Selecting the right spot welder is essential for a successful welding business. Spot welders are designed to join two or more metal parts together in one spot using heat and pressure.

However, choosing the right spot welder can be challenging. As a result, this article will cover the available types and factors to consider when purchasing a spot welder machine. With this guide, businesses can make an informed decision and find the spot welder that works best for different applications.

Table of Contents

Global market overview of spot welders

Selection tips for spot welders

Types of spot welders

Conclusion

Global market overview of spot welders

The global market for spot welders was worth US$ 2.53 billion in 2018, and the figure is expected to reach US$ 27.22 billion in 2030, growing at a CAGR of 7.6%.

The main drivers for the growth trend erupt from the need for solutions that increase the productivity rate in industries.

More reasons leading to a vast market size are the increased use of machines to weld safely and technological advancement.

Selection tips for spot welders

Welding thickness

When choosing a spot welder, considering the welding thickness is essential. Checking the welder’s specifications helps understand if it is more suitable for thin or thick metals.

The welding thickness influences the amount of current, voltage, and time the spot welder will require to weld the two pieces together correctly. A spot welder with little output suits welding together thin metals, while a spot welder with too much output suits welding thicker metals.

Users should therefore be careful and only acquire a spot welder compatible with the thickness of the metal they are welding. Choosing an incompatible welder may make poor-quality weld arcs or damage the metal material.

Power output

A spot welder’s power output determines the thickness of the materials it can weld. Higher power output will allow for the welding of thicker materials, whereas lower power output will only allow for the welding of thinner materials.

It is also essential to consider the types of materials being welded, as some materials may require higher power output than others. Additionally, higher power output can help ensure a high-quality weld and reduce the risk of faulty welds. Picking a spot welder with the appropriate power output is essential to help consumers achieve quality welds.

Temperature range

When selecting a welder, it is essential to consider the temperature range for the type of metals to weld. For example, a welder with a higher temperature range is necessary to weld strong metals like titanium. In contrast, a welder with a lower temperature range is suitable for welding softer metals such as stainless steel. Moreover, users should also consider the metals’ size and shape to ensure that the heat is evenly distributed when welding.

Power source

The type of power source used dictates the size and capacity of the spot welding machine to buy. A machine powered by a high-amperage power source will have a stronger welding current and thus a higher capacity for welding thicker materials. On the other hand, a machine powered by a low-amperage power source will have a lower welding current and may not be effective for welding thicker materials.

The power source also impacts the size and weight of the machine. For example, a machine powered by a significant power source will be bulkier, while a machine with a minor power source will be more compact. The type of power source will also determine the cost of the machine and its maintenance. Spot welders consuming high power have higher initial and maintenance costs than machines with a low-amperage power source.

Control options

When purchasing a spot welder, there are a few control options to consider. First, determine whether the users need a manual, semi-automatic, or automatic spot welder. Manual spot welders require the user to manually initiate the welding process, while semi-automatic and automatic welders are programmable to weld without direct user input.

Then, consider the type of control interface. Manual welders typically have a toggle switch or push button while semi-automatic and automatic welders may use a foot pedal, a digital display, or a programmable controller.

Buyers should check whether the welder offers current and voltage control features. Spot welders are purchasable with preset current and voltage settings or adjustable settings so the user can modify the current and voltage as needed.

The safety feature controls of the welder are crucial. Good spot welders will have various safety features, such as thermal cut-off, low voltage protection, and overload protection. All these factors make it easy to find a spot welder with reliable services.

Applicable material

When shopping for a spot welder, it is essential to consider the relevant material before purchasing. Different spot welders are designed to work with different materials, and selecting the wrong type of welder could result in reduced quality of the welded joint and even complete failure. For example, a spot welder for mild steel is unsuitable for welding silver or magnesium.

Types of spot welders

Resistance butt/upset welding machine

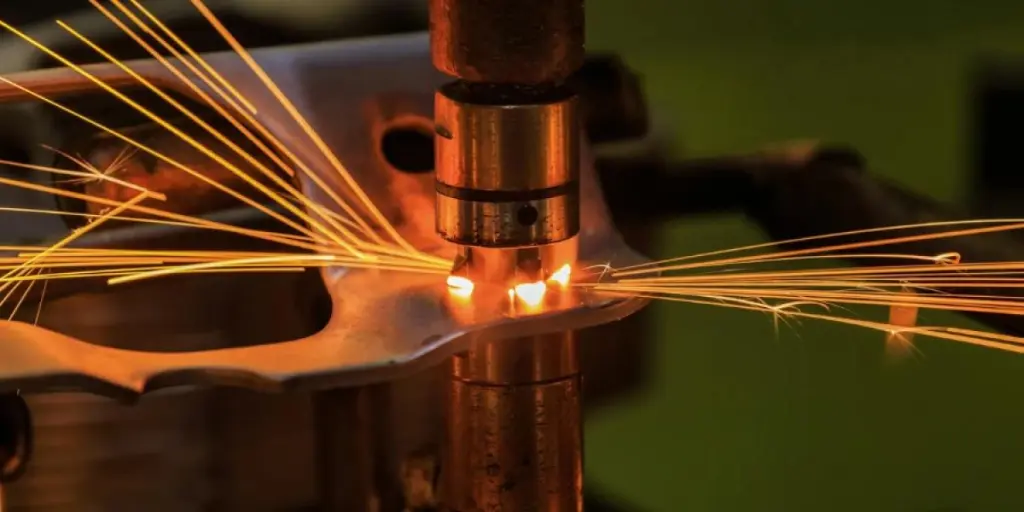

Resistance butt welders use a slow welding process that involves running a continuous current between the two pieces of metal for an extended period. The machine is often used for welding thicker pieces of metal when a high degree of strength is desired.

Pros

– They are versatile.

– They are ideal for high-production runs.

– They are cost-effective.

– They produce strong welds that can withstand high stress and strain levels.

Cons

– They require intensive, regular maintenance.

– Weld quality may be affected by the thickness and size of the metal.

Flash butt welding machine

Resistance flash welders use a high-voltage current that passes between the two pieces of metal to weld them much faster than other methods. The machines are appropriate for applications where a quick and strong bond is needed and for welding thinner metals.

Pros

– They produce strong welds fast.

– They are versatile.

– They are consistent in producing high-quality welds.

Cons

– They offer limited portability as they are immobile.

– They have high energy consumption levels.

Seam welding machine

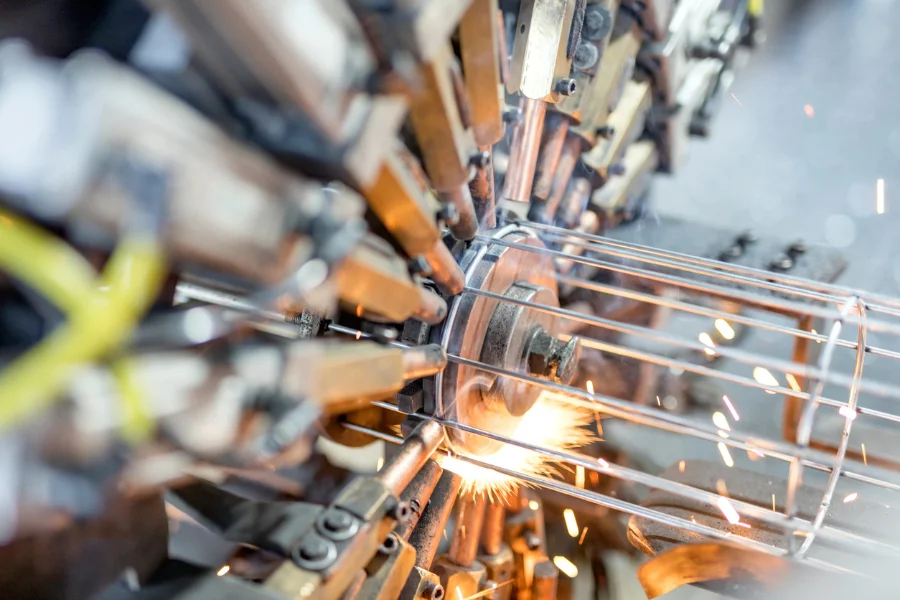

A seam welding machine is a specialized welder that creates a continuous, homogeneous weld on metal sheets. It is a resistance spot welding machine suitable for welding thin metal sheets together without needing flux or filler materials.

Pros

– They provide precise and accurate welds, which makes them suit most fabrication projects.

– They can fabricate a wide range of metals.

– They can produce strong welds consistently.

Cons

– To attain their high level of accuracy, they require lots of maintenance.

– Operating the machines requires a lot of understanding of welding techniques and parameters.

Conclusion

Spot welders can be a good investment for both new and experienced businesses in the welding sector. This guide shows the types of spot welders and what factors to consider when choosing dependable machines. Welding processes should therefore be smooth when working with reliable spot welders.

Also read: The Differences Between MIG and TIG Welding