Inkjet printers remain a crucial asset across consumer and industrial markets, driven by their versatility and precision. Technological advancements, particularly in printhead design and ink management, have propelled these printers into new realms of efficiency and capability.

Understanding market trends and the latest innovations is essential for professional buyers seeking to make informed purchasing decisions. This article provides a detailed exploration of the current market dynamics, cutting-edge technological developments, and the leading models that are shaping the future of the inkjet printer industry. Staying ahead in this rapidly evolving market is vital for maintaining a competitive edge.

Table of Contents

● Understanding the growing inkjet printer market

● Revolutionizing printing: Key innovations in inkjet technology

● Leading models shaping the inkjet printer market

● Conclusion

Understanding the growing inkjet printer market

Market scale and projections

The global inkjet printer market is experiencing robust growth, driven by the increasing demand across various industries such as packaging, textiles, and graphic arts. The market is expected to grow from $7.0 billion in 2023 to $11.6 billion by 2033, at a compound annual growth rate (CAGR) of 5.2%, according to Future Market Insights. This growth is underpinned by the rise in eCommerce, advancements in digital printing technologies, and the expanding use of inkjet printers in industrial applications, which continue to push the market towards higher adoption and innovation.

Market segmentation and shares

The inkjet printer market is segmented into various categories, each catering to different needs and industries. Large format printers are leading the charge, with a significant market share attributed to their widespread use in applications such as vehicle wraps, home décor, and outdoor advertisements. This segment is expected to hold a 52.8% market share during the forecast period. Continuous inkjet technology is another dominant segment, especially popular in coding and marking applications, holding a 53.6% share in the technology type category. The versatility of inkjet printers, from single-function to multifunction and industrial-grade models, allows them to cater to diverse industries including packaging, publishing, and photography, making them an essential tool across the board.

Regional market dynamics

The Asia-Pacific region, particularly China and Japan, is expected to witness significant growth in the inkjet printer market. China, with its cost-effective manufacturing capabilities and high demand for packaging solutions, is projected to achieve a CAGR of 7.7% over the analysis period. Japan is also a key player, with innovations in industries such as foils and films contributing to market expansion. North America and Europe continue to be vital regions, driven by technological advancements and the need for high-quality printing solutions in industrial sectors. These regions are seeing increased demand for large format and industrial inkjet printers, reflecting their strong position in the global market.

Revolutionizing printing: Key innovations in inkjet technology

Advancements in printhead technology

Recent innovations in printhead technology have focused on increasing precision and droplet control, leading to significant improvements in print quality. Microelectromechanical systems (MEMS) printheads are now widely used, featuring nozzles as small as 1 picoliter to deliver ultra-fine droplets. This results in high-resolution prints up to 4800 x 2400 dpi, which are essential for detailed graphic arts and packaging applications. The piezoelectric printheads further enhance precision by using electronic pulses to control droplet formation, allowing for variable droplet sizes that adapt to different print needs. This technology supports higher print speeds without compromising on quality, making it ideal for high-volume environments where both speed and accuracy are crucial.

Breakthroughs in ink management systems

Advanced ink management systems have transformed the efficiency of modern inkjet printers. Newer models now employ recirculating ink systems that continuously circulate ink through the printhead, reducing the risk of clogging and ensuring consistent ink delivery. This innovation not only minimizes downtime for maintenance but also optimizes ink usage, as unused ink is returned to the reservoir instead of being wasted. Thermal inkjet systems have also seen improvements, with integrated sensors that monitor ink viscosity and adjust the heat levels in real-time to maintain optimal printing conditions. These systems allow for extended print runs with fewer interruptions, which is critical in industrial settings where reliability and efficiency directly impact productivity.

Speed and efficiency enhancements

Inkjet printers have seen substantial improvements in speed and efficiency, driven by the integration of high-frequency piezoelectric actuators. These actuators can operate at frequencies up to 30 kHz, enabling faster droplet ejection and higher print speeds. For instance, industrial inkjet printers now achieve print speeds of up to 100 meters per minute, making them competitive with traditional printing methods like offset printing. The development of single-pass print systems, where the printhead spans the entire width of the substrate, has further increased throughput by allowing continuous printing without the need for multiple passes. This technology is particularly beneficial in applications such as textile printing and large-format graphics, where speed and efficiency are paramount.

Adapting to diverse substrates

The ability of inkjet printers to adapt to a wide range of substrates has been enhanced by the development of advanced ink formulations and substrate-specific primers. Modern inkjet inks now include nano-pigments that provide better adhesion and color vibrancy on difficult surfaces like glass and metal. These nano-pigments allow for deeper penetration into porous materials, resulting in more durable prints that are resistant to environmental factors like UV exposure and moisture. Additionally, plasma pretreatment systems have been integrated into some inkjet printers to modify the surface energy of substrates, improving ink adhesion and enabling printing on traditionally challenging materials like ceramics and plastics.

Sustainability and eco-friendly innovations

Sustainability in inkjet printing has been advanced through the use of water-based inks that eliminate the need for harmful solvents. These inks are now formulated with biodegradable compounds, reducing their environmental impact without compromising print quality. Another innovation is the incorporation of LED UV curing systems, which consume less energy compared to traditional mercury vapor lamps and do not produce ozone, making them safer and more environmentally friendly. These curing systems also enable instant drying, which not only speeds up the printing process but also reduces the energy required for drying, contributing to overall energy efficiency. The shift towards closed-loop ink systems has further reduced waste by recycling excess ink back into the system, ensuring that every drop is utilized efficiently.

Leading models shaping the inkjet printer market

Epson EcoTank Pro ET-5850

The Epson EcoTank Pro ET-5850 is a standout in the market due to its exceptional cost-efficiency, making it a top choice for small offices and home use. This model features refillable ink tanks that significantly reduce the long-term cost of ownership by offering ultra-high page yields at a fraction of the cost of traditional cartridge-based printers. The ET-5850 can print up to 7,500 black and white pages or 6,000 color pages on a single refill, making it a reliable workhorse for environments with moderate to high print volumes. Additionally, the printer’s PrecisionCore Heat-Free technology ensures sharp and vibrant prints while maintaining low power consumption, aligning with the growing demand for eco-friendly solutions in office settings.

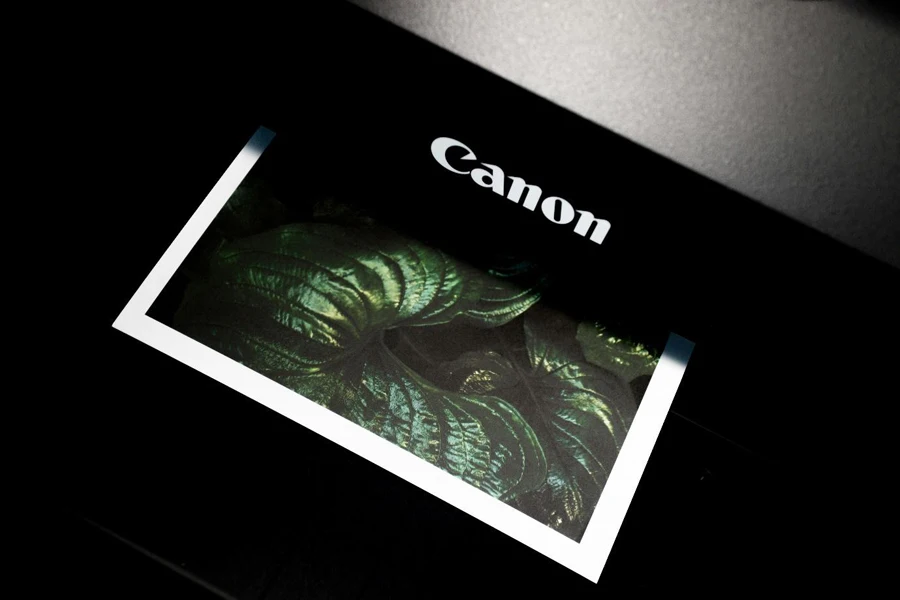

Canon imagePROGRAF PRO-300

For professionals in photography and creative industries, the Canon imagePROGRAF PRO-300 is a leading choice, renowned for its superior photo printing capabilities. This printer uses a 10-ink LUCIA PRO pigment ink system that produces a wide color gamut, delivering prints with exceptional vibrancy and detail. The PRO-300 excels in creating borderless prints up to 13 x 19 inches with smooth gradations and deep blacks, making it ideal for gallery-quality photo prints. The printer also incorporates Canon’s advanced L-COA PRO processing engine, which optimizes print data to ensure accurate color reproduction and precise ink placement. These features make the imagePROGRAF PRO-300 a top performer for photographers who demand the highest print quality.

Brother MFC-J6955DW

The Brother MFC-J6955DW is designed to meet the needs of offices requiring large-format printing capabilities. This all-in-one printer supports tabloid-size (11 x 17 inches) printing and scanning, making it perfect for producing large documents, spreadsheets, and marketing materials. The printer features single-pass duplex scanning and dual paper trays, which increase efficiency by allowing users to handle multiple types of media without constantly swapping paper. Its INKvestment Tank technology ensures low running costs by providing high-yield ink cartridges that last longer, reducing the need for frequent replacements. The MFC-J6955DW’s fast print speeds and robust paper handling capabilities make it a valuable asset for businesses with high-volume printing needs.

Diagraph TJ500 and TJ1000

In the industrial printing sector, the Diagraph TJ500 and TJ1000 models are leading the charge with their advanced features designed for high-speed, high-volume operations. These printers utilize smart print head technology that automatically adjusts to maintain optimal performance, reducing maintenance needs and minimizing downtime. The TJ500 and TJ1000 are capable of printing at speeds of up to 300 feet per minute, making them ideal for demanding environments like packaging and logistics. Their bulk ink systems allow for extended print runs without the need for frequent refills, further enhancing productivity. Additionally, these models offer seamless integration with automated production lines, thanks to their advanced connectivity options including Ethernet/IP and PLC support, making them a cornerstone of modern industrial printing operations.

Epson EcoTank Photo ET-8550

The Epson EcoTank Photo ET-8550 is another model that stands out in the wide-format printing category, especially for home photo printing and creative projects. This model supports borderless printing up to 13 x 19 inches, making it versatile enough for various applications, from large photos to posters and fine art prints. The ET-8550 uses 6-color Claria ET Premium ink, which includes photo black and gray inks for enhanced depth and contrast, particularly in monochrome prints. With its low running costs and high ink yield—up to 2 years’ worth of ink included—the ET-8550 offers a compelling combination of quality and affordability for users who need both high-quality prints and cost efficiency in wide-format printing.

Conclusion

Continuous innovation in inkjet printer technology is essential for sustaining growth and ensuring relevance across diverse markets. The latest advancements, from enhanced printhead precision to eco-friendly ink management systems, demonstrate the industry’s commitment to meeting the evolving needs of both consumers and industries.

Top models like the Epson EcoTank Pro ET-5850 and Canon imagePROGRAF PRO-300 exemplify how cutting-edge features can drive market trends, delivering superior performance, efficiency, and sustainability. As the demand for versatile and high-quality printing solutions grows, these innovations will remain pivotal in shaping the future of the inkjet printer market.