Table of Contents

● Introduction

● Market overview

● Different types and their features

● Things to consider when selecting products

● Conclusion

Introduction

Cables and accessories play a crucial role in modern electronics, facilitating seamless connectivity and functionality across a range of devices and applications. Driven by rising electricity demand and technological advancements, the cable industry continues to evolve. Selecting the right cables involves understanding their types, features, and application-specific requirements. This guide delves into market trends, types of cables, and essential considerations for choosing the best products.

Market overview

Market scale and growth

The global cable accessories market was valued at $49.5 billion in 2020 and is projected to reach $99.3 billion by 2030, registering a CAGR of 7.2%. This growth is driven by the rising demand for electricity across various industries, including oil and gas, construction, and manufacturing. The market segments include low, medium, and high voltage applications, with the high voltage segment holding the largest market share due to its demand in industrial applications.

Regional insights

Asia-Pacific dominated the market in 2020 and is expected to maintain this lead throughout the forecast period. This dominance is attributed to the region’s rapid industrialization, significant demand for power infrastructure, and the presence of key market players. Countries such as China, Japan, India, and Australia are major contributors to the market’s growth, driven by increasing power generation and distribution needs.

Different types and their features

Power cables

Power cables are essential for transmitting electrical power and are constructed with high-conductivity materials like copper or aluminum. Copper conductors, though more expensive, offer superior conductivity, lower resistance, and a longer lifespan compared to aluminum. Power cables are insulated with materials such as PVC, XLPE (cross-linked polyethylene), and rubber, chosen for their dielectric properties, thermal resistance, and flexibility. These cables can handle high current loads, typically ranging from 10 to 500 amperes, and are used in applications such as power distribution, industrial machinery, and commercial lighting. For instance, XLPE insulation can withstand temperatures up to 90°C, making it suitable for high-voltage environments.

Control cables

Control cables are designed for transmitting control signals in automation and process control systems. They are often constructed with multi-core copper conductors, insulated with PVC, and may include shielding to prevent electromagnetic interference (EMI). These cables typically support current capacities of up to 10 amperes and are rated for voltages between 300 to 600 volts. Control cables are used in a wide range of applications, including industrial automation, robotics, and machine control, where precise and reliable signal transmission is critical. The insulation materials provide resistance to oils, chemicals, and mechanical stress, ensuring durability in harsh industrial environments.

Data cables

Data cables, such as Ethernet and USB cables, are vital for data transmission in networking and communication systems. Ethernet cables, classified into categories like Cat5e, Cat6, and Cat6a, offer varying levels of performance, with Cat6a supporting speeds up to 10 Gbps over a maximum distance of 100 meters. These cables consist of twisted pairs of copper wires, typically 24 AWG (American Wire Gauge), which help reduce crosstalk and EMI. USB cables, used for data transfer and power delivery between devices, are available in versions like USB 2.0, 3.0, and 3.1, with data transfer rates up to 10 Gbps. The cables are constructed with multiple conductors, insulated with materials such as PVC, and often include shielding to protect against signal interference.

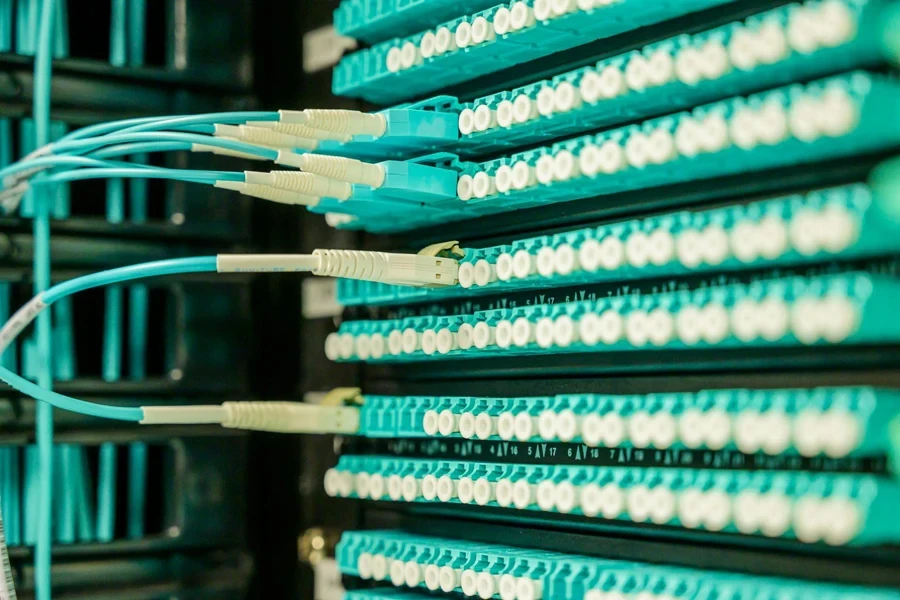

Fiber optic cables

Fiber optic cables are designed for high-speed data transmission over long distances using light signals. They consist of a core made of glass or plastic fibers, surrounded by a cladding layer with a lower refractive index to keep the light signals confined. These cables can support data rates exceeding 100 Gbps and are immune to electromagnetic interference. Single-mode fibers, with a core diameter of approximately 9 micrometers, are used for long-distance communication, while multi-mode fibers, with core diameters ranging from 50 to 62.5 micrometers, are suitable for shorter distances. The outer protective jacket, made from materials like PVC or polyethylene, provides mechanical strength and environmental protection.

Coaxial cables

Coaxial cables are used for transmitting high-frequency signals and consist of a central conductor, usually copper, surrounded by an insulating dielectric layer, a metallic shield, and an outer insulating jacket. The central conductor’s typical size ranges from 20 to 10 AWG, and the shield can be made of braided copper or aluminum foil, which helps reduce signal loss and protect against EMI. Coaxial cables are capable of transmitting signals up to 3 GHz, making them suitable for applications like television broadcasting, cable internet, and satellite communications. The dielectric material, often polyethylene foam, maintains the cable’s impedance and reduces signal attenuation.

Specialty cables

Specialty cables are designed for specific applications, such as automotive, marine, HDMI, and audio/video cables. Automotive cables must withstand extreme temperatures, chemicals, and mechanical vibrations, often featuring conductors made from tinned copper for corrosion resistance and insulation materials like cross-linked polyethylene. Marine cables are built to endure harsh marine environments, with materials resistant to saltwater, UV radiation, and oil, typically featuring tinned copper conductors and neoprene or EPR (ethylene propylene rubber) insulation. HDMI cables, used for high-definition video and audio transmission, can support resolutions up to 4K and beyond, with data rates up to 18 Gbps, and are constructed with multiple twisted pairs of copper wires, shielded to prevent EMI. Audio/video cables, such as RCA and XLR cables, are used in home theater systems and professional audio equipment, designed to carry analog or digital signals with minimal interference, often featuring gold-plated connectors for better conductivity and corrosion resistance.

Things to consider when selecting products

Voltage and current capacity

When selecting cables, it is crucial to ensure that the voltage rating exceeds the system’s maximum voltage to prevent insulation breakdown. For instance, a cable rated for 600V should not be used in a 1kV system. Similarly, current capacity must match the load requirements to avoid overheating. Cables are typically rated in amperes, and using a cable with an insufficient current rating can lead to excessive heat generation. For example, a 10 AWG copper cable, with a current capacity of approximately 30 amps, should not be used for applications requiring higher loads.

Material and construction

The choice of materials for both the conductor and insulation significantly affects a cable’s performance. Copper, with its lower electrical resistance (1.68 µΩ·cm), provides better conductivity than aluminum (2.82 µΩ·cm), making it the preferred material for high-performance applications. Insulation materials like PVC, XLPE, and Teflon have distinct properties: PVC is cost-effective and flame-retardant, suitable for general use; XLPE offers high thermal resistance (up to 90°C) and mechanical strength, ideal for industrial environments; Teflon, with its exceptional chemical resistance and temperature tolerance (up to 260°C), is used in harsh conditions. The outer jacket, whether PVC, rubber, or nylon, protects against physical damage, moisture, and chemicals, with rubber being preferred for underground and underwater applications due to its superior water resistance.

Installation environment

Cables for overhead installations need to be lightweight and capable of withstanding environmental factors like UV radiation and wind. Overhead cables often use ACSR (Aluminum Conductor Steel Reinforced) for added strength. Underground cables require robust insulation and armoring to protect against mechanical stress and moisture ingress. These cables are typically armored with steel wire or tape for added durability. For underwater applications, cables are designed with multiple layers of insulation and waterproofing to resist pressure, saltwater, and other corrosive elements. These might include layers of polyethylene and rubber, along with a lead sheath for additional protection.

Safety and compliance

Adhering to safety standards and regulations is essential. For example, cables used in hazardous environments must comply with ATEX or IECEx standards, which ensure they are safe for use in explosive atmospheres. Flame-retardant cables, classified under standards like UL 1581 or IEC 60332, are critical in preventing fire propagation. Low Smoke Zero Halogen (LSZH) cables, which emit minimal smoke and toxic gases during combustion, are preferred in public buildings and confined spaces. Regular compliance checks and certifications ensure that the cables meet these stringent requirements.

Future-proofing

To future-proof installations, selecting cables with higher performance ratings than currently needed is prudent. For instance, using Cat6a Ethernet cables, which support data rates up to 10 Gbps, instead of Cat5e, ensures compatibility with future network upgrades. In power distribution, choosing cables with a higher ampacity can accommodate future increases in load without requiring a complete rewiring. Additionally, considering advancements in smart grid technology, cables that support higher bandwidth and communication capabilities can be beneficial for integrating future smart devices and systems.

Conclusion

Cables and accessories are indispensable in the consumer electronics sector, offering a wide range of types and features to meet diverse application needs. Understanding market trends and carefully selecting the appropriate products are essential for optimizing performance and ensuring longevity in various industrial and commercial settings. As technology advances and demands evolve, the right choice of cables will continue to play a critical role in maintaining efficient and reliable electronic systems.