Table of Contents

1. Historical development of plugs and sockets

2. Common types of plugs and sockets

3. Plugs and sockets global market size

4. Plug and socket selection guide

5. Recent advances in plug and socket technology

6. Summary

1. Historical development of plugs and sockets

Plugs and sockets are complementary components, and their development is interdependent. With the widespread adoption of Edison’s invention of the electric light, electrical connections became a critical problem to be solved. In 1882, Thomas Tayler Smith of the UK applied for a patent for his electrical circuit connector, recognized as the earliest socket. This type of socket was specifically designed for electric lamps and could only be connected to the base of the lamp.

In 1904, Harvey Hubbell of the United States invented a more convenient two-pin plug and socket. He designed two round pins on the plug, which evolved through experimentation into two flat pins. A locking mechanism allowed the plug to be secured in the socket, improving the convenience and efficiency of the socket. This design is still in use today. Another milestone in socket development came in 1920 with the introduction of the third pin, known as the earth pin. Its presence increased the safety of the socket by protecting the user in the event of a short circuit in the wiring.

Due to the rapid and widespread adoption of electrical technology, a single global standard for plugs and sockets has not been established. Different regions have developed different standards for plugs and sockets based on factors such as technology, safety, economics, geography, and politics, taking into account their local electrical standards. The International Electrotechnical Commission (IEC) has made several attempts to create a globally accepted standard for electrical plugs and introduced the International Type N Socket Standard in 1986. However, due to various political and economic constraints, the development and implementation of international standards have not been entirely successful. It was not until 2007 that Brazil became the first country to adopt the Type N standard.

Interestingly, the map of plugs and socket outlets in use around the world today reflects the network of global capitalist colonial expansion in the first half of the 20th century. As one American anthropologist has noted, correctly guessing which type of plug and socket a country uses requires a good understanding of the history of the First and Second World Wars and a keen interest in post-colonial literature.

2. Common types of plugs and sockets

Due to historical and other factors, there has been a wide variety of plug types. Below are some common ones that differ from production standards, appearance characteristics, and electrical parameters:

| Type/ standard | Area and shape | Specificities | Diagram |

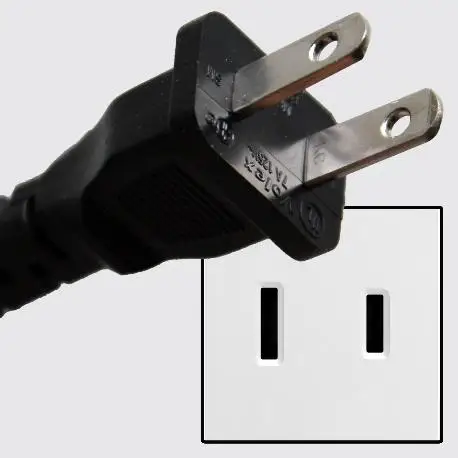

| Type A: NEMA 1-15 | ● USA, Canada, Mexico, and Japan ● Flat electrodes | ● 2-pin ungrounded ● 15A 100-127V |  |

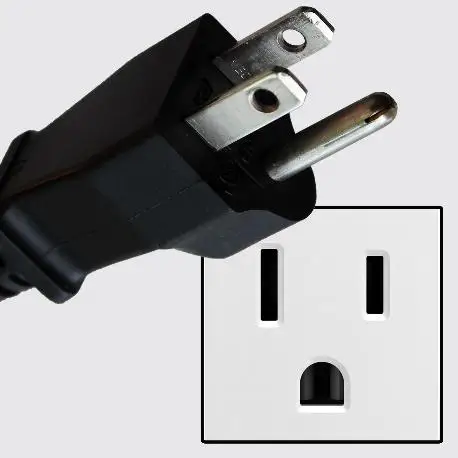

| Type B: NEMA 5-15 | ● USA, Canada, and Mexico ● Flat electrode and protective earth wire | ● 3-pin grounding ● 15A ● 100-127V |  |

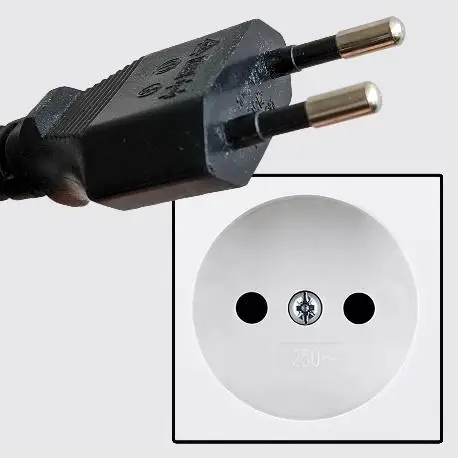

| Type C: CEE 7/16 | ● Europe, South America, and Asia ● Round electrode | ● 2-pin ungrounded ● 2.5A, 10A, 16A ● 220-240V |  |

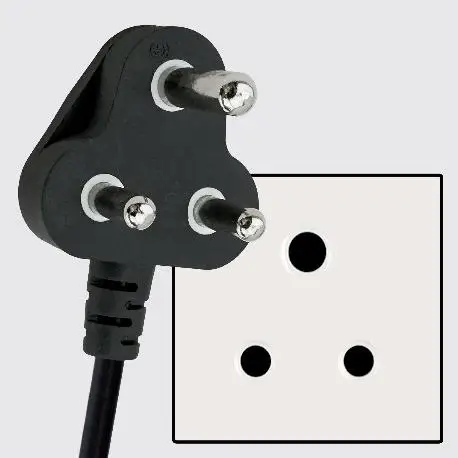

| Type D: BS 546 | ● India, Pakistan, Israel, and some African countries ● Round electrode and protective earth wire | ● 3-pin grounding ● 5A ● 220-240V |  |

| Type G: BS 1363 | ● UK, Ireland, Malta, Malaysia, and Singapore ● Flat electrode and protective earth wire | ● 3-pin grounding ● 13A 220-250V |  |

| Type I: AS/NZS 3112 | ● Australia, New Zealand, China, and Argentina ● Flat electrode and possible protective earth wire | 2/3-pin/2-pin grounding, 2-pin ungrounded ● 10A ● 220-240V |  |

Differences in standards between regions have led to considerable inconvenience and given rise to a wide range of travel plug adapters. These adapters are designed to convert plugs to fit sockets of different standards, making it easier to use electrical appliances from other countries or regions, especially when traveling.

In addition, special types of plugs are designed for specific scenarios, such as low voltage information plugs (e.g., telephone plugs), USB sockets, aviation plugs designed for high power, specific frequencies, high reliability, and special interfaces for charging electric vehicles. These plugs and sockets support our electrical equipment in specialized scenarios.

3. Plugs and sockets global market size

Due to the widespread use of electrical equipment, plugs and sockets have a significant market share in both consumer electronics and industrial sectors.

According to Cognitive Market Research findings, the 2023 valuation of the Global Test Socket Market stands at a substantial USD 1.8 billion, poised to experience a noteworthy compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Concurrently, insights from Business Research highlight the global USB wall socket market, indicating its 2022 worth at USD 419.4 million and forecasting an ascent to USD 672.7 million by 2031, manifesting a steady CAGR of 5.4% throughout the forecast period. Additionally, Mordor Intelligence foresees a dynamic trajectory for the smart plugs market, projecting an impressive surge from USD 2.69 billion in 2023 to a substantial USD 9.12 billion by 2028, at an exceptional CAGR of 27.66% within the forecast period spanning from 2023 to 2028.

It is predicted that the market for plugs and sockets, as a fixed demand for electrical equipment, will continue to develop and expand in the future.

4. Plug and socket selection guide

Undoubtedly, the first consideration when selecting plugs and sockets is the requirements of the electrical equipment, focusing on interface types, regional standards, power requirements, current, voltage, matching resistance, and the need for earthing.

As an individual user, compatibility, convenience of plug and socket locations, and layout should be taken into account. When arranging sockets, place them vertically rather than horizontally to prevent dust from getting into the slots, which could lead to short circuits and fire hazards.

Travelers should opt for plugs that are portable and highly adaptable. For uses in business settings, factors such as serviceability and durability should be prioritized alongside industry standards and manufacturing procurement costs. Choosing plugs and sockets that are durable and easy to maintain can reduce the frequency of replacements and repairs, ultimately improving production efficiency. Special production environments like those with dust and moisture require streamlined wiring layouts and enhanced receptacle protection.

Consideration of environmentally friendly plugs and sockets aligns with the trend towards sustainable development, reducing environmental impact.

Finally, regardless of the type of plugs and sockets chosen, attention should be paid to safety certifications and quality. Safety is paramount. For your reference, here are some common safety certification standards for different regions. When using plugs and sockets in a particular region, it’s advisable to check the local safety certifications:

- UL certification: Issued by Underwriters Laboratories; applicable to the US and Canadian markets, ensuring that products meet safety standards in North America

- CE certification: Indicates compliance with European Union safety, health, and environmental requirements, allowing free movement in the European market

- CCC certification: China Compulsory Certification; mandatory for products in the Chinese market

- BSI certification: Issued by the British Standards Institution; applicable to products from the UK and some other countries

- VDE certification: Issued by the German Association for Electrical, Electronic and Information Technologies; applicable to Germany and other European countries

- SAA certification: Issued by Standards Australia; applicable to products on the Australian market, ensuring compliance with Australian safety standards

- KEMA certification: Issued by KEMA, the Dutch electrical testing and certification organization; applicable to products in European and other international markets

5. Recent advances in plug and socket technology

With the continuous advancement of technology, there have been notable developments in the plug and socket systems. This article explores the latest research advances in the field, focusing on key areas such as smart socket technology, design and materials, and electric vehicle charging stations.

Smart socket technology

In response to the widespread adoption of smart homes and the development of Internet of Things (IoT) technology, smart socket technology has seen significant advances. The integration of sensors enables remote control and power monitoring, allowing users to set the duration of smart plugs. Control can be achieved through mobile devices or other terminals. In addition, the integration of wireless charging capabilities into sockets has greatly facilitated the use of devices, especially with the proliferation of wireless charging smartphones.

Design and materials

To improve the durability, energy efficiency, and safety of plugs and sockets, researchers are exploring the use of new materials with high-temperature or fire-resistant properties. This contributes to the devices’ longevity and helps produce more convenient and compact plug and socket designs.

Electric vehicle charging stations

As sales of electric vehicles soar, charging stations have become a key component. The increasing demand for charging plugs and sockets tailored for electric vehicles reflects the expansion of the industry. Driven by continuous innovation to improve efficiency, safety, and convenience, this segment is poised for significant market growth in the foreseeable future.

6. Summary

Plug and socket technology links electrical energy in the grid and our devices, providing the essential support to power them. These technologies are evolving to better meet the needs of consumers, with the latest advances being seen in aspects such as power-carrying capacity and intelligent control functions. No matter your plug and socket needs, you’ll find everything you’re looking for on Alibaba.com.