In this new era of Industry 4.0 and digital transformation across various fields, particularly manufacturing, smart factory technology has become a key driver of efficiency and competitiveness for manufacturers around the globe.

In this article, we’ll look at this game-changing technology, delving into what smart factories are, their benefits, and the global market outlook. We’ll then dive into the core technologies and hardware associated with smart factories, which will give tech, hardware, and machinery retailers some ideas of lucrative product options that will be worth offering within this growing market.

Table of Contents

What is a smart factory, and what are its benefits?

Overview of the global smart factory market

Core smart factory technologies & related hardware to stock

Add smart factory hardware to your inventory

What is a smart factory, and what are its benefits?

Smart factories are, as the name suggests, factories that are smart. They are a significant departure from traditional manufacturing because they add interconnectivity and intelligence to manufacturing equipment, systems, and processes that would have otherwise been independent and siloed.

Through the synergy of advanced technologies, including artificial intelligence (AI), the Industrial Internet of Things (IoT), big data analytics, and cloud computing, smart factories are able to connect equipment, personnel, and production systems, offering them unparalleled ability to optimize workflows, manage resources, and monitor the entire production process.

This breakthrough of smart factories connecting the physical and digital worlds has brought about significant benefits to manufacturing, including:

- Increased efficiency: The integration of technologies such as sensors and machine learning has enabled factories to better monitor and streamline operations, and this has, in turn, helped to reduce downtime, enhance productivity, and increase output.

- Enhanced quality: The use of technologies that are able to maintain precision, including digital twins and AI-powered quality control systems, has led to greater accuracy on the assembly line and consistent product quality.

- Greater sustainability: Because smart factories enable more efficient management of resources, they can actually reduce waste and energy consumption.

- Improved safety: The predictive analytics and advanced monitoring systems that smart factories employ help to create workplace environments that are safer.

Now, let’s take a look at the market prospects of smart factories and why adding products that serve this market to tech and hardware product portfolios would be a good bet.

Overview of the global smart factory market

IMARC Group’s report on the global smart factory market shows a burgeoning market that is set to be one of the most profitable in the next decade. The report shows that the global smart factory market is set to grow from US $191.6 billion in 2023 to a staggering US $436.4 billion by 2032. This growth is expected to continue at a 9.3% compound annual growth rate (CAGR) over the 2024–2032 forecast period.

Some of the key drivers that are spurring this growth include:

- Growing demand for industrial automation and industrial robots (particularly for manufacturing intricate medical and automotive components, as well as semiconductors)

- Increasing adoption of radio frequency identification (RFID) systems

- Greater focus on environmental responsibility and sustainability

Asia-Pacific has emerged as a key player in the smart factory market as a number of governments in the region have and continue to make significant investments to promote the advancement of smart manufacturing. China and India have adopted national manufacturing policies that will drive up demand for machinery and tools over the next few years.

Core smart factory technologies & related hardware to stock

As market projections point to significant growth in the global smart factory market, an opportunity arises for tech, hardware, and machinery sellers to curate their product portfolios to better serve and potentially profit from this market. In this section, we’ll explore the cutting-edge technologies that are enabling smart manufacturing, along with the top hardware and components that support them and will be worth stocking going forward.

Sensors

Sensors are key components that are driving smart manufacturing as they are deployed on devices and machinery used throughout the manufacturing process. They are able to collect key data at the various manufacturing stages, and this data is used to monitor the entire production process.

For instance, there are sensors used to monitor temperature, position, motion, pressure, applied force, proximity, flow, smoke, images, and much more. These sensors play a crucial role in smart manufacturing as they collect data from the physical world and transmit it to cloud computing platforms.

Cloud computing

Cloud computing in smart manufacturing is the delivery of computing services to store, process, and manage data collected from sensors in the physical factory environment. Advanced cloud technologies enable centralized storage and real-time processing of the data.

Thus, cloud computing is part of the crucial technology foundation where data, applications, and underlying infrastructure exist. There is a range of hardware products that retailers can consider supplying to customers utilizing cloud computing, including servers, network devices, storage devices, as well as power and cooling systems.

Big data analytics

The vast amount of data that is collected, processed, and analyzed throughout the manufacturing process is called “big data.” This data comes from various sources and delivers important information about production rates, machinery performance, quality control metrics, supply chain operations, and much more.

This accumulation of data is what is able to support predictive functions such as predictive maintenance, process improvements, waste reduction, and anomaly detection.

As large amounts of data are being processed, it is necessary for smart factories to have high-capacity big data servers, powerful processors, hardware accelerators, and ultra-large-scale storage systems.

Industrial Internet of Things (IIoT)

The network of interconnected machines, sensors, devices, and processes in the manufacturing environment is what makes up the Industrial Internet of Things. This technology facilitates the interplay between people and machines, with data being the shared language.

IIoT connects personnel with objects on the factory floor, helping them understand the physical condition, performance, and output of factory assets. Retailers can supply the data communication systems that IIoT relies on to enable human-machine exchange, including sensors and actuators.

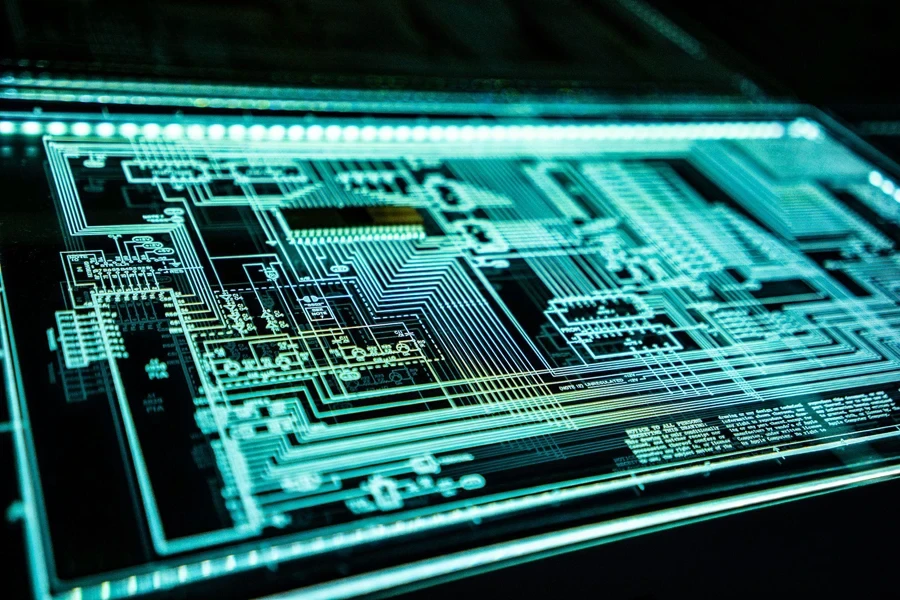

Digital twins

As the name suggests, digital twins involve the creation of virtual replicas of processes or physical objects that are found in factories. This digital model enables factory operators to simulate the performance of these objects or processes in real time, allowing for the analysis and optimization of existing assets and refinement of new products and processes in the virtual environment before they are implemented in the real world.

The key hardware used by this technology is IoT sensors and actuators, as well as network devices such as edge servers, routers, and IoT gateways.

Artificial intelligence (AI) and machine learning (ML)

We cannot talk about smart manufacturing without talking about artificial intelligence. AI is a technology that enables machines, particularly computer systems, to simulate human intelligence processes. This includes learning from the collected data, reasoning around the data, and self-correcting in the physical world.

Machine learning is a subset of AI that enables the systems within the smart factory to learn from their experience and make improvements without being programmed.

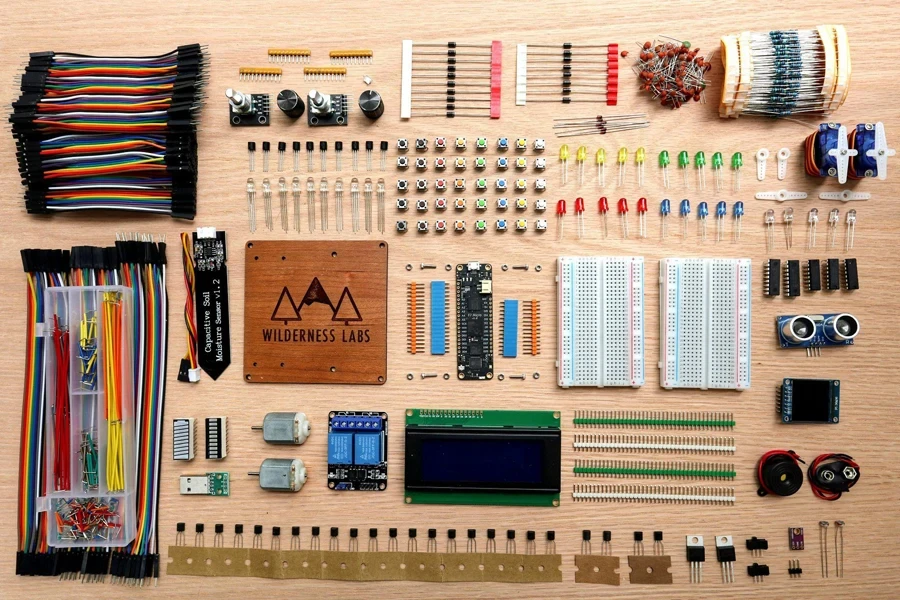

Retailers can add the specialized computer hardware used to execute AI and ML to their inventory, including microcontrollers, sensors, boards, and chips.

Automation and robotics

When people think of smart factories, automation and robotics are likely to come to mind first. Automation is the process of using technology to perform repetitive tasks that would have otherwise been performed by humans, such as packaging and assembly.

These automated tasks can be either virtual or physical, which is where robots come in. Robots are capable of performing certain repetitive tasks with a great amount of speed and accuracy. This, of course, leads to significant improvements in operational efficiency and reductions in labor costs.

To support these functions, retailers can supply common components found in robots, such as sensors, CPUs, actuators, motors, connectors, and effectors.

Add smart factory hardware to your inventory

As has been explored, smart factories come with a plethora of technologies, systems, and hardware that support them. The projections for the global smart factory market show that this market is poised to expand, and with that, demand for different technologies and connected hardware will also increase.

Tech, hardware, and machinery retailers can leverage this projected market expansion and update their product offerings to include any of the vast array of supporting hardware that will be required in the growing industry.

Below is a snapshot of the various product requirements for the core technologies:

- Sensors: Temperature sensors, position sensors, motion sensors, pressure sensors, flow sensors, and image sensors.

- Cloud computing: Servers, network devices, storage devices, and power and cooling systems.

- Big data analytics: Servers, processors, hardware accelerators, storage systems.

- Industrial Internet of Things: Sensors and actuators.

- Digital twins: IoT sensors, actuators, edge servers, routers, and IoT gateways.

- Artificial intelligence and machine learning: Microcontrollers, sensors, boards, and chips.

- Automation and robotics: Sensors, CPUs, actuators, motors, connectors, and effectors.

To explore a wide variety of hardware suppliers, visit Alibaba.com and update your inventory with the wide product options on offer.