The many different types of boilers available in the market make it hard for buyers to find the ideal one. This article will focus on the top tips you need to consider before acquiring a boiler machine, the market share of the boilers, their demand, and the expected growth rate. It will also talk about the different types of boiler machines available, as well as their pros and cons. So read to ensure you can choose your next boiler with confidence.

Table of Contents

Demand and market share of boiler machines

Top five tips for purchasing the best boiler machines

Types of boiler machines

Conclusion

Demand and market share of boiler machines

In 2020, the market size for gas fire boiler machines in the industry was valued at US $2.7 billion. Future predictions indicate this market to grow at a compound annual growth rate (CAGR) of more than 4.5% until 2028. In fact, the U.S market for fire boilers is projected to reach no less than US $2.6 billion by 2028.

According to a 2022 report by Future Market insights, the overall global market value for residential boiler machines is US $29.5 billion. So at the growth rate of 5.4% CAGR for the next decade, this market size is expected to grow to US $49.9 billion.

Top five tips for purchasing the best boiler machine

1. Capacity of the boiler machine

Power Output of boilers can either be expressed in pounds of steam delivered in an hour or Boiler horsepower (MBTU). Generally, the steam a boiler produces usually varies with pressure and temperature. A standard unit for expressing this is BTU.

Depending on the amount of, say, hot water usage target, sizing a boiler machine for a room is a critical aspect. System and preheat boiler machines usually heat water to be stored in adequately insulated tanks. In such scenarios, the flow rate isn’t usually that critical.

Overall, average rooms have a heat load ranging from 34,000BTU – 68,000BTU. That means even conventional boilers can be sized much smaller than combi boilers. Note that boilers have different horsepower measured in BPH. So, a boiler with a horsepower of 30 BPH has a power output of about 1, 004, 000 BTU, while 6BPH represents about 200, 800 BTU. The higher the hose power, the better the performance.

Typically, cold climate weather requires a 50 BTU/sq.ft and 35 BTU/sq.ft boiler room for a moderate climate. However, hot weather temperatures require boiler rooms with 20 BTU/sq.ft.

2. Efficiency of the boiler machine

The more efficient a boiler machine is, the less amount of fuel it’s likely to consume. Basically, this refers to the fuel-to-water or fuel-to-steam efficiency. Modern boilers have up to 94 % efficiency, meaning that such boilers only lose 6% of the energy that goes into running them.

Annual fuel utilization efficiency (AFUE) is an important aspect when purchasing a boiler. This refers to the thermal efficiency measure of the boiler’s space heating. The higher the AFUE, the more efficient the Boiler machine. For instance, a 90% AFUE boiler will output 90 BTUS for 100BTUS of gas input.

Generally, boilers fall into two main categories, with the main one being for steam and water. To maximize a boiler’s efficiency, its turn down or the controllability ratio should allow for wide fluctuations in a building’s heating load. The boiler should match the building’s heating requirements for maximum efficiency.

3. Venting requirements for the boiler

Boilers need adequate housing with enough oxygen supply to ensure sufficient airflow. Modern boiler machines are room sealed, with the combustion chambers entirely sealed away. Such a room is usually ventilated through a flue pipe.

Tight spaces, such as cupboards, should also have temperature regulation measures, with ventilation being an important aspect. In such scenarios, the cupboard has an open door with a 300mm space at the top. This gap represents the space between the top of the cupboard and the top of the boiler. Moreover, there should be 100 mm space below the cupboard. One wall and the cupboard front should have a 700mm gap.

4. Available space

Space set aside for installing a boiler depends on the type of boiler machine itself. And since boilers come in various sizes, it’s advisable to review the available space in question. Notably, wall boilers are ideal for smaller spaces, while larger rooms can comfortably accommodate floor boilers.

Wall boilers are compact, silent, and lightweight. This makes their installation suitable for kitchen and bathroom spaces. When mounting the boiler to the wall, ensure first that there is natural light in the room. Also, the supply ventilation should efficiently ensure that the air changes within the room 3 times per hour.

Boilers such as combi, system, and regular boilers can be easily installed on the floor in a large room. The floor should be made of non-combustible materials. What’s even better is if the floor can be lined with concrete bricks. And the height should be at least 100mm. Additionally, the gas chimney hole and the boiler must match up for maximum efficiency and performance.

5. Power source

For a typical boiler to function efficiently, it needs a stable power source. More importantly, its power consumption should match the building’s heating load. Alternatively, you can install an economizer on your boiler regardless if it’s a fire tube or a water tube machine. Basically, an economizer reduces temperature up to 270 Fahrenheit. Reducing temperature past the 270F mark may cause the flue gas to condense significantly. A tip to regulate the flue gas temperature is to control the feedwater flow rate.

Different types of boilers

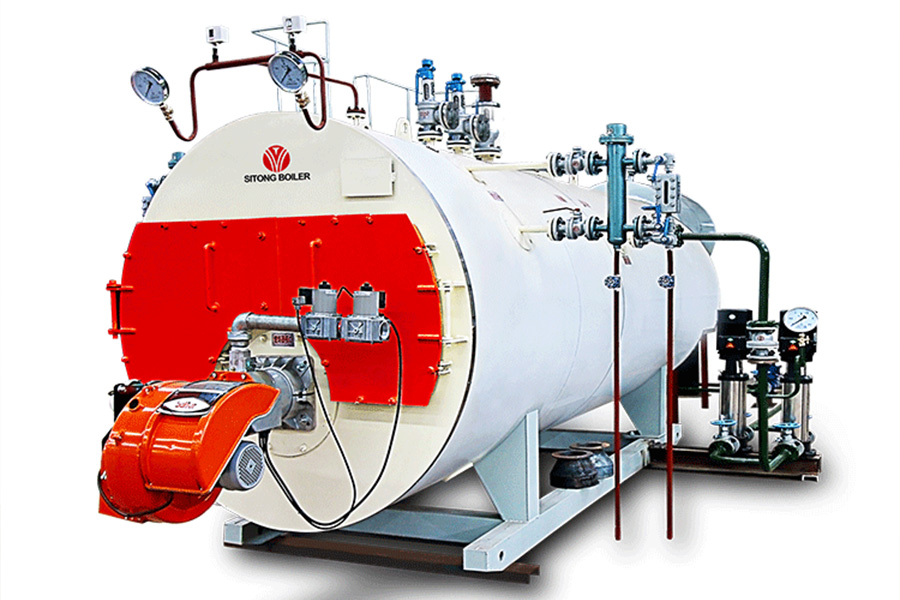

Fire tube and water tube boilers are the two primary boiler designs. Functionality-wise these two machines differ: for instance, fire tubes are used for hot water and steam, while water tube boilers are used primarily for generating steam. More on these boiler machines is outlined below.

1. Fire tube boilers

Fire tube boilers, also known as shell boilers, work by passing the hot combustion gasses their burner produces through a pressurized cylindrical compartment containing small tubes. The water is heated with the heat energy from the pressurized compartment until it turns into steam.

Generally, fire tube boilers are an excellent alternative for those who can’t afford water tube boilers. One of its major selling points is that it has a simple, compact, small design, plus it’s relatively easy to operate as it doesn’t require sophisticated skills.

Pros

- Requires fewer skills for efficient operation

- For similar output, fire tube boilers cost less than water tubesSimple design and cost-effective maintenance

- Feed water treatment is unnecessary

Cons

- Load fluctuations aren’t easy to handle

2. Water tube boilers

In terms of characteristics, water tube boilers vary a lot. For example, shell water boilers circulate water inside the tubes, with the heat source surrounding the tubes. In power stations, common water tubes have the following specifications:

- Up to 160 bar of high-pressure steam

- Extremely hot steam of up to 550°C

- Steam output of up to 500kg/s

Like package shell boilers, small water tube boilers can be made and completely assembled into a single functional unit, whereas larger units are assembled on-site with various parts making up the entire unit. Generally, most water tube boiler machines operate on the principle of thermosiphon, commonly known as natural water circulation.

Pros

- Requires less floor space

- Has efficiency of up to 90%

- It has sustainable power generation

- It has a well-defined water circulation direction

- Up to 250 bar maximum working pressure

- Suitable for large-scale industrial use.

Cons

- Requires skilled operation

Conclusion

Choosing the correct boiler depends largely on the application, type, and performance. Those seeking to make hydronic heating system upgrades in their rooms should consider Bosch condensing boilers. Due to the machine’s energy efficiency, it incurs significantly low monthly costs. Notably, a combi boiler system is a typical example of an energy-efficient system that’ll ensure a constant supply of hot water and heat in the house. For more, you can visit Alibaba.com to browse some of the best boilers up for sale.