Table of Contents

● Introduction

● Market overview

● Key technology used in stabilizers

● Top-selling models driving market trends

● Conclusion

Introduction

Voltage stabilizers are crucial in ensuring the consistent performance and longevity of electrical appliances by protecting them from voltage fluctuations and power surges. These devices are vital across various industries, safeguarding equipment from potential damage caused by unstable power supply. Innovative features such as intelligent control systems and enhanced safety mechanisms are making these devices more reliable and efficient. Understanding the market dynamics and the technologies behind top-selling models provides valuable insights for businesses in the consumer electronics industry.

Market overview

The global electronic voltage stabilizer market is projected to grow significantly, reaching $8,884.5 million by 2032 with a compound annual growth rate (CAGR) of 4.8%. This growth is driven by increasing demand for stabilizers in various applications, including industrial, medical, home, commercial, and public utilities.

Key regions contributing to this growth include North America, Europe, and Asia-Pacific, with China playing a pivotal role in the market dynamics due to its large manufacturing base and rising consumption of electronic devices.

Technological advancements and innovation are also central to this market growth, with companies investing in research and development to enhance the performance, efficiency, and reliability of voltage stabilizers.

Key technology used in stabilizers

Electromechanical and static stabilizers

Electromechanical stabilizers, utilize mechanical components such as motors and variacs to adjust the output voltage. They have a slower correction speed, typically around 10 to 50 milliseconds per volt, making them suitable for applications where voltage fluctuations are gradual.

In contrast, static stabilizers employ solid-state electronic components, such as thyristors or IGBT (Insulated Gate Bipolar Transistors), to correct voltage fluctuations with speeds as fast as 2 to 4 milliseconds per volt. This rapid response is crucial for protecting sensitive electronic equipment like computers and medical devices.

Voltage stabilizers with advanced components

Modern voltage stabilizers incorporate advanced components to enhance their performance and reliability. Key elements include variable transformers and buck-boost transformers, which adjust voltage levels dynamically. The control systems in these stabilizers are often based on microprocessor technology, providing precise regulation by continuously sampling the output voltage and making real-time adjustments.

The use of high-efficiency motors ensures smooth and accurate voltage corrections, maintaining stability even under fluctuating load conditions. Additionally, these stabilizers can handle overload conditions by sustaining up to twice the rated current for short periods, ensuring the safety and continuity of operations.

Technological advancements

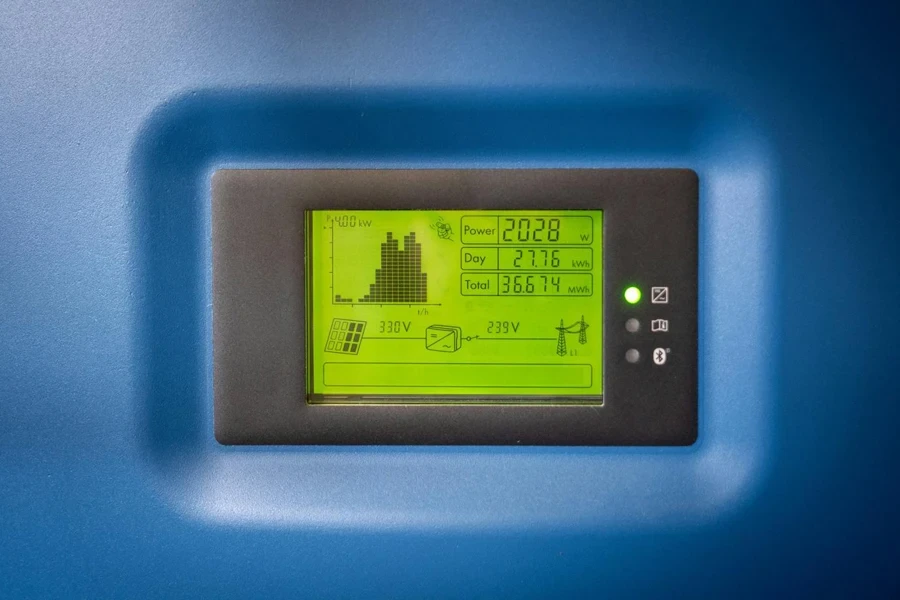

Recent advancements in voltage stabilizer technology focus on improving efficiency and user convenience. Intelligent control systems now feature digital displays for real-time voltage monitoring, providing users with immediate feedback on performance. Advanced models include protection mechanisms such as thermal overload protection, which automatically disconnects the stabilizer in case of excessive heat, and initial time delay systems that protect equipment during startup.

These stabilizers also employ EMI filters to suppress electromagnetic interference, ensuring that connected devices operate without disruptions. Some high-end models use adaptive algorithms to optimize voltage regulation based on load characteristics, further enhancing their efficiency and effectiveness.

Design and functionality

Selecting the right voltage stabilizer involves considering several technical factors. The number of phases (single-phase or three-phase) should match the load requirements. The rated voltage must align with the nominal voltage of the connected equipment, and the stabilizer should accommodate the expected range of input voltage variations. For instance, a stabilizer designed for a ±20% input variation range will maintain stable output even if the input voltage fluctuates significantly.

The type of regulation (independent or balanced) depends on the specific application needs. Independent regulation on each phase is essential for three-phase systems to prevent voltage imbalances. Additionally, the installation environment, such as indoor or outdoor settings, and specific conditions like ambient temperature and exposure to chemicals, influence the choice of stabilizer. High-end stabilizers are built to operate efficiently in harsh environments, featuring robust construction and high ingress protection ratings.

Selling factors driving market trends

Performance and reliability

Top-selling voltage stabilizers are recognized for their high output voltage stability and robust construction. These models incorporate advanced technologies such as automatic voltage regulators (AVRs) and digital signal processors (DSPs) to maintain precise voltage levels. For example, the V-Guard VG 400 stabilizer uses a sophisticated microcontroller-based design to ensure a stable output voltage within a ±1% range.

The use of high-grade silicon steel in the core of transformers and heavy-duty copper windings enhances the durability and performance of these stabilizers, ensuring they can handle continuous operation in demanding environments.

Safety features

Leading models feature multiple safety mechanisms to protect both the stabilizer and connected equipment. Thermal overload protection is a key feature that prevents overheating by disconnecting the load when temperatures exceed safe limits. Initial time delay systems ensure that power is supplied gradually to sensitive equipment, avoiding sudden voltage surges.

Voltage cut-off mechanisms are integrated to disconnect the load during extreme voltage conditions, safeguarding devices from potential damage. For instance, the Microtek EM4160 stabilizer incorporates these features, offering high and low voltage cut-off, thermal overload protection, and a time delay system, ensuring comprehensive safety for connected appliances.

Energy efficiency

Energy efficiency is a critical aspect of modern voltage stabilizers. These devices employ power factor correction (PFC) techniques to minimize energy losses and improve overall efficiency. High-efficiency toroidal transformers, used in models like the V-Guard iD4 Ace 5540, offer superior energy performance by reducing core losses and enhancing magnetic coupling.

Additionally, stabilizers with intelligent control algorithms can adapt to varying load conditions, optimizing energy consumption and reducing operational costs. These features make them ideal for environments where energy efficiency is paramount, such as data centers and industrial facilities.

User convenience

User-friendly features are a significant factor in the popularity of top-selling voltage stabilizers. Digital displays are commonly integrated into these models, providing real-time monitoring of input and output voltages, frequency, and load conditions. Intelligent control systems enable automatic voltage regulation and self-diagnostics, reducing the need for manual adjustments.

Models like the V-Guard VG 500 come with advanced digital interfaces and remote monitoring capabilities, allowing users to manage and monitor their stabilizers from a distance. These conveniences ensure that users can easily maintain optimal performance and quickly address any issues that arise.

Conclusion

Voltage stabilizers are indispensable in both residential and industrial settings, ensuring the safe and efficient operation of electrical appliances amidst fluctuating power conditions. By incorporating advanced technologies, robust construction, and comprehensive safety features, these devices protect sensitive equipment from voltage fluctuations and surges. Their energy-efficient designs and user-friendly interfaces further enhance their value, making them a critical component in maintaining reliable and efficient power systems across various applications.