Table of Contents

Introduction

Market Overview

Things to consider when selecting smart robots

Top smart robot models and their features

Conclusion

Introduction

Smart robots are transforming industries by integrating advanced AI and automation to achieve high precision, speed, and adaptability. These intelligent machines now handle complex tasks across sectors like manufacturing, logistics, and healthcare, boosting operational efficiency and lowering costs. Equipped with sensors and machine learning, they can interpret environments and make decisions in real-time, enhancing productivity even in unpredictable settings. Collaborative robots, or cobots, work safely alongside human workers, taking over repetitive or hazardous duties. As businesses strive for greater flexibility, smart robots are emerging as essential assets in the modern industrial landscape.

Market Overview

The global smart robot market reached $12.4 billion in 2023, with projections indicating a rise to $47.7 billion by 2032, driven by a compound annual growth rate (CAGR) of 15.6%, according to IMARC Group. This growth is largely fueled by advancements in artificial intelligence (AI) and machine learning (ML), enabling robots to handle complex tasks autonomously across industries. North America leads the market, accounting for approximately 35% of the global share, with high investments in automation contributing to adoption rates in sectors like manufacturing, logistics, and healthcare, where precision and efficiency are critical.

Demand for service robots is expanding rapidly in healthcare, hospitality, and retail, and the service segment could account for nearly 25% of the market by 2030. According to IDC, key regions are responding to rising labor costs and shortages, especially in Asia-Pacific, where the automation sector grew by around 20% last year. Although high initial costs and integration challenges remain obstacles, by 2025, 40% of major manufacturers are expected to connect at least 30% of their robots to cloud platforms, enabling data-driven, adaptable robotic solutions worldwide.

Things to consider when selecting smart robots

When selecting smart robots, it’s essential to ensure that the model chosen matches the specific application requirements of the environment, whether for assembly, logistics, healthcare, or customer service roles. Robots for manufacturing, for instance, need precise assembly capabilities, while logistics settings benefit from robots capable of efficient sorting and mobility. According to IMARC Group, assembling and disassembling tasks dominate in industrial robotics due to the precision required, making these functions critical in manufacturing and electronics sectors. Additionally, smart robots for customer service in retail or healthcare environments are increasingly equipped with advanced sensory technology to enhance interaction quality and service accuracy.

Considering the robot type and its specific features is key to maximizing efficiency. Autonomous Mobile Robots (AMRs) are ideal for dynamic environments like warehouses and healthcare facilities, where they can navigate autonomously, making real-time decisions based on sensory input. Collaborative robots, or cobots, designed for human proximity and repetitive tasks, are valued for their safety and ease of use in manufacturing settings. According to Fronetics, the trend toward using cobots is growing, particularly in industries where human-robot collaboration improves workflow without compromising safety. For outdoor or challenging terrains, Unmanned Autonomous Vehicles (UAVs) offer flexibility and advanced mobility, ideal for roles in agriculture, disaster response, and field inspection, where adaptability to changing conditions is essential.

A smart robot’s technology stack significantly influences its performance and adaptability. Robots equipped with artificial intelligence (AI) and machine learning (ML) use data-driven insights and sensor technology to navigate complex environments, making adjustments in real-time. IMARC Group reports that AI-integrated robots are increasingly employed in sectors requiring precise control and adaptation, from medical diagnostics to autonomous driving. Additionally, cloud connectivity options are becoming critical as robots with cloud integration allow for scalable data processing and storage, enabling updates and remote adjustments, which enhance the flexibility and usability of smart robotic systems.

Investing in smart robots also requires evaluating the return on investment (ROI), considering both initial costs and long-term benefits. According to Happiest Minds, organizations integrating robots within their enterprise systems, such as ERP and warehouse management systems, report productivity gains of up to 40%. These integrations not only reduce labor costs over time but also streamline operations, particularly in manufacturing and logistics, by improving accuracy and reducing downtime.

Top smart robot models and their features

Leading Autonomous Mobile Robots (AMRs), such as those from Fetch Robotics, have become essential in sectors like warehousing, healthcare, and delivery due to their capability to navigate complex spaces autonomously. Equipped with advanced sensor technology, these robots handle tasks like transporting goods in warehouses and delivering medical supplies in hospitals, adapting efficiently to dynamic environments. According to Happiest Minds, AMRs use real-time data from sensors and AI-powered systems to make on-the-fly decisions, maximizing efficiency in logistics operations and reducing manual handling needs.

In manufacturing environments where precision is critical, articulated robots from KUKA and Fanuc excel in tasks such as welding, assembly, and painting. These robots mimic human arm movements with multiple joint rotations, allowing for a wide range of motion that is ideal for industrial applications. According to IMARC Group, articulated robots play a dominant role in the automotive sector, with their capacity to handle repetitive tasks with high accuracy, thereby reducing operational errors and labor costs.

Hybrid robots combine multiple functionalities to support versatile, multi-environment operations. For instance, agricultural applications benefit from hybrid drone-robot models that can conduct aerial crop assessments and ground-level tasks, such as harvesting or soil monitoring. These adaptable hybrid robots are critical for industries that require flexible automation solutions capable of performing various functions within a single unit, especially in sectors where environmental adaptability is essential.

Collaborative robots, or cobots, like those from Universal Robots and Yaskawa, are designed to work safely alongside humans, enhancing productivity in roles that involve repetitive or ergonomically challenging tasks. Cobots are increasingly popular in manufacturing and assembly lines, where they support human workers by handling physical tasks that can lead to strain or fatigue. According to Fronetics, the safety-focused design of cobots allows them to operate in close proximity to humans without compromising efficiency, making them an integral component of modern, human-centric manufacturing environments.

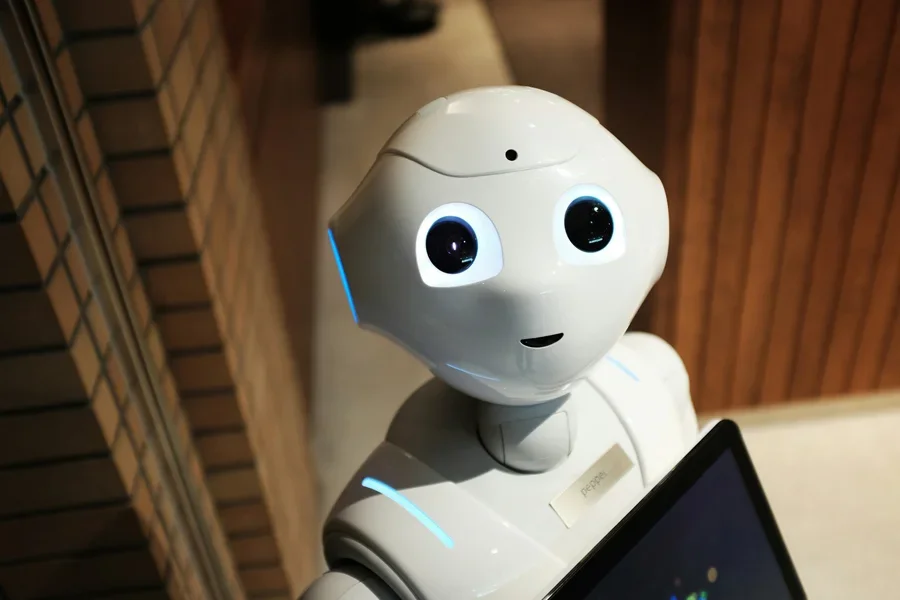

Humanoid robots, such as SoftBank’s Pepper, bring value to customer service, education, and hospitality. With the ability to interact naturally with people, humanoid robots are being deployed in stores, schools, and healthcare facilities to provide assistance, answer questions, or guide individuals through processes. These robots use advanced sensors, speech recognition, and machine learning to respond appropriately to human cues, fostering smoother interactions in customer-facing roles.

Conclusion

Smart robots continue to transform industries, offering businesses a powerful combination of precision, adaptability, and operational efficiency. By carefully selecting robots that align with their specific applications and budget constraints, companies can streamline processes, enhance productivity, and reduce labor costs. As technology advances, the flexibility of smart robots to adapt and learn from real-time environments provides businesses with a valuable edge in meeting dynamic industry demands, ensuring both short-term efficiency gains and long-term growth potential.