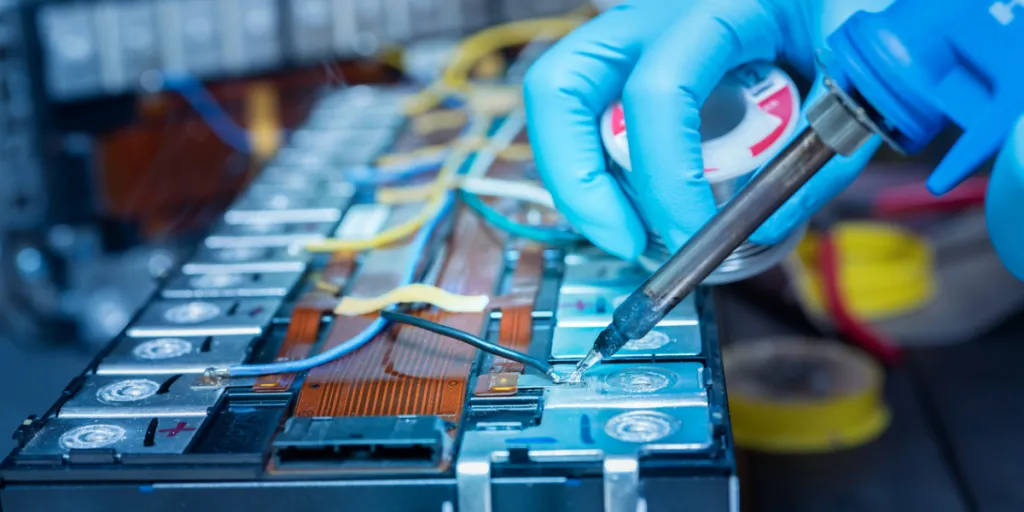

In the past two decades, lithium-ion batteries have been widely used in portable devices such as phones, laptops, and portable power supplies because of their outstanding performance. They are favored for their high energy density, long cycle life, minimal memory effect, and controllable shape design, and the role they play in people’s lives is extremely important.

Not only that, in the last five years, lithium-ion batteries have also become recognized as the best power source for hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles, and electric vehicles. However, while bringing great convenience, lithium-ion batteries also bring some potential dangers, and accidents caused by combustion and explosion occur on occasion.

As lithium-ion batteries occupy an increasingly important position in people’s lives, their safety performance has attracted more and more attention. Here we’ll discuss why lithium-ion batteries continue to be one of our most reliable sources of energy and what is done to ensure they remain safe.

Table of Contents

Why lithium-ion batteries are integral to our daily lives

Lithium-ion battery safety issues

The lithium-ion battery safety performance evaluation index

Lithium-ion battery safety improvement strategies

Battery usage and maintenance recommendations

Why lithium-ion batteries are integral to our daily lives

Since the end of the 19th century to the beginning of the 20th century, with the progress of science and technology and the need for industrial development, electric energy has become an indispensable energy source for humans. We’ve long sought and developed devices that can efficiently store electrical energy, trying capacitors, compressed air energy storage, liquid air energy storage, etc., finally settling on chemical batteries.

The earliest chemical battery can be traced back to the lead-acid battery during the 19th century. Then, after 200 years of continuous development, the lithium-ion battery was born. Because of its high energy density, high cycle life, low environmental pollution, and other factors, lithium-ion batteries quickly became the most widely used battery around the world.

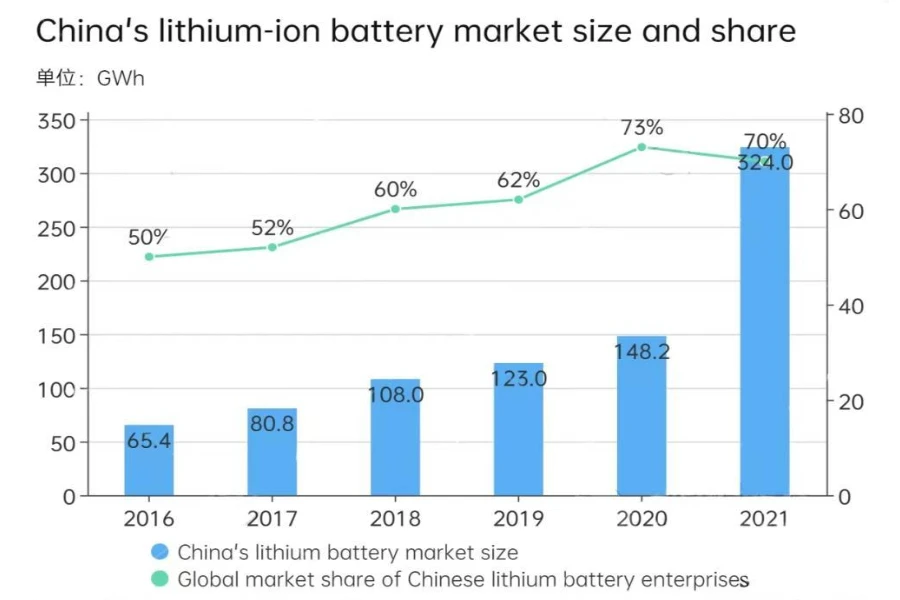

Lithium-ion batteries are now used across various fields, especially in energy, communications, scientific research, aerospace, and emerging industries. According to statistics, in 2016, China’s lithium-ion battery market capacity was 65.4GWh, and over the next five years, grew to reach 324.0GWh in 2021. Between 2016 and 2020, the global market share of Chinese lithium battery companies increased from 50% to 73%. Then, due to the impact of the epidemic, it dropped to 70%.

Lithium-ion battery safety issues

Hazards in the production process

Lithium has extremely active chemical properties, so in the production process, the electrode material and electrolyte of lithium-ion batteries as the internal temperature rises, posing a safety hazard. On the other hand, the use of an electrolyte system, due to the organic solvent decomposition voltage being low, is easy to oxidize, causing the battery to catch fire or even explode if a leakage occurs. In addition, the structure of the electrode material and the choice of diaphragm or electrolyte, etc., may pose additional safety problems.

Security risks during use

During use, lithium-ion batteries also pose safety risks. For example, excessive charging and discharging during use may damage the internal structure of the battery, leading to battery leakage, fires, and other problems. However, with the continuous improvement and maturity of battery management system (BMS) technology, these have been rendered unlikely. In addition, when the lithium-ion battery is squeezed, punctured, or impacted, the internal structure of the battery may be damaged, resulting in similar issues.

Safety risks during recycling

With the large-scale application of lithium-ion batteries, the number of retired batteries is also increasing year by year. During the recycling process of decommissioned batteries, toxic substances such as cobalt and nickel may leak from the batteries, posing a threat to the environment and human health. If the internal structure of the battery does become damaged or the residual electric energy is released, the chance of fire also becomes more likely.

The lithium-ion battery safety performance evaluation index

Below, we’ll take a look at the safety evaluation index of lithium-ion batteries to better understand what the various ratings indicate:

IEC62133 is the safety test standard for lithium-ion batteries and batteries, as well as the safety requirement for testing secondary batteries and batteries containing alkaline or non-acidic electrolytes. It is used to test LiBs used in portable electronics and other applications. IEC62133 addresses chemical and electrical hazards and mechanical issues such as vibration and shock that can pose a threat to consumers and the environment.

UN/DOT38.3 (also known as T1-T8 test and UNST/SG/AC.10/11/Rev.5) covers all transportation safety tests for LIBs, lithium metal batteries, and batteries more generally. The test standard consists of eight tests (T1-T8), all focusing on specific transportation hazards. UN/DOT38.3 is a self-certification standard that does not require independent third-party testing, but the use of third-party testing laboratories is common to reduce the risk of litigation in the event of an accident.

IEC62619 covers the safety standards for secondary lithium batteries and battery packs and specifies the safety application requirements for LIB in electronics and other industrial applications. IEC62619 standard test requirements are suitable for stationary and dynamic applications. Stationary applications include telecommunications, uninterruptible power supplies (UPS), electrical energy storage systems, utility switches, emergency power supplies, and similar applications. Power applications include forklifts, golf carts, automated guided vehicles (AGVs), railways, and ships, and exclude road vehicles.

UL1642 is the UL standard for lithium battery safety, which specifies the standard requirements for primary and secondary lithium batteries used as power sources in electronic products. Technical coverage includes lithium batteries used by professional technicians as well as those used by ordinary users. Lithium batteries used by professional technicians should contain 5 grams or less of lithium metal per unit of battery, while the content in batteries for consumer use should not exceed 1 grams. Batteries that exceed these standards require further inspection and testing to determine whether the battery can be used for its intended purpose. UL1642 does not cover the risk of toxicity due to ingestion of lithium batteries, or exposure to lithium metal due to battery damage or cutting.

UL2580 is the UL battery safety standard for electric vehicles and consists of a number of tests, including: high-current battery short circuiting, battery squeeze, and battery cell squeeze (vertical)

Lithium-ion battery safety improvement strategies

Lithium-ion batteries are widely used in electric vehicles, energy storage systems, consumer electronics, and other products, and their safety is directly related to people’s lives. Battery accidents, such as those caused by thermal runaway, explosions, etc., may lead to serious casualties and property losses.

Some recent developments related to the safety of lithium-ion batteries include:

New technology developments

Introduction of new safety technologies, such as Ecovolta’s electrolytic nickel-plated cold rolled strip made of battery connectors, which automatically disconnects faulty batteries from the rest of the battery pack when a problem arises, helps to avoid accidents. In addition, battery packs’ structural designs are constantly being enhanced via stronger materials and high-strength packaging technology to help them withstand external shocks.

Optimize the battery management systems (BMS), strengthen the real-time monitoring of a battery pack’s status, detecting and handling anomalies in a timely manner. In addition, safer battery materials are constantly being developed and implemented, such as improved compositions in positive electrodes, negative electrodes, and electrolytes so as to reduce the risk of thermal runaway.

Other strategies involve optimizing battery design, such as the use of thin film electrodes, silicon anodes, and other new technologies to improve the thermal stability of the battery. Increasing battery protection devices, such as adding flame retardant materials between positive and negative electrodes, explosion-proof diaphragms, etc., also helps to reduce the impact of short circuiting and thermal runaway.

Scientific research

In general, most lithium-ion batteries consist of polyolefin membranes, liquid organic electrolytes (including vinyl carbonate, diethyl carbonate, and dimethyl carbonate), lithium salts, and positive and negative electrodes. The low thermal stability and flammability of the diaphragm and electrolyte are generally considered to be the main reasons for the combustion and explosion of lithium-ion batteries. Therefore, it is of great significance to improve the safety of lithium-ion batteries from the perspective of the diaphragm and electrolytes. On the one hand, by incorporating phosphate-based liquid flame retardants, researchers can achieve a significant reduction in the flammability of the electrolytes and improve the electrochemical performance of lithium batteries. Phosphorus-oxygen radicals produced at high temperatures can actively trap free radicals produced by combustion to terminate combustion. On the other hand, researchers have developed a significant number of inorganic-based membranes, which are widely used to improve the thermal stability and porosity of the membranes, giving lithium-ion batteries higher safety performance and excellent electrochemical performance.

Sound recycling systems

As we mentioned earlier, with the large-scale application of lithium-ion batteries, the number of retired batteries is also increasing year by year, and the establishment of a sound lithium-ion battery recycling system is of great importance to the rational use of resources, environmental protection, and the promotion of the development of new energy industry. The construction of a decommissioned lithium-ion battery system involves many aspects, including battery storage and transportation management, recycling technology research and development, battery design, establishment of a new source system, publicity, and popularization. For individuals, it is also important to supplement safe recycling guidelines with an understanding on the danger of batteries, and the safe practice of recycling batteries in accordance with regulations.

While lithium-ion batteries do pose certain safety risks during the production, use, and recycling process, their safety can be effectively improved by optimizing the production process, strengthening the use of guidance and supervision, and establishing a sound recycling and treatment system. In the future, with the continuous progress of technology and the application of new materials, it is believed that the safety performance of lithium-ion batteries will be further improved, bringing more convenience and security to our lives.

Battery usage and maintenance recommendations

Correct charging: Use the battery’s original or battery-compliant chargers to charge, and avoid using incompatible chargers. Do not let the battery fully discharge before charging; try to charge when the battery is less than 20%. When charging, choose slow charging, if it’s available, and avoid fast charging to extend the battery life.

Correct use: Avoid running at high load for a long time so as not to cause the battery to overheat. Under normal use, the battery should be maintained at an appropriate temperature, and do not expose the battery to high or low temperatures. In addition, avoid leaving the battery dormant for a long time so as not to cause the battery performance to decline.

Storage: If you do not intend to the battery for an extended period of time, store it in a dry, cool environment (versus one with high or low-temperature conditions). When put into storage, the battery’s power should be at about 50% to help extend battery life.

Avoid excessive charging and discharging: Do not charge the battery to 100% or let it discharge to 0% – try to keep it in the range of 20-80%. Overcharging and discharging can shorten battery life.

Check the battery performance regularly: If you find that the battery’s life is significantly reduced or performance has reduced, check or replace the battery as necessary.

For more trade solutions, industry overviews, and fresh perspectives on business ideas, make sure to subscribe to Alibaba.com Reads.