Manufacturers frequently need highly customized and dependable manufacturing processes for their products. Laser technology has advanced to offer high-performance laser welding, engraving, and cutting machines that reduce production time in response to demands from the global industry.

This article will first discuss the dynamic industrial laser machine market before describing the various types of industrial laser machines and trends prevalent in Southeast Asia.

Table of Contents

Overview of the industrial laser machine market in 2023

Types of industrial laser machines

Top industrial laser machine trends in Southeast Asia

Watch these trends

Overview of the industrial laser machine market in 2023

The market for laser cutting machines was valued at USD 6,832.8 billion in 2022, and from 2023 to 2030, it may expand at a compound annual growth rate (CAGR) of 5.5%. The increasing demand for the end-use industry and the rise of automation in the manufacturing sector are expected to boost laser-cutting demand over the forecast period, supporting the expansion of the laser-cutting machine market.

End-use industries such as HVAC, automotive, and electronics widely use these devices to produce high-quality goods efficiently. Due to the precision of the equipment and uniformity of their results, manufacturers are investing in the automation of laser cutting, boosting market growth.

The emergence of fiber laser cutting will further support the market expansion. Many macro-processing tasks requiring millimeter-level accuracy, such as cutting and welding industrial metals, involve using fiber laser cutting devices. The market potential for macro-processing is more significant than micro-processing due to the high demand for laser equipment.

Significant barriers to the market’s expansion include high prices, high power consumption, high cost of the machinery’s parts and maintenance, and release of toxic gasses like phosgene gas.

Types of industrial laser machines

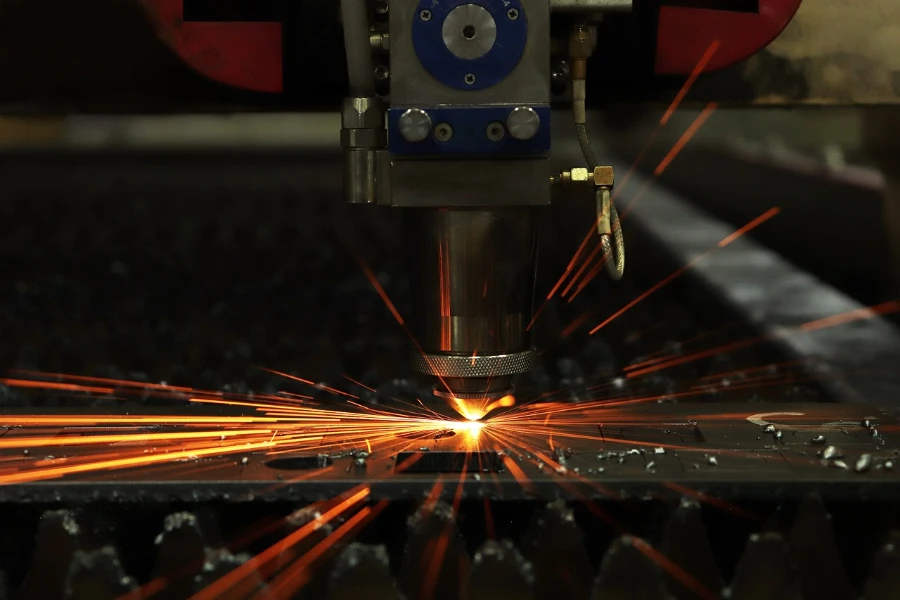

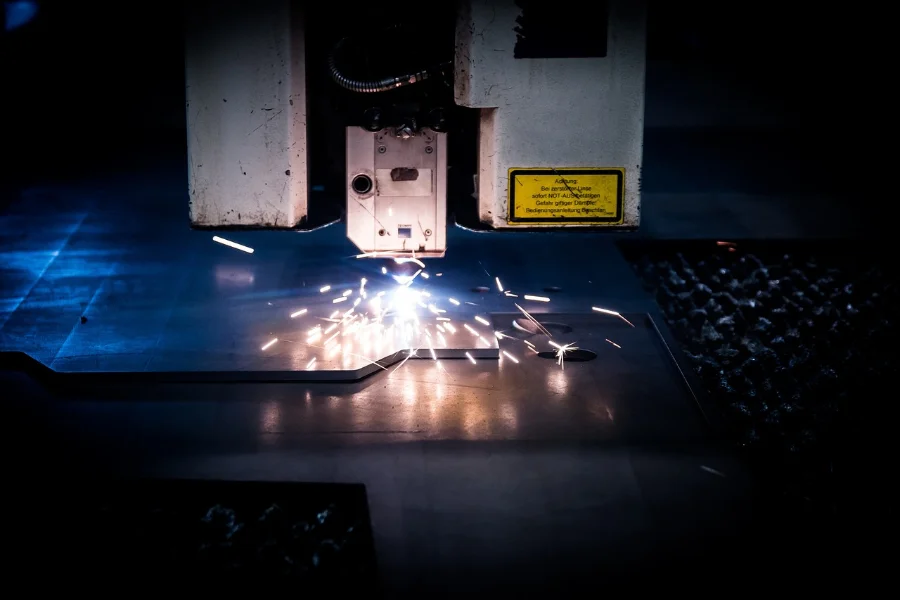

Laser welding machines

One type of laser processing equipment used to weld and cut metal is the laser welder. This workpiece receives energy injection from the laser beam, which melts and solidifies quickly and minimizes distortion after welding.

Lasers have a massive power density. In other words, they can concentrate all their heat right at the seam, improving the condition of the materials around them, compared to conventional welding machines.

Laser welding is incredibly clean and does not need grinding or post-processing. These aesthetic welds also give end-user products a more premium appearance and create pleasing first impressions.

Laser welding is about five to ten times faster than traditional welding techniques, implying a quicker turnaround time and increased productivity, excluding the reduction in post-processing.

The versatility of this machine is second to none. Anything and everything can be welded using various laser setups, including heavy steel plates for the shipping industry, precious metals for jewelry, different metals like aluminum and steel, or copper contacts for electric car batteries. Even welding ceramics, a class of materials known for being difficult to weld, has seen some experimental success.

All of these benefits have a price though. Laser setups can cost twice or even three times more than conventional systems. However, the price per unit decreases, and investment yields dividends if the volume is high.

The market for laser welding machines will expand at a CAGR of 4.73% between 2021 and 2025, reaching USD 373.97 million by the end of the forecast period in terms of usage variety.

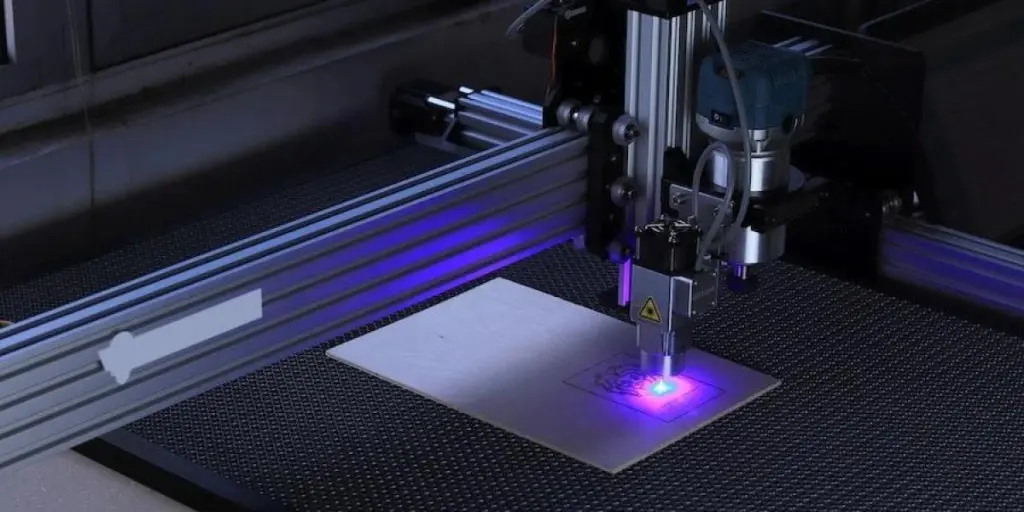

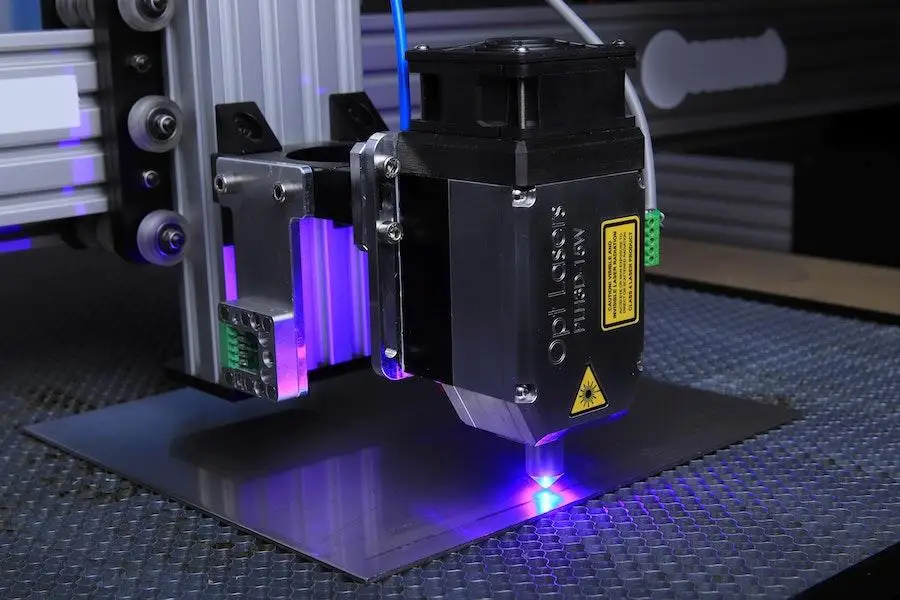

Laser engraving machines

Engineers can now produce characters, numbers, or images without endangering the parts using laser engraving. This method uses focused laser light to create marks that are damage-free and simple to read rather than etching the surface or transmitting ink with a physical tool.

These devices automatically cut and engrave various materials, such as metal, wood, glass, and plastic, with pinpoint accuracy.

It uses no consumables and is therefore green, inexpensive, and energy-efficient compared to consumables like inks and chemicals used in other marking processes, which are costly and negatively impact the environment. Laser marking, instead of labels, provides permanent identification for parts and does not require repeated application.

The non-contact nature of laser marking ensures a clean, minimally contaminated processing environment. The damage-free process only slightly or doesn’t penetrate the material, unlike printing systems that will burn the material down by marking.

Laser engraving also helps manufacturers comply with laws that uphold quality, traceability, and other safety standards, required by federal organizations, the automotive industry, pharmaceuticals, aviation, and other sensitive industries.

According to market analyst predictions, the market for laser engraving is expected to expand at a CAGR of 4.93% from 2017 to 2030.

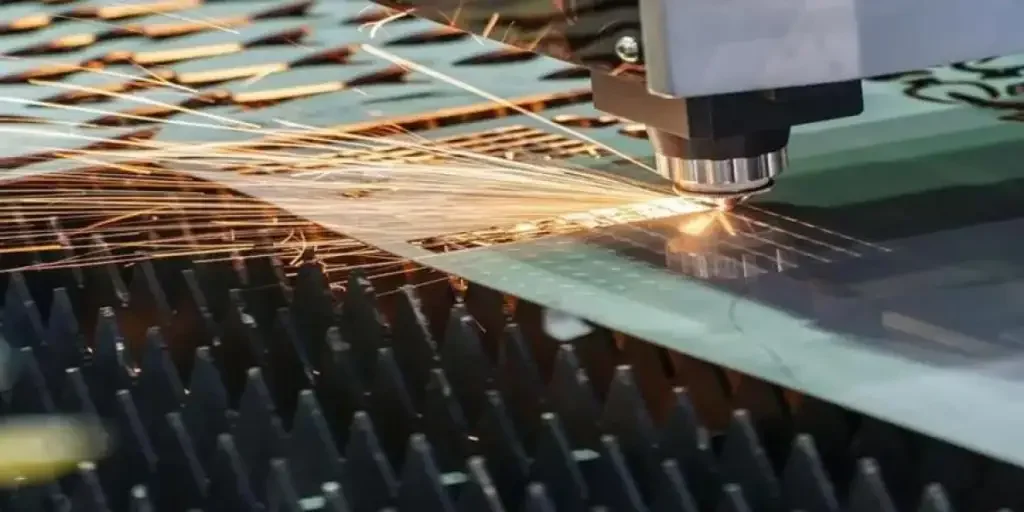

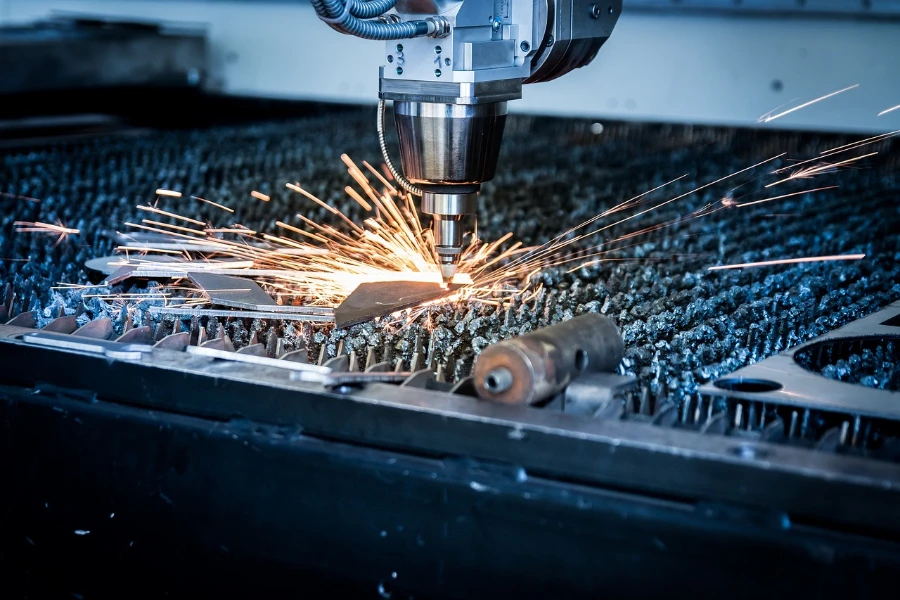

Laser cutting machines

Laser-cutting machines are used in various industries for precise cutting and project design. With the help of a powerful laser beam, this machine can precisely cut or etch a desired design into materials like steel, plastic, or wood.

Laser cutters are versatile. Switching out the tools for different or complex cuts is unnecessary. The same setup can cut numerous shapes from the same material thickness. Naturally, this ability depends on its power.

Laser thermal cutting is faster and more accurate than other thermal cutting techniques, like plasma or flame, cutting up to a thickness of about 10 mm. The laser cutter’s capability ultimately determines the precise advantage point. High precision can be attained without any post-treatment with an accuracy of +/-0.1 mm, and such a high standard typically means that no additional tolerances are needed. Parts that are nearly exact replicas of one another are guaranteed with +/- 0.05 mm.

Modern laser cutting technology is highly automated, requiring little human labor. The final product still benefits significantly from an experienced machine operator. Still, this cutting method is less expensive than others because of the cutting speed and little human effort required.

Between 2020 and 2024, there will be a USD 1.02 billion increase in the market for laser cutting machines, and market growth will pick up speed during this time frame.

Top industrial laser machine trends in Southeast Asia

Automobile industrial laser machine trends

The Southeast Asia automobile industry utilizes laser machines to enhance manufacturing processes, improve efficiency, and achieve higher precision in vehicle production. As a result, the industry is teeming with multiple trends that improve laser machine profitability.

For instance, the Southeast Asia automobile industry uses high-powered lasers to cut different materials relevant to the automotive sector, like metal sheets, composites, and tubes. In addition, it employs powerful laser welding machines to join these metal components and enjoy more precise control.

But that’s not all. Laser-based additive manufacturing processes are also trending in the industry. Types like selective laser melting (SLM) and laser sintering can produce complex automotive parts directly from 3D CAD models.

Laser surface treatment machines, another laser-based trend, can easily modify the surface properties of automotive components. For example, laser texturing can create specific patterns or textures on molds, improving longevity and performance.

Metal processing laser machine market trends

The metal processing industry extensively uses industrial laser machines due to their precision, speed, and versatility. Like other industries, laser technology provides various advantages, including cutting, welding, marking, and engraving.

However, one particular trend that stands out is laser cleaning. These industrial laser machines can easily remove contaminants, oxides, paint, rust, and other coatings from metal surfaces. They also provide a non-contact and environmentally friendly cleaning method without using chemicals or abrasive materials.

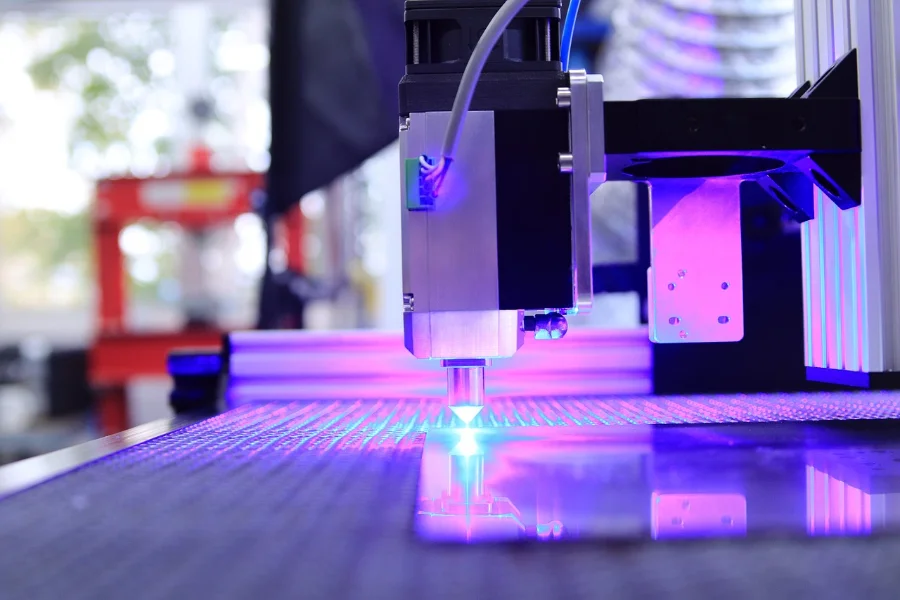

Diode laser machine market trends

Light-emitting diode technology and diode laser technology are both widely used in laser pointers. Although cutting metal with diode lasers was initially challenging, technological advancement forever transformed the industry. A Direct Diode Laser (DDL) device, or injection laser, combines the light from several diodes into a single beam.

Diode lasers can be used on shiny surfaces like copper and aluminum, making them more effective than fiber lasers. The cutting speed is 100% faster because aluminum readily absorbs the wavelength of the diode laser. Additionally, high-powered diode machines can process metals 10–20% faster than fiber lasers. They also offer better edge quality when working with denser materials.

CO2 laser machine market trends

Carbon dioxide (CO2) lasers cut and engrave various materials using a laser beam created from CO2, hence the name. It is one of the most widely used lasers due to its superior cutting power, accuracy, and quick cut speed. The pharmaceutical, food packaging, and electrical industries extensively use CO2 laser technology with metals and numerous non-metals like wood and plastic.

Lasers are an excellent option for cutting thicker materials because they pierce them quickly and produce a smoother surface finish. CO2 lasers are less expensive but use more energy than fiber, which raises the cost of operation. However, this depends on the power.

The laser type, end-use industry, and geography give a better overview of the current state of technology in the global CO2 laser market. The current laser types are transverse flow, sealed-off, and flowing CO2 gas lasers. Of all three, the demand for flowing CO2 gas lasers exhibits high promises for rapid CAGR growth.

Fiber laser machine market trends

Fiber lasers are specialized metal-cutting tools with unmatched speed, accuracy, and repeatability. Usually, they can cut non-ferrous metals and mild and stainless steel. These machines can be set up to cut extremely thick metals and are powered by 500W+ Fiber-Optic laser sources.

Fiber laser machines work best for markings like annealing, etching, and engraving. Due to their minute focal diameter, these lasers are most effective at marking information like numbers, data matrices, and barcodes on metals. Fiber lasers are primarily used for direct part marking to support product traceability and similar identification requirements.

Compared to CO2 lasers, fiber lasers are eco-friendlier, more energy-efficient, with no need for maintenance, and a longer lifespan, implying significant financial savings. Demand for fiber lasers for cleaning applications is increasing. Many industries use laser cleaning equipment to help remove contaminants like paint, oxides, and rust from metals.

Watch these trends

The laser machine market is continually changing due to ongoing technological advancements. Businesses can produce great results on an unprecedented scale thanks to the accuracy and strength of laser machines.

Recent market trends indicate that CO2 and fiber lasers are popular options because of their enhanced performance. Direct diode lasers will have the highest CAGR in the future because of their improved handling capacity, simplicity of servicing, increased reliability, and reduced operating costs.

Sellers can focus on these industrial laser machine trends to boost flexibility, reduce process costs, and make production more efficient.