications, rail transit, and digital technology, the fuse market is experiencing rapid growth in demand.

As application circuits diversify, customers increasingly seek personalized fuse performance, driving the integration of intelligent functionalities into fuses. Speculations suggest that future fuses will embody intelligence and modularity, catering to evolving market needs.

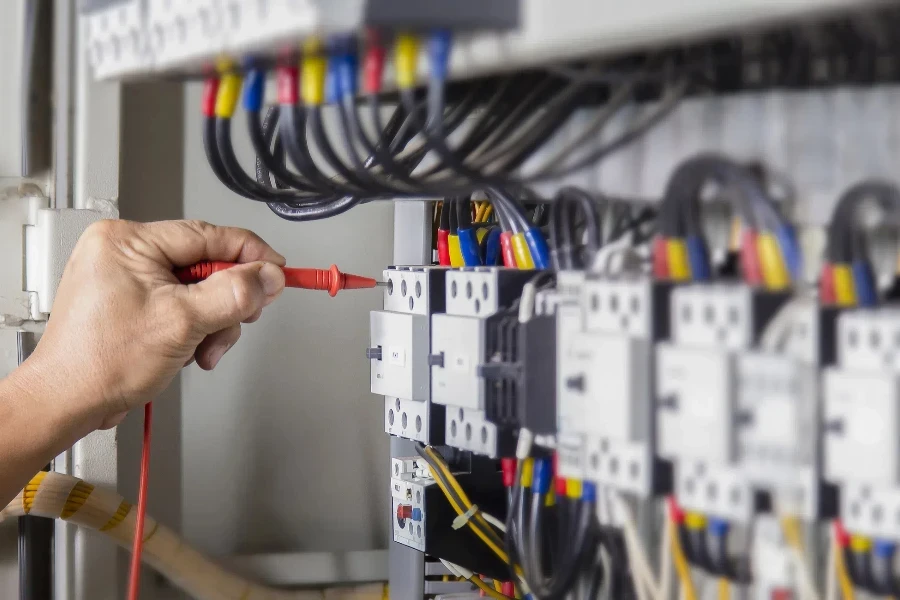

Selection suggestions

Fuse component expertise and selection skills are the basis for ensuring the safety and reliability of electrical equipment. This section will help you understand the importance and complexity of fuse components so that you can make more informed purchasing decisions.

Rated current (In)

The rated operating current of a fuse is marked as In. It is the current that can be carried by the fuse. The rated current must be greater than the actual operating current of the protected circuit, taking into account the derating specified in international standards.

- IEC Regulations: No Derating (CE certified)

- UL Regulations: 0.75 Derating (UL certified)

In most cases, 0.75 derating is considered. For the operating current of a board, pay attention to the current at the lowest allowable voltage. For example, the rated voltage is -48 V, allowing 20% fluctuation (A fluctuation range of ±10% is allowed for 12 V voltage or less.) If the board’s operating current is 0.8 A at -48 V, since the board’s power is constant, the operating current at -38.4 V is approximately 1 A. In this case, 1 A should be considered the operating current of the board during fuse selection.

Notes:

- For loads such as fans with motors, the operating current is determined according to the maximum average current in the fan specification.

- If two fuses are used in parallel, the circuit operating current of the fuses is relatively larger. In this scenario, if a fuse is selected in accordance with the above principles, the difference between the rated current and the actual working current of the fuse may be too large, and there are potential risks. In this case, you are advised to select a fuse based on 0.85 derating. For example, if the total operating current is 40 A, that of a single channel is 20 A. The rated current should be 23.5 (20/0.85), and fuses with 25 A rated operating current can be selected. The two channels add up to 50 A.

Rated voltage (Un)

The rated voltage marked on a fuse is code-named Un, which represents the maximum operating voltage circuit at which the wire can be used. A fuse can be used in a circuit that is not greater than its rated voltage. Derating does not need to be considered for the rated voltage.

Common voltage rating of fuses includes 32 V, 63 V, 125 V, 250 V, 300 V, 500 V, and 600 V. For example, 32 V or 63 V fuses can be selected for 12 V or 24 V equipment; for 48 V or 60 V equipment, 63 V and 125 V fuses are available; 125 V and 250 V fuses are available for 100 V or 220 V equipment.

Some fuses are marked with AC or DC-rated voltage. In principle, AC fuses and DC fuses cannot be mixed, and fuses marked with DC-rated voltage are only for DC circuits. Some fuses that have both AC and DC marks or do not distinguish between AC and DC can be universal.

Note:

For circuits with low voltage, such as 3.3 V or 5 V, avoid using fuses to avoid the voltage drop or even load undervoltage caused by fuses. If you must use fuses, calculate the pressure drop carefully.

Conclusion

Fuses silently protect our everyday electronics from a range of threats. Understanding this essential component is paramount for both electrical appliances and personal safety.

By delving into the basics, common types, latest trends, and market dynamics of fuses, this guide aims to assist in making informed purchasing decisions to ensure you are stocking the best of what the market has to offer.

To browse a range of quality fuses for different end uses head to Alibaba.com.