New research from Austria has compared different industrial heat-generating techniques and has found that wind or solar-powered heat pumps are the cheapest and most environment-friendly solution.

Image: Johannes Kepler Universität Linz, Sustainable Production and Consumption. CC BY 4.0

A research team at the Johannes Kepler University Linz in Austria has suggested that policymakers subsidize industrial projects using heat pumps to generate steam with a tariff of €3 ($3.2) per gigajoule (GJ). That is the result of a pricing analysis of the environmental impact of different steam techniques, which found heat pumps working with renewable energy to be the least costly. “Taking into account the 43.20 Terajoules (TJ) produced over the lifetime of the plant, a subsidy of €129,600 could be paid,” the researchers stated.

Although the research has focused on wind energy as the renewable source of electricity, co-author Lukas Zeilerbauer told pv magazine that using solar energy should yield very similar results. “PV generally has a higher impact on global warming potential than wind power, but of course still much lower than fossil energy carriers,” he said. “The PV exhibits a shadow price of €1.46 ($1.58), so it is nearly the same as wind.”

In the paper “Life cycle assessment and shadow cost of steam produced by an industrial-sized high-temperature heat pump,” published in Sustainable Production and Consumption, the scientists explained that they utilized Life Cycle Assessments (LCA) to compare different steam-generating techniques used on an industrial scale, including high-temperature heat pumps (HTHPs). Other steam-making techniques include steam-biogas processes, solid biomass processes, and other processes based on natural gas and light fuel oil.

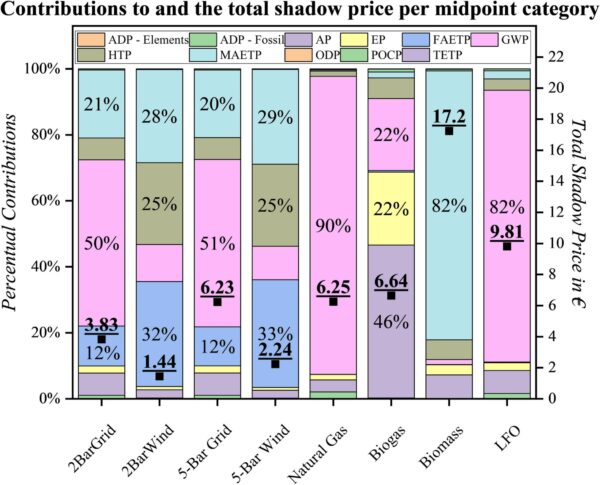

The researchers considered two different scenarios, one in which steam is produced with 2-bar pressure and one with 5-bar pressure. For both scenarios, they took into account use of wind or grid electricity.

“The issue with LCA methods is that they usually consist of more than ten damage categories and hence different results dealing with different areas, and it is difficult to find weighting factors between these very different results,” the research group explained. “However, experts have proposed using monetary values early on. One of those approaches is shadow price, which has the underlying idea that in the end a government, representing its people, has to ‘repair’ environmental damage and is therefore interested in mitigating these costs.”

Not surprisingly, the academics found the combination of heat pumps with wind power has the lowest cost of €1.44 per GJ in the 2-bar scenario, and €2.24 in the 5-bar case. Changing wind energy to the Spanish grid mix has resulted in LCA prices of €3.83 and €6.23 respectively. In comparison, the use of solid biomass for the steam process had an environmental price of €17.2 per GJ, and light fuel oil cost €9.81.

Image: Johannes Kepler Universität Linz, Sustainable Production and Consumption. CC BY 4.0

Looking more in-depth into the environmental effects of the different methods, the research has found the best-case scenario to reduce 98% of greenhouse emissions. However, other environmental measures showed more mixed results, as, for example, toxicity-related results fluctuated between the heat pumps and the benchmarks.

“An unexpected finding was that the working fluid and its leakage did not have a significant contribution to the global warming potential but was almost solely responsible for the ozone depletion potential,” the researchers highlighted. They assumed the use of R134a as the working fluid, as it is the only one with available information in the LCA academic literature.

The HTHP examined in this study was designed for implementation in the pickling line of a steel plant in Spain. It has a nominal heat supply capacity of 250 kW and includes a custom-designed flash tank for steam generation, as well as a circulation pump.

“Although the steam-generating heat pump considered in this study was designed to be implemented in the finishing line of a steel plant, the results of this study can be applied to many other industrial sectors, as steam is a universal heat carrier for many industrial processes,” the academics explained. “This heat pump could be used in any other process that requires low-pressure steam of up to 5 bar.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Source from pv magazine

Disclaimer: The information set forth above is provided by pv-magazine.com independently of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller and products.