The “OFweek Cup·OFweek 2023 Laser Industry Annual Selection”, hosted by the high-tech industry portal OFweek and organized by OFweeklaser, was held on August 30, 2023 in Shenzhen, China. For this year’s selection, there were a total of 11 awards. Following the principles of Fairness, Impartiality, and Openness, the awards have been selected through online voting by industry users and multi-dimensional selection by specially invited industry experts.

Shenzhen HAN‘S LD Technology Co., Ltd. won the “OFweek Cup·OFweek 2023 Best Award on Semiconductor Laser Technology Innovation” for its HLD-C-660W976F200 High-Power Fiber Optic Coupling Pump Source.

Established in 2019, HAN’S LD is a wholly-owned subsidiary of HAN’S Laser Technology Industry Group Co., Ltd., specializing in the research and development, production, sales, and services of Laservarious semiconductor modules and systems. HAN’S LD product wavelength range covers blue light to infrared, and laser power ranges from watt level to kilowatt level. Its products are used widely in various fiber laser solid-state lasers, direct semiconductor lasers, medical beauty scientific research, and other fields.

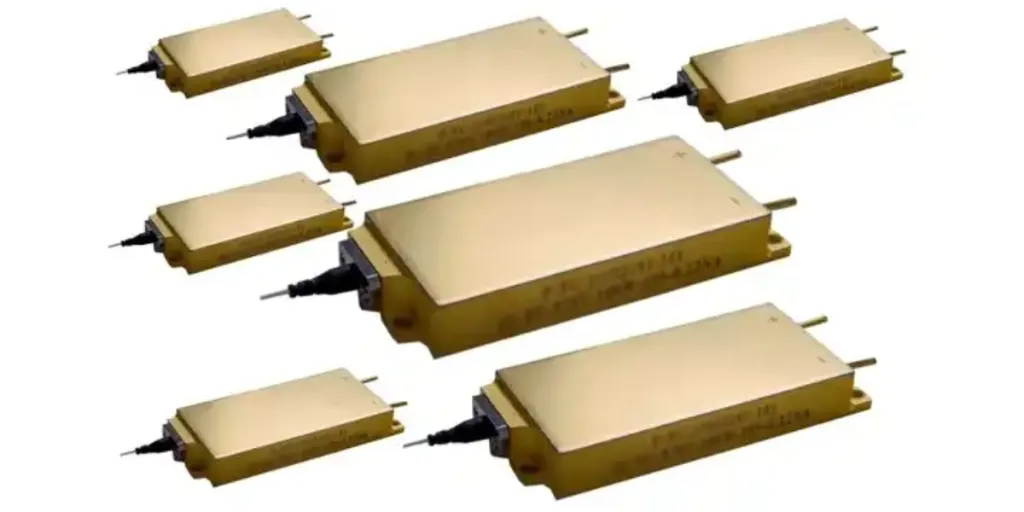

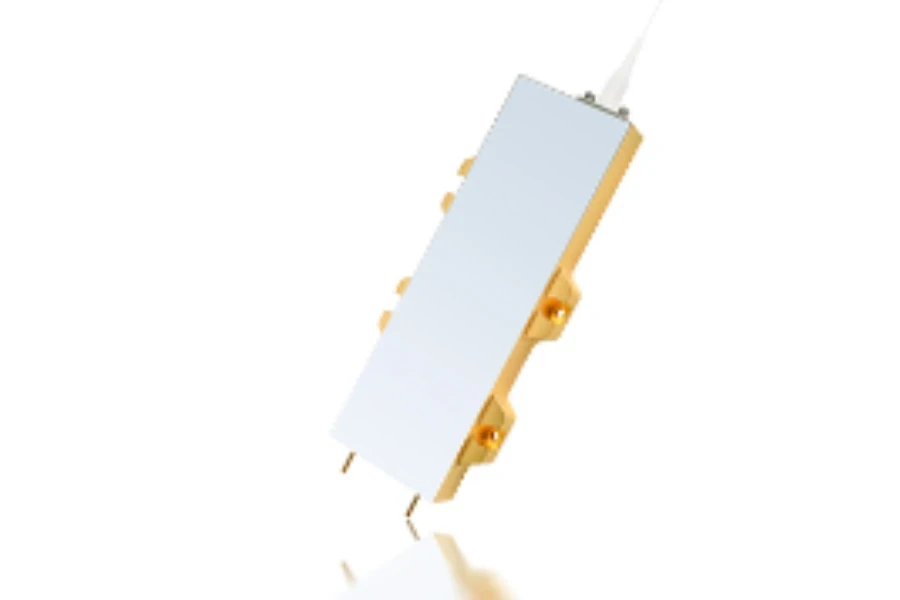

Awarded product: HLD-C-660W976F200 high-power fiber optic coupled pump source

Year of product launch/development background:

HLD-C-660W976F200 high-brightness fiber-coupled semiconductor laser launched in 2022. With the increasing demand for high-power fiber lasers and the urgent need to improve productivity, high-power, high-efficiency, small volume, and lightweight have become the laser light source with an inevitable trend for future development. The power of fiber lasers is increasing. To ensure the laser power, more ordinary fiber coupling semiconductor lasers are needed. It means that the volume and weight of higher lasers will increase, energy consumption will be higher, and the generated heat will require higher power chillers to control temperature. The difficulty in designing high-power fiber lasers has increased, and the drawbacks of ordinary fiber coupling semiconductor lasers are becoming apparent gradually.

HAN’S LD HLD-C-660W976F200 high-brightness fiber coupling semiconductor laser integrates multiple high-power infrared chips with a wavelength of 976 nm in the laser module. Due to the light absorption of a 976 nm semiconductor laser being several times that of an ordinary semiconductor laser, producing lasers of the same power consumes less pump light, which means that a 976 nm semiconductor laser consumes less electrical energy, has higher electro-optical conversion efficiency, and is more energy-efficient, make it more conducive to producing high-power and high brightness fiber lasers. Through the batch application, the HLD-C-660W976F200 high-brightness fiber coupling semiconductor laser has more advantages in thick plate laser cutting, welding, and high reflectivity material processing.

HLD-C-660W976F200 is a high-brightness fiber output semiconductor laser coupled module launched by HAN’S LD. The laser module integrates multiple high-power infrared chips with a wavelength of 976 nm. The manufacturing process of modules is adjusted efficiently through the automated equipment, ensuring the accuracy of the spatial arrangement of all chip launches and the consistency of batch product performance. It has a complete reliability verification and a high standard inspection process and ensures the long-term stability of the product.

The efficient beam combination method and fiber coupling enable the fiber coupling laser module to achieve a fiber core diameter of 200 μm/220 μm with the output power of 660 W, and the electro-optic conversion efficiency can reach over 55%. The laser module is in a unique heat dissipation design, which makes temperature distribution more uniform, transmission faster, and has high heat dissipation efficiency. The angle of the laser module output beam is limited, with NA (95% energy) less than 0.165, creating favorable conditions for downstream use.

Source from ofweek.com