Wrapping is an essential part of any business that has physical products. One method is shrink wrapping, which uses a clinging transparent plastic that shrinks tightly on the product. Wrapping is essential as it guarantees the safety of the product.

While many companies use human labor to wrap their products, wrapping machines are advisable, especially for companies with high levels of production.

This guide will offer a brief overview on the market for wrapping machines, before highlighting some key factors to consider when selecting wrapping machines for business.

Table of Contents

Market share

Why purchase wrapping machines

How to select a wrapping machine for business

Types of wrapping machines

Final thoughts

Market share

Globally, the wrapping machine market size was estimated at USD 2.5 billion in 2018. The food industry is one of the significant contributors to the wrapping machine market. This is due to the growing food and beverage industry. In 2018, the US had the largest market share for wrapping machines. It is estimated that the shrink-wrapping machine industry will report a compound annual growth rate (CAGR) of 13.8% from 2019 to 2025.

Why purchase wrapping machines

There are different reasons why businesses purchase wrapping machines. They include:

Protection

Wrapping products ensures their security from when they are packed to when they reach the client. This increases the chance that they will arrive safely and in good condition if transported via ships, trucks, or air.

Cost-efficiency

Shrink wrapping is a cost-effective way to pack products compared to other methods. Thus it is a preferable method for businesses. On top of that, the fact that it ensures the protection of the products saves the cost of reproducing and re-transporting them to the client should the products be damaged.

Convenience

Wrapping products with shrink wrap is easier than other methods of packaging because the wrap can fit the products despite their shape or size.

Display

Businesses can put products that have been shrink-wrapped on their display stand, killing two birds with one stone.

How to select wrapping machines for business

Different factors should be put into consideration when choosing a wrapping machine. They are:

Volume of products

Businesses should use the volume of products as a factor when choosing a wrapping machine. As such, the smaller the volume of products, the smaller the wrapping machine, while the opposite is also true.

Type of products

Some products are very delicate, while others are sturdy. Delicate products require a wrapping machine that will not damage them, while the sturdy ones will need a machine that can wrap them properly. Consider also the products being transported, and whether some may have odd shapes that need a special type of machine.

Budget for packing machines

Wrapping machines are not cheap. This means that the business’s budget is an essential factor to consider. Research is necessary, and analysis by a professional who can offer the best suggestion based on the business’s budget.

Machine automation

The degree of automation of the machine to be purchased should also be considered. Whether it is manual, semi-automatic, or automatic is an essential factor. Manual requires an employee around at all times, and semi-automatic requires an employee to pick wrapped products and place the unwrapped ones. In contrast, the fully automatic equipment wraps the products automatically from start to finish.

Type of production

Another factor to consider when buying a wrapping machine is the type of production. For example, is the production seasonal, time-based, or continuous? The answer to this question will help one to select the right machine.

The volume of wrap used

If wrapping a product uses a large quantity of wrapping paper, it is crucial to have a machine that can hold that whole amount of wrapping paper at once. Otherwise, the wrapping process can end up being a major headache.

Type of shrink film

It is essential to understand the type of film used. Some machines are not compatible with shrink wraps, and such information is vital when purchasing the wrapping machine. While some shrink wraps can be used to package both edible and non-edible products, others are used explicitly for packaging boxes, CDs, DVDs, and software, while others can package large commercial products.

Packaging capacity

The capacity of the wrapping machine is important because it determines if you can reach the full production target. If the machine doesn’t have the packaging capacity, then the production capacity will be delayed. If it has the packaging capacity, then it can hit the set targets and even more.

Types of wrapping machines

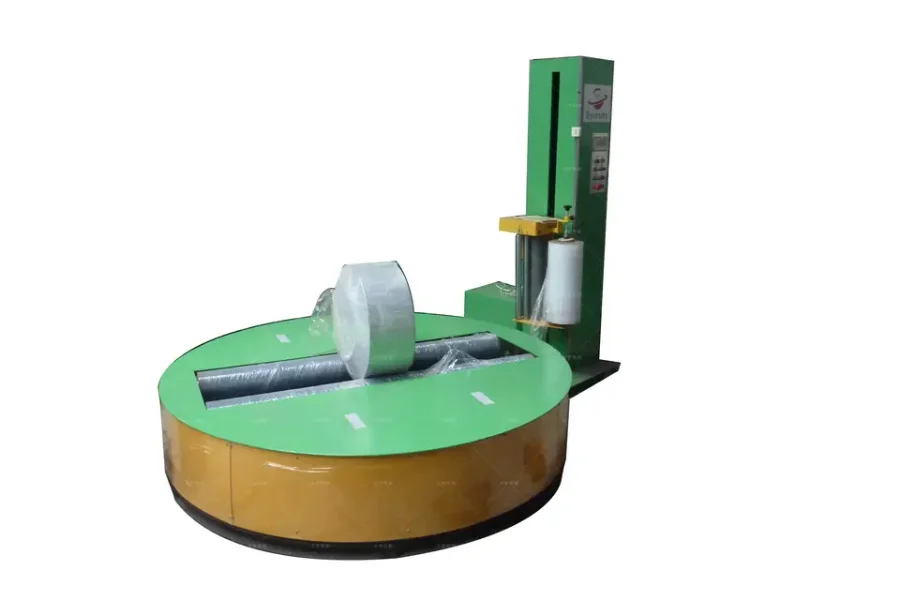

Turntable wrapper

The turntable wrapper machine’s pallet is a turntable that spins as a wrap system allocates the stretch wrap to the product that is being wrapped. The wrap delivery system begins wrapping from the bottom to the top and then to the bottom again. It is a commonly used wrapping machine.

Smart ring type wrapper

When wrapping with the straddle wrapping machine, the machine holds the product firmly as the wrap system spins around it, wrapping it. It is an effective machine when wrapping light unstable products and heavier loads.

Horizontal orbital wrapper

Also known as the ringer, the horizontal orbital wrapping machine wraps the product by going over it and under it while it goes on a conveyor into the machine. This machine is used when wrapping odd-shaped machines such as pipes and flattened packages.

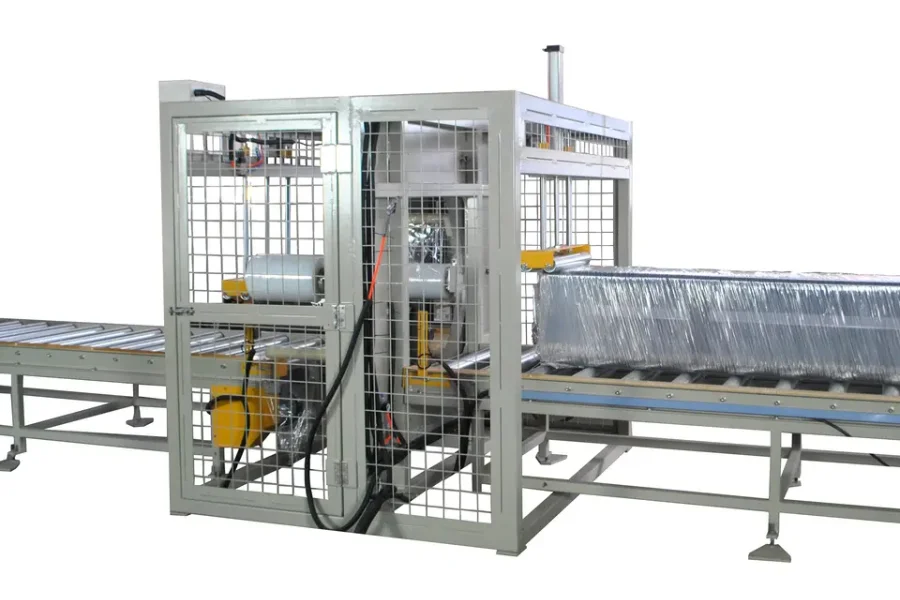

Horizontal automatic film stretch wrapping machine

The horizontal automatic film stretch wrapping machines are fast wrappers that can wrap up to 200 loads an hour. They are hybrid wrappers with both orbital and straddle features. Thus, while the product moves to and fro on the conveyor belt, the system wraps it in a motion similar to the straddle wrapper.

Final thoughts

There are different types of machines used for wrapping, and businesses need to navigate these various options to find the ideal machine that can match their production goals and protect their products. With the above information, businesses will be able to consider the essential factors that can help them choose the right machine. Visit Alibaba.com to learn more and browse a wide variety of wrapping machines to available.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu