Understand the specific features and advantages of machine laser cleaning, while also discussing how it works and for what it is used most commonly. By reading this blog, it is hoped you will begin to build a coherent understanding of the associated costs of such a process, while perhaps gaining a little knowledge on the subject at the same time.

Table of Contents

What is a laser cleaning machine and how does it work?

How does machine laser cleaning work?

Laser cleaning machine features & advantages

Laser Cleaning Machine Applications

Machine Laser Cleaning Projects & Plans – Application Review

How much does a laser cleaning machine cost?

Almost all mechanical and electronic products require maintenance before assembly and after a period of operation, which usually includes the cleaning of some materials and or components. Traditional mechanical friction cleaning, chemical corrosion cleaning, strong impact cleaning, and high-frequency ultrasonic cleaning are time-consuming without automation, and usually have harmful effects on the environment. Additionally, there is no reliable metric or statistic that measures the cleaning effect of any of these options, diverse though they may be.

In stark contrast to this, laser cleaning has many advantages – as it gives off no pollution (as no consumables are used), has low cost, high efficiency, no first-person contact, and therefore comes with little associated risk of damage. All this, while being easy and intuitive to control; allowing for precision cleaning with high specificity and giving machine laser cleaners the ability to work on potentially dangerous areas. Because of these obvious advantages, machine laser cleaning is considered to be the most reliable and effective solution to the cleaning problems of the future.

What is a laser cleaning machine and how does it work?

A machine laser cleaner is an environmentally friendly cleaning tool that uses nanosecond (or faster) pulsed lasers to irradiate the surface of a workpiece/workplace, so that it may be easily cleaned. This allows almost any surface to instantly absorb the focused energy from the laser, and form a rapidly expanding layer of plasma (which is highly-ionized, unstable gas). Thus, the surface oil, rust, dust, coating, oxide layer, or film will become vaporized and begin to peel away, effectively removing any surface adhesive in the process.

How does machine laser cleaning work?

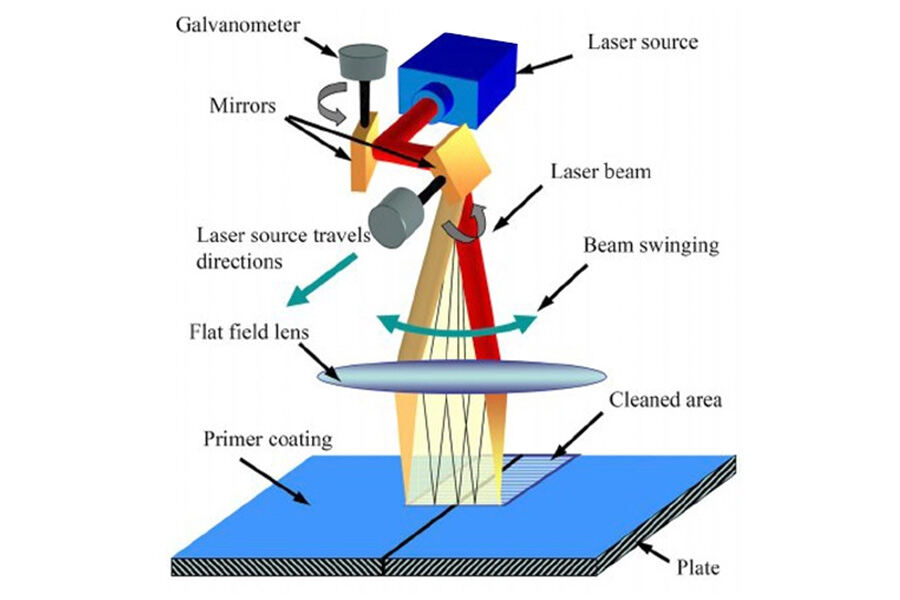

A laser cleaning machine is generally composed of mechanical lasers, a beam transmission shaping unit, an automatic control operating system, a cleaning quality detection/protection unit, and a displacement platform. These are assembled together, forming the architecture of the machine itself, and enabling the unit to function as intended.

Laser cleaning machine features & advantages

At the present time, cleaning methods used widely throughout the cleaning industry include; mechanical cleaning, chemical cleaning, and ultrasonic cleaning. However, their application is greatly limited by the constraints of environmental protection, as well as by requirements from the high-precision market to which they cater. In part because of this fact, the laser cleaning machine has obvious advantages in various industries.

1. Automated assembly line: A laser cleaning machine can be integrated with computer numerical control (CNC) machine tools, or robots, to implement remote control functionality and cleaning. This can help to automate the equipment, allowing it to form a product assembly line and initiate intelligent operations – such as timed and triggered functions, for example.

2. Accurate positioning: Laser cleaning machines use optical fiber to transmit and guide their laser to make it flexible. In addition, they use the built-in scanning galvanometer to control the high-speed movement of the focal point, which is convenient for avoiding parts with specific shapes, such as holes, grooves and other parts that are traditionally difficult to reach. This is another characteristic which puts machine laser cleaning at an advantage over other, older forms of industrial cleaning.

3. Not damaging: Short-term impact from a laser cleaning machine does not heat metal surfaces. This means they usually cause very little damage to any pre-existing substrate (which are the underlying materials of any given surface).

4. Good stability: The pulse laser used by the laser cleaning machine will usually have a long service life, up to 100,000 hours, with stable quality and good reliability. This allows businesses to buy with confidence, knowing that they are likely to be able to use their laser cleaning machines well into the future.

5. No environmental pollution: No chemical cleaning agent is needed and no cleaning waste liquid is generated by machine laser cleaning, which represents a huge attraction for most users. Even the pollutant particles and gas generated during the laser cleaning process can be collected and purified using a laser cleaning machine’s portable exhaust fan – which further aids in the cause of avoiding environmental pollution.

6. Low maintenance cost: Consumables are not used up in any way during the process of machine laser cleaning, and the operating cost is low. In fact, during its later stages, only the lens needs to be cleaned or sometimes replaced entirely, which represents minimal cost. Because of this, the cost of machine laser cleaning maintenance is low, and some might even go so far as to say that it is close to maintenance-free.

Laser Cleaning Machine Applications

Applicable Materials

In an industrial setting, the substances most applicable to machine laser cleaning are divided into two parts; substrate materials and cleaning materials. Substrate mainly includes any surface contamination layer of various metals, semiconductor wafers, ceramics, magnetic materials, plastics, and optical components. Cleaning materials mainly include any chemical substances used for rust removal, paint removal, oil removal, film/oxidation removal, and resin, glue, dust, and slag removal.

Applicable Industries

Research on laser cleaning technology started in the mid-1980s, but it did not really enter industrial production until the early 1990s. Since then, it has achieved good results in various sectors, including mold cleaning, material surface treatment, large-scale equipment, and precision machinery application. In addition, many European countries and cities generally retain a large number of historical relics, ancient buildings and other important antiquities, the maintenance of which requires a high-level of precision. Many churches, castles, universities, museums, sculptures, and many other pieces of art and architecture have hundreds, or even thousands, of years of history inherent within them.

Most Europeans have historically paid great attention to the protection and restoration of these artifacts, as they represent an important part of their history and culture. Thus, laser cleaning technology currently represents the best way to achieve such delicate maintenance – at least, without damaging the valuable objects potentially under your care and financial responsibility. In modern times, machine laser cleaning has been used for the restoration and decontamination of cultural relics, something that scales tremendously.

Other Applicable Fields for Machine Laser Cleaning

- Microelectronics: Machine laser cleaning can be used on semiconductor components, microelectronic devices, memory templates, silicon templates, and other components, to remove particles and oxides.

- Cultural Relic Protection: Stone carvings, bronzes, glass, paper, oil paintings, sheepskin scrolls and murals, etc.

- Mold Cleaning: Rubber molds, composite molds, metal molds, etc.

- Surface Treatment: Hydrophilic treatment, surface roughening, pre-treatment before welding, etc.

- Paint Stripping & Rust Removal: Machine laser cleaners also commonly feature fully automated laser paint and rust removal systems for aircraft, ships, weaponry, bridges, iron towers, etc. This allows for precise paint removal on precision parts, aircraft parts, electrical products (as an alternative to etching), etc.

- Miscellaneous: Urban graffiti, printing rollers, degreasing of industrial parts for precision machinery, cleaning of building exterior walls, nuclear pipelines, and other dangerous industries.

Machine Laser Cleaning Projects & Plans – Application Review

Typical applications of laser cleaning include mold cleaning, industrial rust removal, old paint and film removal, pre-welding and post-welding treatment, de-esterification of precision parts, decontamination and deoxidation of electronic components, and cultural relics cleaning – and that’s just to name a few! Laser cleaning machines are widely used in metallurgy, molds, automobiles, hardware tools, transportation, construction home appliances, machinery, and other associated industries.

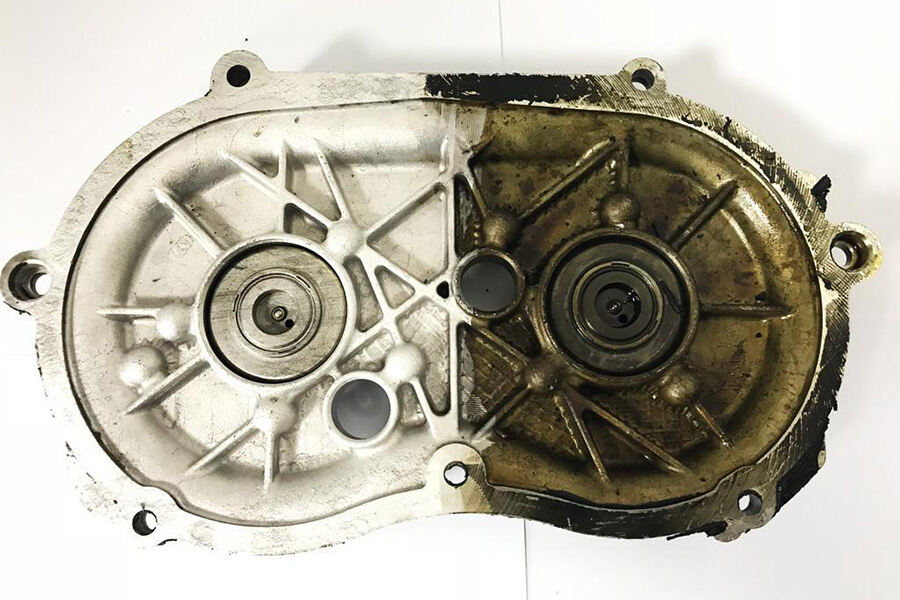

Laser rust removal project (below)

Laser oil dirt cleaning project (below)

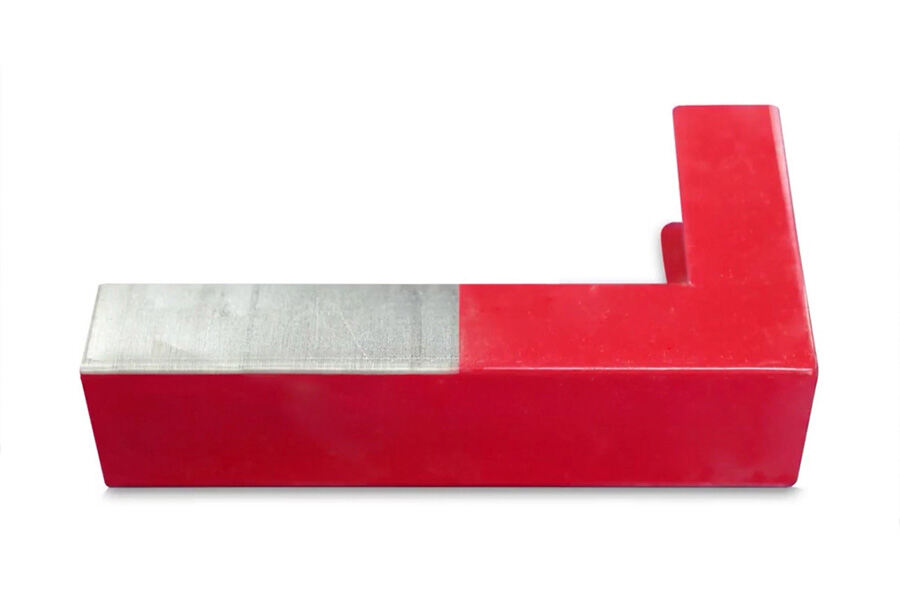

Laser paint stripping project (below)

Laser coating removal project (below)

Laser rubber tire mold cleaning project (below)

Laser stone statue cleaning project (cultural relic restoration) (below)

How much does a laser cleaning machine cost?

Prices for laser cleaning vary depending on your specific application requirements, as well as on any corresponding equipment that must be used during the process. For equipment configuration there is a standard rule: the higher the laser power, the higher the price. It therefore stands to reason that you must first ascertain what levels of laser power will be necessary for a project before price quotes can be accurately produced. Other specifications must be taken into consideration as well, such as the cleaning speed requirements, the thickness of the cleaning material, the material itself and other factors.

Here are a few examples, for reference:

The price of a 1000W laser cleaning machine starts from $10,800.00, and the price of 1500W laser cleaning machines are priced from $13,000.00 to $14,500.00. The cost of 2000W laser cleaners start from $19,800.00, and the highest price is $28,500.00. There is also an automated laser cleaning robot workstation, which adopts a non-standardized design. This robot can adapt to different places, and therefore meet the cleaning needs of different industries and different working conditions accordingly. Its price starts from $62,800.

Source from stylecnc.com

Disclaimer: The information set forth above is provided by stylecnc independentiy of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller andproducts.