Backhoe loaders have evolved from a basic tractor body, with additional fittings, to the purpose-built machines of today. Meanwhile, tractors, with the added loader and backhoe attachments, compete for the same market and look and function much the same. Backhoe loaders are sometimes referred to as tractor backhoe loaders, but more often are called JCBs (after the first branded models). Backhoe loaders are very durable machines and, as replacement parts are readily available, machine life can be extended for many years. The used backhoe loader market is large and there is a wide selection of used machines available. This article looks at some of the available choices for used backhoe loaders, and offers guidance on what to consider when choosing a model right for you.

Table of Contents

Used backhoe loader market overview

A look at used backhoe loaders available on Alibaba.com

Important notes on physical inspections

Final thoughts

Used backhoe loader market overview

The market for new backhoe loaders is projected to grow at a compound annual growth rate of 7.1% from 2021 to 2030. However, the used backhoe loader market is also expected to show substantial growth across the same period. The used equipment market is estimated to be three to four times the size of the new equipment market, with much of the used sales market driven by the post-pandemic economic uncertainty that has impacted the global construction industry. Buyers now face greater cost pressures, with less available capital to spare, and are more cautious of high investment in new machines.

A look at used backhoe loaders available on Alibaba.com

There are plenty of used backhoe loaders available for sale in the open market. Although popular and established brands such as JCB and Caterpillar appear regularly, there are also a wide range of lesser-known brands. This article offers some selected samples from the Alibaba.com marketplace.

| Model: Top One TBL388 Machine weight: 2.5 tons Production year: 2023 Advertised price: US $28,000 |

| Model: Caterpillar Cat 416E Machine weight: 6 tons Production year: 2015 Advertised price: US $32,000 |

| Model: CNMC CN20 Machine weight: 6 tons Production year: 2020 Advertised price: US $19,200 |

| Model: JCB JCB4CX Machine weight: 8 tons Production year: 2015 Advertised Price: USD18,000 |

| Model: Caterpillar Cat 966H Machine weight: 4.7 tons Production year: 2019 Advertised price: US $4,500 |

| Model: JCB JCB3CX Machine weight: 3 tons Production year: 2020 Advertised price: US $20,000 |

| Model: Nuoman NM-LD Machine weight: 4 tons Production year: 2020 Advertised price: US $9,200 |

| Model: Caterpillar Cat 430F Machine weight: 9 tons Production date: 2018 Advertised price: US $36,000 |

Important notes on physical inspections

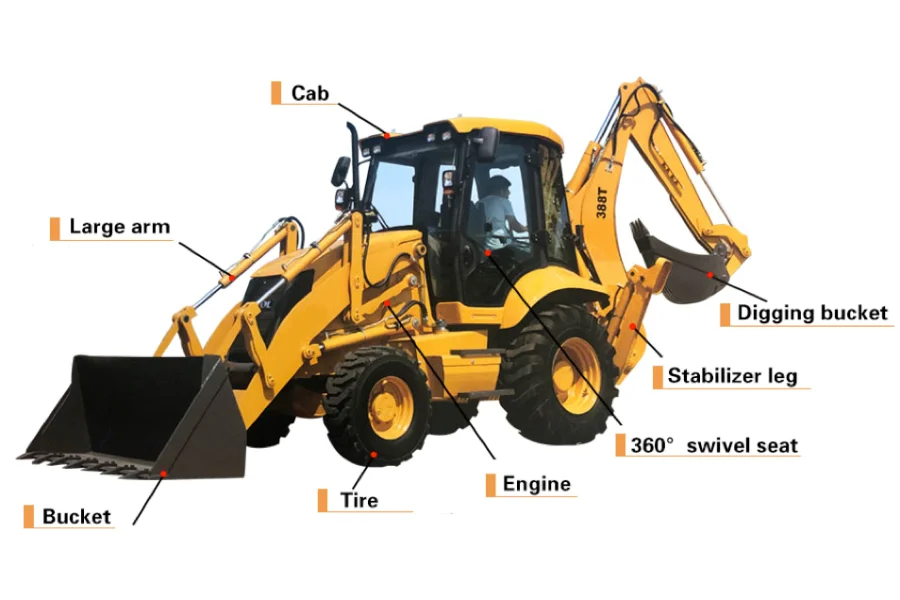

Buying any machine online can be a challenge since it is important to best perform a physical inspection so that the condition of the used machine can be ascertained. The first step is to ask the seller for photos of all key parts and, if possible, videos. Ask the seller for a copy of the maintenance log and/or service records as well as any other available supporting documents, such as receipts for any replacement parts, etc. These offer better insight into how well the machine has been cared for and how well-maintained it is. In addition, here are some suggested areas to look for when physically inspecting a used backhoe loader:

Quick look, first impression

Does the machine look to be in good condition? Is the paintwork clean and does it look touched up or resprayed? Are there signs of rust and peeling? This could mean the backhoe loader was exposed to harsh weather. Are the front and rear buckets clean and undamaged? Do the engine and chassis look well cared for and well-maintained?

Check the engine

Visually inspect the engine for leaks. Start the engine and check for any dripping from under the engine or hoses. Listen for any knocking or clattering from the engine, which could indicate cylinders or valve problems. Is there any white or black smoke? If the engine is Euro 5 or Euro 6 certified, check that the exhaust emissions are within range. Check that the air filter is clean. Check the maintenance record for how frequently the oil and air filters were changed.

Check the driver’s cab

Check for damage within the cab. Does the seat look clean and intact and does it rotate smoothly? Do the joysticks and pedals function and are all instruments clean and working? Check the tachometer for the recorded hours of operation and does this match the maintenance record?

Check the chassis and tires

Check the tires for cracks or tread wear. Is there plenty of tread left? Are the wheel rims damaged? Are the axles in good condition and well-greased? Damaged chassis components or worn tires can be expensive to replace.

Check the front and rear buckets

Is there any damage to either of the buckets? The buckets work with hard ground and dig rough materials, so damage can happen, but any damage should have been repaired. Check the sides or undersides of the buckets and check that all the bucket teeth are intact. Check that the pins and bushings on the buckets are tight and that there is no excessive sideways movement.

Check the booms and arms

Check both the front arms and the rear backhoe boom and arm. Do they show any signs of damage or repair? Are there any welded patches? Are the cylinders clean and smooth? Check all movements with the joysticks and ensure that they are responsive and smooth. Lay the backhoe bucket on the ground and rock it slightly from side to side and forward and back. Check if there is excessive play anywhere along the backhoe boom, arm, and bucket. Are all joints well-greased? New grease is a good thing, but hard and caked grease that has not been changed regularly can lead to excessive wear and tear.

Check the front, rear, and stabilizer hydraulics

A backhoe loader has plenty of hydraulics to check. The front boom uses hydraulics to raise and lower it, and more to adjust the bucket angle. The backhoe has hydraulics to extend and adjust the boom, raise and adjust the arm, and control the backhoe bucket. The machine also has two stabilizers at the rear that are lowered by hydraulics. In each case, check that the hoses and o-rings have a tight seal. Check the maintenance records for how frequently the hydraulic fluid has been topped up or changed. If it has been topped up unusually frequently, this may indicate a leak, which will affect pressure and power.

Final thoughts

Used backhoe loaders are popular and readily available in the secondhand market, and as long as the machines are well-maintained, can be a very good buy. The challenge is establishing that the desired machine has been well cared for and is still in good condition. It should then continue to work well for many more years, and also potentially be a good value sale at the end of your use.

A buyer should therefore do due diligence to check all maintenance, service, and part replacement records in advance. The buyer will then want to ensure that the machine can be physically inspected, either before or after delivery, with the option to decline the sale if any problems are found. A wise approach is to choose a supplier that guarantees quality and accepts returns or replacements if the buyer isn’t satisfied. For more information on the wide variety of used backhoe loaders available, check out the Alibaba.com showroom.