Table of Contents

1. Introduction

2. Types of ice makers and their applications

3. Current market overview for 2024

4. Key factors to consider when selecting an ice maker

5. Top ice maker models for 2025

6. Conclusion

Introduction

In 2025, ice makers have become essential fixtures in commercial settings, offering reliable, high-quality ice production tailored for a range of business needs. From small countertop models to large, commercial-grade machines, today’s ice makers deliver variety, efficiency, and speed, ensuring a steady supply for everything from refreshing drinks in cafés to critical storage in healthcare facilities. Technological advancements mean ice makers are now faster, quieter, and more energy-efficient than ever, while innovations like app controls and self-cleaning systems make them easier to operate and maintain, enhancing operational convenience and customer satisfaction.

Types of ice makers and their applications

Countertop ice makers

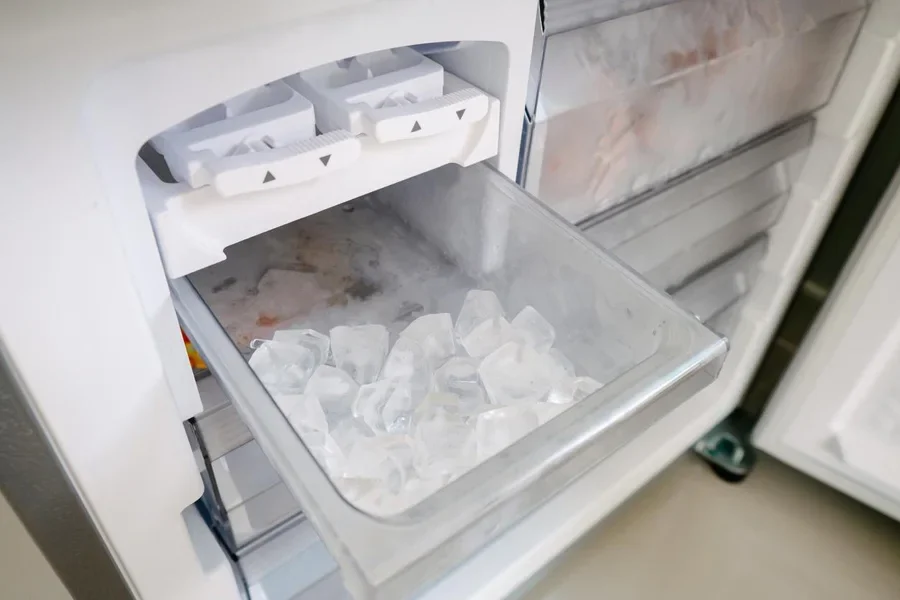

Countertop ice makers are compact, freestanding units designed for efficient use in small spaces with moderate ice needs. These machines excel in locations where mobility is key, such as office break rooms, small event spaces, or home kitchens. Their quick production cycles enable them to make small batches of ice, often nugget or bullet, within minutes. Although limited in storage capacity, they are ideal for environments where frequent refilling is manageable and continuous access to large amounts of ice is unnecessary.

Undercounter and built-in models

Undercounter ice makers offer a seamless and space-saving design, fitting comfortably beneath counters in bars, cafes, and mid-sized restaurants. These models produce a larger volume of ice, such as clear or crescent shapes, suitable for serving beverages without excessive dilution. Due to their steady output and integration into the workspace, undercounter ice makers are a popular choice for businesses with consistent, higher-volume ice demands. Their design maximizes efficiency without dominating counter space, allowing for an uninterrupted workflow in busy environments.

Commercial-grade ice makers

High-capacity commercial-grade ice makers are engineered to meet the demands of large establishments like hotels, restaurants, and hospitals. These robust machines can generate significant amounts of ice, often reaching hundreds of pounds per day. Built for durability and continuous production, commercial models may come in modular or industrial setups and often include energy-efficient features and water-cooled systems that enhance performance while maintaining low noise levels. Their high output and reliability make them indispensable for industries that rely on a steady, large-scale ice supply for customer satisfaction and operational efficiency.

Specialty ice makers

Specialty ice makers cater to unique needs by producing specific ice types—such as nugget, gourmet, or flake ice—designed for specialized applications. Nugget ice, loved for its chewable texture, is often found in quick-service restaurants, adding a unique experience to beverages. Gourmet ice is typically clear and slow-melting, ideal for upscale bars where visual presentation and minimal dilution are priorities. Flake ice, known for its moldable texture, is widely used in food displays and healthcare settings, as it provides reliable cooling without damaging delicate items like seafood or produce. Specialty ice makers allow businesses to tailor their offerings, enhancing both function and customer experience.

Current market overview for 2024

Growth trends and projections

In 2024, the global ice maker market saw steady growth, with an estimated valuation of USD 5.52 billion, according to Zion Market Research. Projections indicate that the market will reach approximately USD 9.23 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.9% from 2024 to 2032. This expansion is primarily driven by increased demand from sectors like hospitality, healthcare, and food services, where high-capacity and reliable ice production are essential for daily operations. Regions such as Asia-Pacific are expected to play a significant role in this growth due to urbanization and rising disposable incomes, driving demand for commercial and industrial ice makers. In North America and Europe, a strong presence in hospitality and healthcare continues to fuel demand for efficient, durable models that meet industry and regulatory standards.

Innovations and technological advancements

Technological advancements in the ice maker industry are progressing, with newer models integrating app-based controls, remote monitoring, and automation to cater to high-demand environments such as restaurants and hospitals. These smart features allow businesses to optimize ice production and monitor performance in real time, adding convenience and operational efficiency. Self-cleaning capabilities and improved filtration systems are also enhancing hygiene standards and reducing maintenance needs. Additionally, the industry is witnessing a shift toward eco-friendly models, with manufacturers focusing on sustainable refrigerants and energy-efficient designs. These features not only appeal to environmentally conscious buyers but also reduce operational costs and help ensure regulatory compliance.

Environmental impact and regulations

Environmental considerations are playing a critical role in the ice maker market as regulations increasingly mandate lower emissions and energy consumption. Many manufacturers are now prioritizing sustainable refrigerants, such as hydrocarbon-based options, which offer low global warming potential (GWP) and zero ozone depletion potential (ODP). These environmentally friendly advancements align with global energy standards and meet market demand for lower environmental impact. Additionally, water-efficient designs and enhanced insulation are becoming more popular, helping conserve resources and reduce operating costs. This regulatory focus on sustainability is shaping both product innovation and buyer choices, with businesses increasingly prioritizing ice makers that align with stringent environmental and operational standards.

Key factors to consider when selecting an ice maker

Capacity and production rate

The right ice maker should match the daily ice needs of the business. Restaurants may need about 1.5 pounds of ice per customer, while bars could require up to 3 pounds per customer for drinks. A buffer of about 20% helps prepare for peak demand. Some factors, like high room temperatures, can also affect ice production, so choosing a model with a slightly higher capacity than usual needs is often beneficial.

Ice type preferences

Different types of ice suit various applications. Nugget ice, which is soft and chewable, is favored in healthcare and quick-service settings. Gourmet ice, which melts slowly and maintains drink quality, is popular in high-end bars. Cube ice, a versatile choice, is widely used in food service. Selecting the right type ensures the ice serves its purpose well, whether it’s for drinks, displays, or specialty needs.

Maintenance and durability

Regular maintenance keeps an ice maker working efficiently and prevents breakdowns. Models with self-cleaning features simplify upkeep and reduce labor costs, especially valuable in busy commercial environments. Choosing a durable model with easy-access maintenance features can extend the machine’s lifespan and cut down on unexpected repair costs.

Size and installation requirements

Size and installation depend on space availability and demand. Small countertop models are ideal for limited spaces with lower ice needs, while larger freestanding units are better suited for high-demand establishments with ample space. It’s also important to check if there’s access to electrical outlets, drainage, and adequate ventilation, especially for air-cooled machines, to ensure smooth operation.

Energy efficiency

Energy-efficient ice makers help lower operational costs and reduce environmental impact. Models with ENERGY STAR certification, for instance, can save on both energy and water usage over time. Air-cooled models tend to be more eco-friendly and cost-effective, while water-cooled options offer efficient cooling but require more water. Choosing a model with sustainable refrigerants and energy-efficient features can support both cost savings and environmental goals.

Top ice maker models for 2025

Best countertop ice makers

Countertop ice makers are highly valued for their compact design and portability, making them ideal for small spaces or businesses with moderate ice needs. These models can produce ice quickly, typically yielding between 24 to 44 pounds per day. Many modern countertop units offer options for different ice shapes, such as bullet or nugget ice, which are popular in both casual dining and healthcare settings. Some units feature self-cleaning capabilities and intuitive controls, which enhance ease of use and maintenance. These machines are perfect for locations like cafés, office break rooms, or smaller venues where a steady supply of ice is needed without taking up much counter space.

Leading undercounter and built-in units

Undercounter and built-in ice makers provide a seamless integration into kitchens and workspaces, making them a popular choice for high-traffic environments such as restaurants, bars, and hotels. These machines typically produce between 25 to 100 pounds of ice per day, with storage capacities ranging from 6 to 30 pounds. Models designed for commercial use often include features like adjustable ice cube sizes and digital control panels for easier customization. Their stainless-steel construction ensures durability and long-term performance, while many also offer energy-efficient options that align with environmental standards. The ability to fit into tight spaces without sacrificing production makes these units ideal for busy businesses that require consistent, high-quality ice.

Top commercial-grade ice makers

Commercial-grade ice makers are built for heavy-duty operations and are essential in industries with high daily ice demands. These machines can produce hundreds of pounds of ice per day, with some models reaching up to 400 pounds or more. They are commonly found in large venues such as hotels, hospitals, and large-scale food service establishments. Advanced features often include high production rates, energy-saving systems, and self-cleaning mechanisms to reduce maintenance costs. These machines are designed for continuous operation, ensuring that even during peak business hours, there is a steady supply of ice. Commercial units are known for their durability and reliability, offering long-term performance even in the most demanding environments.

Notable specialty ice makers

Specialty ice makers cater to niche markets by offering unique ice types such as nugget, gourmet, or flake ice. Nugget ice, which is soft and chewable, is particularly popular in healthcare and quick-service restaurants. Gourmet ice is often used in upscale dining environments due to its crystal-clear appearance and slower melting properties, which enhance drink presentation. Flake ice is favored in food displays, particularly for seafood and produce, as it easily molds around items and maintains a consistent cooling effect. These machines are perfect for businesses that want to offer a unique customer experience or meet specific operational needs. Specialty ice makers also come with advanced features such as energy-efficient designs and adjustable ice sizes, making them versatile for a range of applications.

Conclusion

Choosing the right ice maker is key to ensuring long-term operational efficiency and meeting business-specific needs. Whether opting for compact countertop units, space-saving undercounter models, or heavy-duty commercial machines, factors such as production rate, ice type, maintenance requirements, and energy efficiency should all be considered carefully. Specialty ice makers, with options like nugget and gourmet ice, further enhance service by catering to unique demands. With advancements in technology and sustainable practices shaping the market, selecting an ice maker that aligns with both operational goals and environmental standards ensures a valuable, long-term investment.