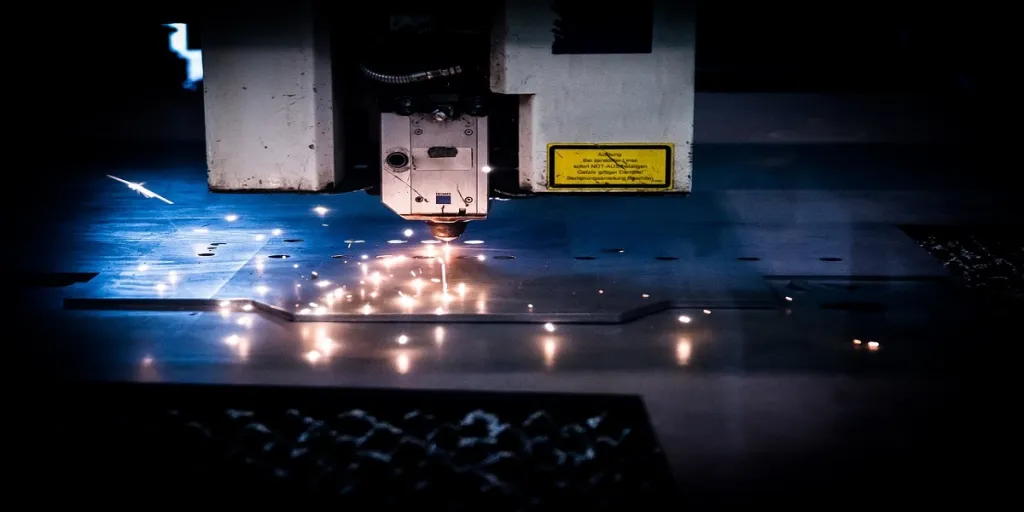

Laser cutting machines are known for cutting metals using laser beams—concentrated forms of energy directed to one area. This technology is efficient, fast, and highly reliable. However, to guarantee similar results every time the machine is used, proper maintenance of the laser cutter will have to be conducted. This guide highlights the best practices for maintaining laser cutting machines.

Table of Contents

Why it is important to maintain a laser cutting machine

Structure of a laser cutting machine

How to maintain a laser cutting machine

Final thoughts

Why it is important to maintain a laser cutting machine

Maintenance of a laser cutting machine should be taken seriously if the machine is to work optimally and for long periods. When cutting materials such as MDF and acrylic, a lot of fumes are released while dust and debris collate in the cutting machine. If these particles are not taken care of, they can lead to severe problems such as overheating and system failures, which could cause downtime of the device. Regularly maintaining the laser cutter will reduce unexpected machine breakdowns.

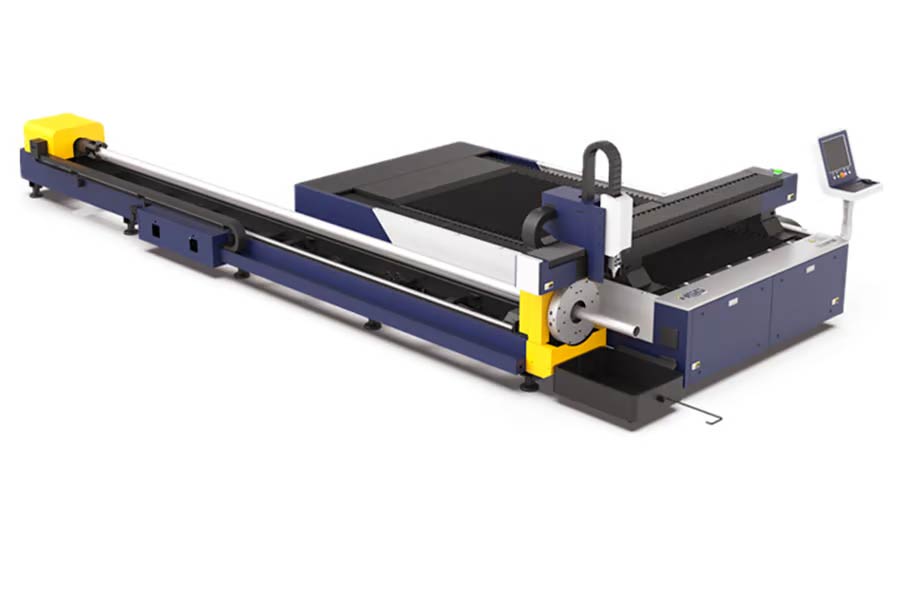

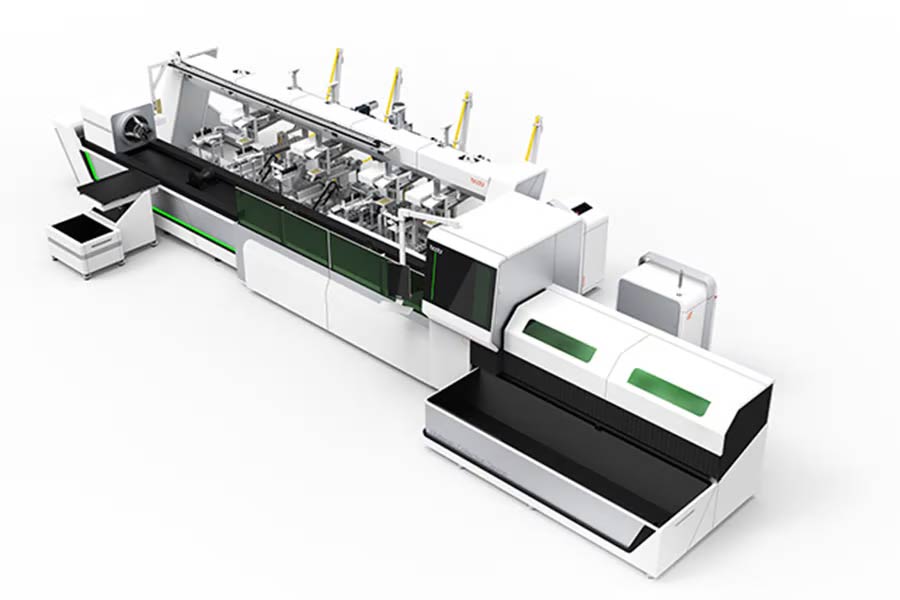

Structure of a laser cutting machine

As outlined below, laser cutting machines have several components.

Laser oscillator: It is contained in the laser head, which generates the laser beam.

Reflecting mirrors: They direct the laser beam in the right direction and have protective covers to prevent the beam from malfunctioning.

Cutting torch: It comprises the focusing lens, the laser gun body, and the auxiliary gas nozzle.

Cutting torch driving device: It is used to carry the cutting torch along the X and Z axes as directed by the computer program. It comprises a motor and lead screw.

Gas cylinders: They supply gas for laser oscillation and auxiliary gas for cutting.

Control panel: It consists of controls used to direct the entire cutting process of the machine.

Air pump: It is used to supply clean and dry air to the laser tubes and beam path to ensure they function normally.

Laser power supply: It supplies power to the laser tubes to generate the laser beam, which is reflected through mirrors to the required workpiece.

How to maintain a laser cutting machine

Mirror and lens

The optics of the laser cutting machine comprise the lens and the mirror. When dust and other materials stay for long, they can combust onto the surface of the optics, which leads to blurry lines. The laser beam can also become weak, leading to poor laser cutting. Cleaning of the optics is therefore essential to prevent their permanent damage. It is recommended to clean them carefully every 10-40 hours with acetone or IPA solution and some cotton buds.

Exhaust fans

Dust can cause a lot of damage to the fans of the laser cutting machine. An ideal solution is installing a fume filter that cleans the air before being directed into the device’s fan. However, the fans can still be cleaned effectively even if a filter has not been installed. Any accumulation of dust and debris on the impeller on the extractor fans should be cleaned off. Materials such as MDF and acrylic release a lot of fumes when being cut, and they can be a fire hazard if not attended to properly. Cleaning can be done by disconnecting the fan from the power supply and removing the extraction hose pipes before cleaning the impeller fan. Ducting should be done on the inlet and exhaust pipes with a soft paintbrush every 40 hours.

Tube filter

The tube filter, too, should be cleaned of any impurities it may have. The water in the tube should be drained and removed before cleaning. A 50-50 mixture of water and vinegar should be used to rinse the tube before it is reattached to the water inlet and restored in the machine.

Water cooler

Laser cutting machines generate a lot of heat when in operation. They come with water coolers, also known as water chillers. The temperature of the water cooler should be monitored through the display. Every few weeks, the filters in the cooler should be inspected for material build-up. Any material should then be removed. Water contamination should also be inspected to ensure that the water does not lead to rusting of components in the cooler. The water used should be deionized because ordinary water contains impurities that can clog pipes and filters or encourage bacterial growth. It is also essential that chlorine is not used during maintenance because the chloride ion attacks the passive layer of stainless steel or copper components that may be in the cooler.

Laser head/source

The laser head/laser source is where the beam originates, and it too requires maintenance. Cleaning the laser head should begin by blowing off dust and lint using compressed air. Detergent/cleaning fluid and cleaning wipes are recommended for cleaning. The head should first be rinsed using the cleaning fluid. Then, a drop of the cleaning fluid should be placed on the head and left for a minute. The head should be wiped with the cleaning wipes and stored ready for use.

Guide rail

The guide rails are essential to a laser cutting machine because they provide guidance and stability. They, therefore, affect the processing accuracy of the machine. Failure to maintain them could lead to corrosion spots, affecting the movement of the laser cutter. The operator should move the laser cutter to one side of the rail and wipe off all the dust with a dry cotton cloth. A little sewing oil should be poured on the rail, and the laser head should be pushed across the guide rail to spread the oil evenly.

Final thoughts

Good maintenance is paramount to maintaining the performance of laser cutting machines. This is why this guide has gone to great lengths to explain the critical parts that need to be keenly looked at in maintenance. Visit Alibaba.com for a selection of the best laser cutting machines available.