The winter season presents a significant challenge for farm equipment in terms of failure rates. However, this doesn’t have to be the case. With proper maintenance standards, breakdowns won’t have to occur.

In order to reduce equipment failure during winter, this article will discuss six tips on how to maintain a tractor during winter.

Table of Contents

6 Tips for maintaining a tractor in winter

Final takeaway

6 Tips for maintaining a tractor in winter

Carry out routine maintenance checks

It’s highly recommended to conduct routine maintenance checks throughout winter because it helps spot potential issues. Regular maintenance can extend the tractor’s life and avoid costly repairs down the road.

Here are some routine maintenance checks to perform on a tractor:

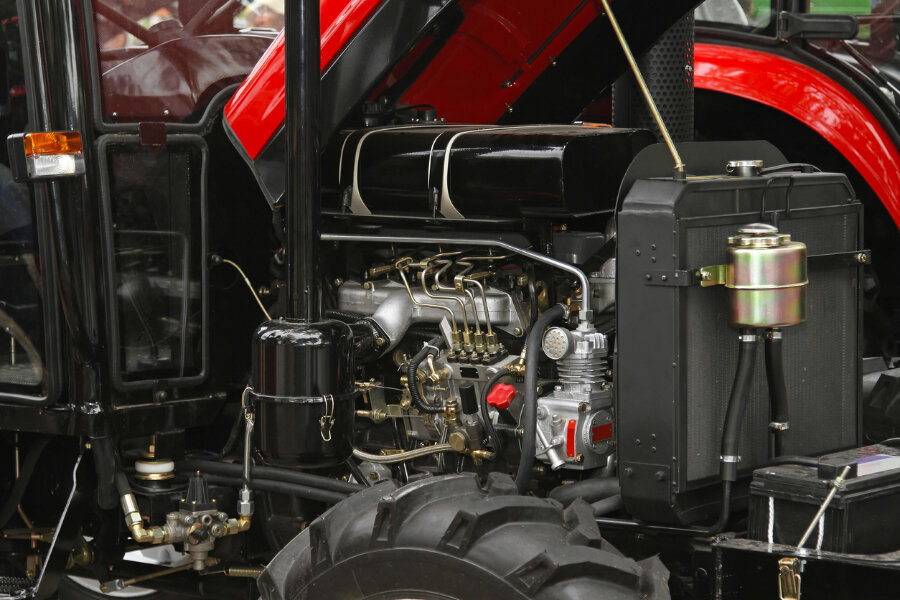

- Check the engine oil level and quality

- Check the coolant level and quality

- Check the air filter

- Check the tires

- Check the battery

- Check the brakes

Check for water or residue

During winter, water and residue build up in tanks, reservoirs, and oil pans. For this reason, it’s important to check and remove any buildup regularly. This can help prevent corrosion and other damage caused by water and residue.

Inspect rubber equipment

During the winter season, the rubber parts on tractors usually experience harsh conditions that causes wear and tear. Components with rubber in tractors include the tires, timing belts, and wire insulators. When it gets to freezing temperatures, rubber equipment becomes brittle and may crack and eventually break, thus affecting the performance of the tractor.

Perform daily checks on the tractor rubber parts and look out for any cracks that may have formed and cut where them off. Avoid running the tractor with cracked rubberand unload anything on the carrier of the tractors to reduce the stress on the tires. That way, a premature service at the dealership will be avoided.

Low temperatures reduce tire pounds per square inch (PSI) and stretch the tires, hence destroying them. So, change timing belts damaged by cold conditions with the best brands. Do the same to insulators and other rubber parts.

If the tractor is not in use, store it in a garage or warehouse that is temperature regulated.

Remove batteries for long-term storage.

During winter, batteries drains faster. Why? Because low-temperature conditions cause the reactions in the battery to slow down. In other words, slow chemical reactions in a battery produces low current. The longer the batteries stay in the cold, the faster they loose juice, and eventually run out.

Hence, the best practise is to disconnect the battery terminals, especially if the tractor won’t be in use for prolonged periods throughout the winter. So, the user can remove the batteries and store them in warm and dry room. For better battery health, charge the batteries with a suitable charger throughout the cold period.

Dirt and debris may settle on connecting points and terminals of the batteries when left for long periods. So, use the correct cleaning equipment toclean up the dirt. That’s the best way to prevent corrosion. DIY tools like toothbrushes will assist in clearing debris.

Let the fuel and engine warm up before putting it to work

If you don’t intend to use the tractor in the winter, it’s ideal to warm its engine and the fuel periodically. Even though a tractor’s engine canstart in the cold weather, allow it to generate the proper amount of heat before putting it to use.

The reason for letting the tractor warm is that it allows the inner components to distribute oil and fuel evenly to every moving part. As a result, the vehicle fluids warms up, and function better.

Fluids freeze in icy weather and may not function properly when in their rigid form. Failure to warm the engine and fuel properly will damage the fuel system components and the pistons.

Stabilize the fuel and replace fuel filters.

In winter, contaminated fuel in the tank breaks down into smaller particles and block holes directing the required diesel/fuel into different parts of the tractor through other lines and pipes. If the diesel in the tank is biodiesel, drain it and add the regular diesel to the tractor.

After the change, let the engine run for a while to circulate the fluids to the respective parts of the tractor. Also, change the old fuel filter that contains impurities for a new one. Use recommended fuel filters for replacement. Avoid poor-quality fuel filters because they won’t serve well in the winter and may possibly destroy the tractor’s components.

Final takeaway

No doubt, tractors need advanced care and maintenance throughout the cold seasons. That way, they can experience an extended life and serve their purpose appropriately. When following the above tips, there will be no cause for alarm in the tractor in winter.