Rectifiers convert AC to DC, powering devices and charging batteries. They also play a key role in radio signal detection through technologies like vacuum tubes, silicon diodes, and mercury arcs.

This article will delve into the global market share and development trends of rectifiers, as well as breaking down basic parameters and comparing different types of rectifiers. This will offer you strategic insights that will help you to select the best rectifiers for your buyers in 2025.

Table of Contents

What’s the current global market outlook for rectifiers?

What are the key parameters of rectifiers you should know?

What are the common types of rectifiers and how do they differ?

Latest rectifier market trends you need to know

How can you select the right rectifier for your needs?

Summing Up

What’s the current global market outlook for rectifiers?

The rectifier industry has made important progress in technological development. In recent years, the continuous improvement of semiconductor materials and component technology has significantly improved rectifiers in terms of efficiency, power density, size, and weight. In addition, the application of intelligent control technology also makes the use of rectifiers more convenient and safer.

The global electromagnetic relays market is projected to reach US$ 2177.8 million in 2029, increasing from US$ 1623 million in 2022, with a compound annual growth rate (CAGR) of 4.2% during the period of 2023 to 2029.

The market demand for the rectifier industry is constantly growing. With the rapid development of the new energy industry, especially the large-scale application of distributed energy, such as solar energy and wind energy, the demand for rectifiers as core components is also increasing. At the same time, the demand for rectifiers in industrial automation, transportation, healthcare, and other fields is also increasing year by year.

What are the key parameters of rectifiers you should know?

The basic parameters of rectifiers are crucial, serving as key selection criteria in procurement decisions. In this part, we’ll explore them in depth.

- Output power: The DC output power of the rectifier reflects the ability of the rectifier to convert alternating current to direct current, which is an important index to evaluate the performance of the rectifier.

- Input voltage: The input voltage determines the range of alternating current that the rectifier can handle and is an important consideration when selecting a rectifier.

- Output voltage: The DC voltage output by the rectifier determines the operating voltage that the DC load can obtain.

- Certification: Passed the CE standard

- Size: Due to the large number of internal components and large heat dissipation requirements, the physical size of the high-power rectifier will be relatively large. In contrast, low-power rectifiers, such as those in mobile phone chargers, are relatively small in physical size.

- Efficiency: The ratio of the output current to the input current of the rectifier reflects the conversion efficiency of the rectifier. Efficiency is one of the critical indicators used to evaluate the performance of the rectifier. The high efficiency means less energy loss.

What are the common types of rectifiers and how do they differ?

Rectifiers vary widely in design and application—from controlled and non-controllable types to specialized high-frequency and high-voltage models. Below, you will look at the types of rectifiers and power conversions classified by different categories in detail.

1. Classification by control

Controlled rectifier

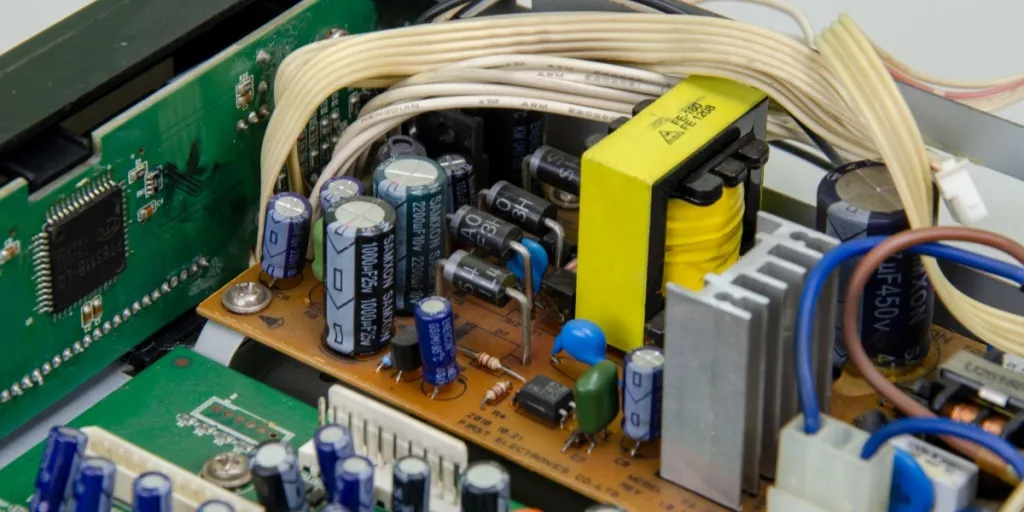

Its output current and voltage can be adjusted, usually using a thyristor, field effect tube, capacitor diode, and other components. The adjustable rectifier has the characteristics of high output precision, high efficiency, and good stability.

In operation, the adjustable rectifier needs to be controlled by the control circuit, through the control circuit, to adjust the trigger pulse of a specific component and then control the output current and voltage of the circuit. It is widely used in the field of induction cookers, motor control, communication equipment power supply, electric vehicle chargers, and so on.

Non-controllable rectifier (also called direct fixed rectifier)

Its output current and voltage are fixed and cannot be adjusted. It is usually composed of diodes, transistors, and other components, of which the main role of the diode is independent rectification, alternating current into one-way pulsating direct current, and the transistor is mainly used for power conversion and voltage stabilization circuit.

The direct fixed rectifier has the characteristics of simple structure, low cost, and high reliability. It is widely used in small circuits (such as LED lights, digital products, low-end power supplies, etc.) and high-frequency communication equipment.

2. Classification by circuit structure

Single-phase rectifier

Suitable for single-phase AC power supplies, usually consisting of a set of diodes. The most common is the single-phase bridge rectifier, which consists of four diodes and is able to convert the negative half-cycle of the input signal into a positive half-cycle output.

Three-phase rectifier

Suitable for a three-phase AC power supply, usually consisting of six diodes or three thyristors. They convert the input three-phase AC signal into a DC signal.

In a three-phase rectifier compared with a single-phase rectifier, in the case of the same input voltage, the output DC voltage is higher, and the current fluctuation is smaller, suitable for the need for large current, high voltage occasions.

3. Classification by application scenario

Universal rectifier (also known as hybrid rectifier)

This combines a direct fixed rectifier and an adjustable rectifier. General-purpose rectifiers generally adopt a hybrid structure, using diodes, transistors, thyristors, and other components.

The general-purpose rectifier has the characteristics of simple structure, high reliability, and low cost. It is widely used in the field of power supply, welding machines, power tools, and so on.

4. Other special types of rectifiers

High-frequency rectifier

Gold doping, meeting the needs of high-frequency work, is usually used in silicon rectifiers to shorten the life of injected minority carriers and reduce recovery time. This rectifier performs well in high-frequency circuits.

High-voltage rectifier

The high-voltage rectifier device is often used in high-voltage silicon stacks. It is composed of a plurality of rectifier device cores in series. The reverse voltage is determined by the pressure resistance of the tube core and the number of series tubes, and the maximum voltage can reach hundreds of kV.

Avalanche rectifier

When the reverse voltage exceeds the allowable peak, uniform avalanche breakdown occurs on the entire PN junction, and the device can work at high voltage and large current so that it can withstand considerable reverse surge power. This rectifier is suitable for applications where high reverse voltage and surge power are required.

Latest rectifier market trends you need to know

Understanding the latest trends in the rectifier industry is crucial for staying ahead in a rapidly evolving market, ensuring you make informed decisions before making an investment.

1. Rapid development of the new energy industry

The rectifier industry outlook analysis mentioned that with the increased demand for renewable energy globally, especially the large-scale application of new energy such as solar and wind energy, the demand for rectifiers in inverters and battery charging is also growing. Rectifiers, as one of the key equipment, have huge market potential in the new energy field.

2. Expansion of the electric vehicle market

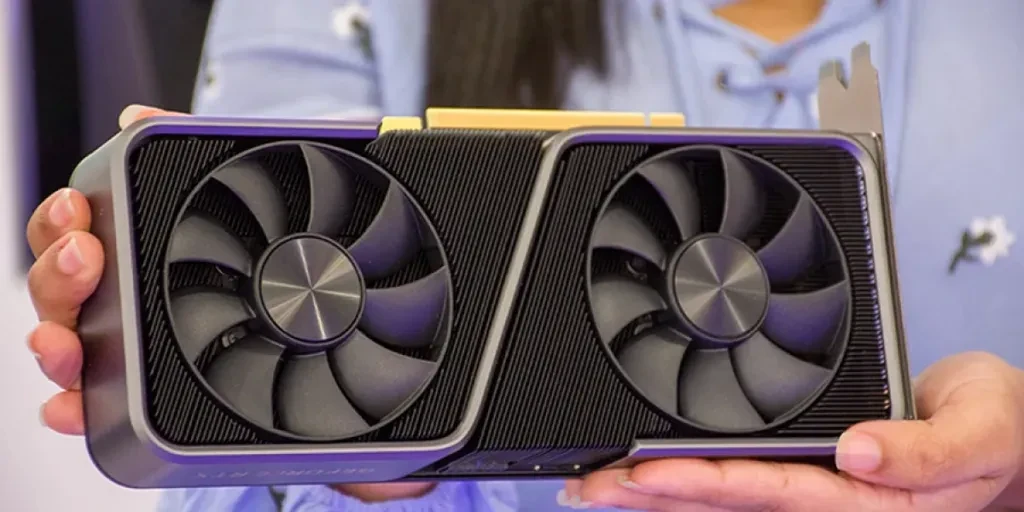

With the rapid growth of the electric vehicle market, rectifiers play a crucial role in electric vehicles, converting alternating current into direct current to feed electric vehicle batteries. With the increase in sales of electric vehicles, the rectifier market will also be further expanded.

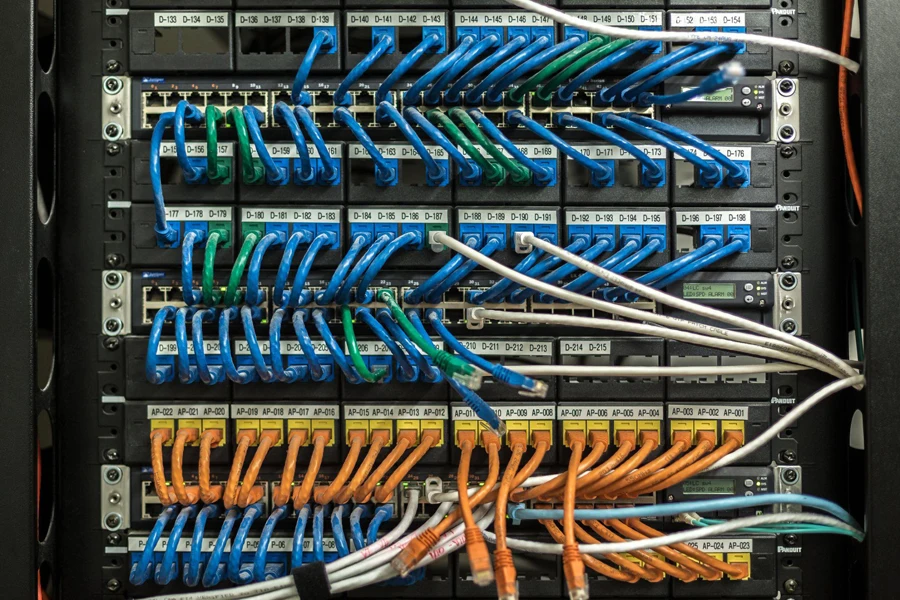

3. Drive for industrial automation

The development of industrial automation provides a continuous demand for the rectifier market. Rectifiers are widely used in industrial control systems to drive motors, control voltage and current, etc. With the increase of industrial automation and the acceleration of factory intelligence, the demand for rectifiers will continue to grow.

4. Popularization of 5G communication technology

With the commercialization of 5G communication technology, the demand for rectifiers in 5G base stations will also increase rapidly. Rectifiers can convert alternating current to direct current to provide a stable power supply for 5G base stations. With the popularity of 5G networks, the rectifier market will be further expanded.

5. Application of new materials and new technologies

The continuous development of new semiconductor materials and component technologies provides greater room for improvement in the efficiency and performance of rectifiers. For example, the application of wide band gap semiconductor materials can improve the efficiency and reliability of rectifiers. In addition, the application of intelligent control technology will further improve the rectifier’s performance and function.

There are some challenges in the development of the rectifier industry. The competition in the rectifier industry is fierce, and the market share is dispersed. Rectifiers have various applications, but the needs of different fields vary greatly, requiring targeted design and manufacturing. There are still some technical problems in the research and development of rectifiers in the application of high power and high frequency.

How can you select the right rectifier for your needs?

The above sections have provided essential information about rectifiers for you to make more informed purchasing decisions. To select the most suitable rectifier based on your operational needs, refer to the following process.

First, understand the electrical factor is vital:

- Power requirements: Different devices have different requirements for the power of the rectifier. Ensure that the power of the rectifier meets the device’s requirements.

- Voltage and current requirements: Understand the DC voltage and current range required by the device and make sure the output voltage and current are within the range required by the device.

Second, know the external conditions:

- Working environment: Consider the environmental conditions in which the rectifier works, such as temperature, humidity, vibration, etc.

Last, pay attention to performance:

- Efficiency: Choose more efficient rectifiers to reduce losses.

Summing up

The rectifier market is evolving quickly with new technology and rising demand. Staying updated on trends and key factors is essential for making smart purchasing decisions. By choosing the right rectifiers, you can ensure good performance and reliability, helping your business succeed.