As the demand for efficient, compact electronics grows, switching power supplies are evolving rapidly. This article delves into the key advancements, applications, and market impact of this technology, along with essential tips for selecting the right power supply based on critical parameters like efficiency and output voltage.

Table of Contents

Intro to switching power supplies

Market size and growth points

Common categories and parameters worth noting

Latest developments

Conclusion

Intro to switching power supplies

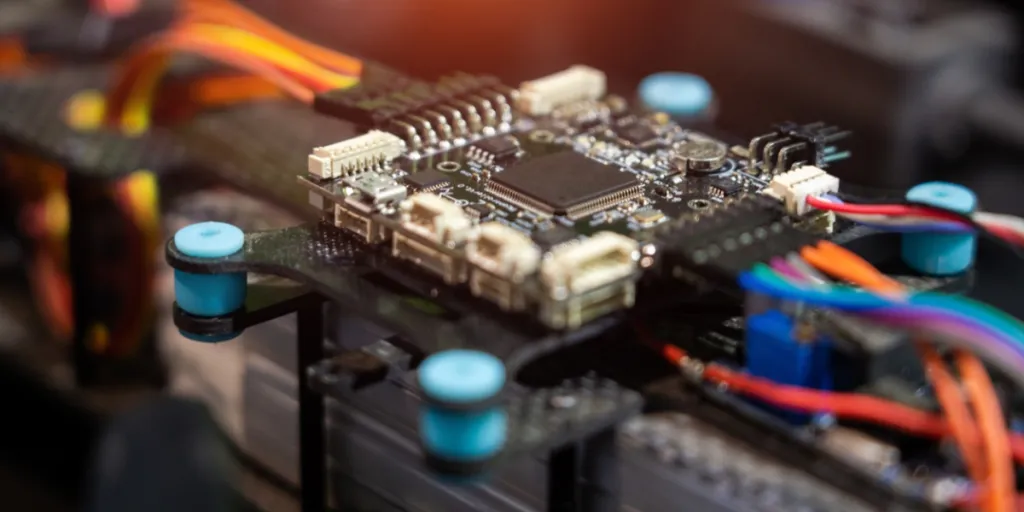

Before the advent of the mobile phone, the revolution from linear power supply to switching power supply took place in the development of the personal computer. Many people understand the computer (PC) itself and know its processor model and memory size. But some may not know anything about its power supply. The earliest PCS used linear power supplies.

In just a few decades, switching power supply technology has been turned on its head, and the great progress of semiconductor devices is behind it. Modern power technology is developing in the direction of:

- Greening

- Miniaturization

- Modularization

- Intelligence

- Modularization and intelligence

- Digitalization and diversification

With the characteristics of low power consumption, low pollution, low current, high efficiency, and high integration gradually becoming the mainstream, power technology also depends on the development of electronic components and integrated circuits. The new switching power supply integrates the power switch tube and various output protection modules to reduce the volume further.

Market size and growth points

According to Hengzhou Chengshi survey statistics, the size of the global switching power supply market in 2022 is about USD 29.56 billion. The future is expected to maintain a steady growth trend, and the market size will be close to USD 46.72 billion by 2032, with a compound annual growth rate (CAGR) of 4.7% during the forecast period.

The main manufacturers of global switching power supply are DELTA, Lite-On Technology, Salcomp, Cosel, etc. The top three manufacturers in the world occupy nearly 20% of the market share. The global switching power supply market has shown steady growth in recent years.

This growth is mainly attributed to the need for miniaturization, efficiency, and intelligence of electronic devices and the rapid development of emerging areas such as renewable energy systems and electric vehicles.

The switching power supply market is expected to continue to expand in the next few years with the popularization of technologies such as the Internet of Things, 5G communication, and artificial intelligence.

Common categories and parameters worth noting

To fully understand the switching power supply, you need to start by examining its electrical parameters, application limitations, and related indicators to analyze and understand its full picture. This way provides precise and professional support for our use or procurement needs. Here’s an example to help us understand better:

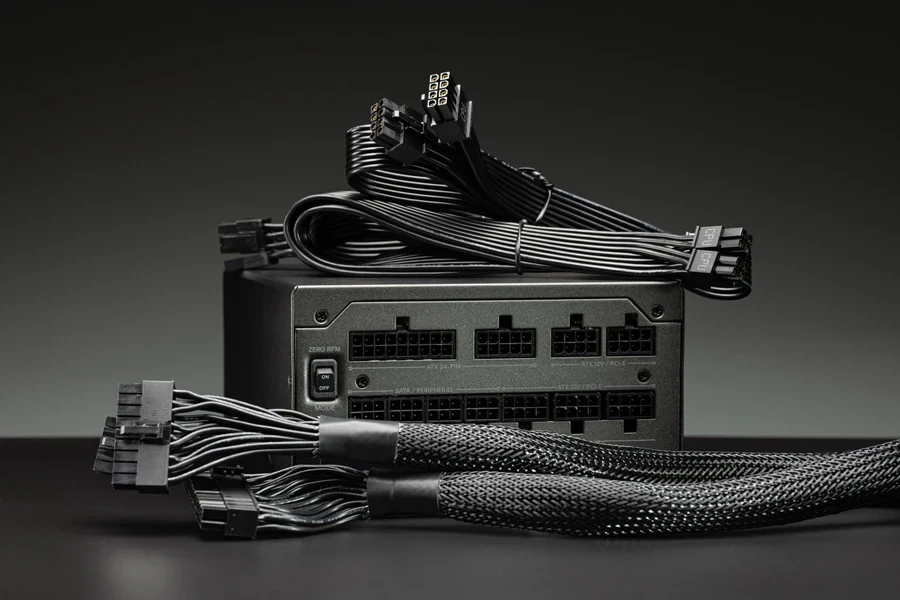

Electrical parameters of switching power supply

Input voltage range

The minimum and maximum values of the input voltage are accepted by the switching power supply. This range usually depends on the power supply design and the application environment. For AC, the input voltage ranges from 85-264V.

Output voltage

The voltage is provided by the switching power supply to the load. Match the demands of the load (12v).

Output current

The current value provided by the switching power supply to the load during normal operation. (20A).

Conversion efficiency

The efficiency with which a switching power supply converts energy from an input power supply into energy from an output power supply. The higher the conversion efficiency, the smaller the energy loss and the lower the heat output of the power supply (> 85%).

Frequency

The rate at which a switching power supply converts an input voltage to an output voltage, usually in kilohertz (kHz). The higher the frequency, the smaller the switching loss, but the design difficulty and cost of the switching power supply will also increase (60K – 90KHZ).

Ripples and noise

Undesirable small fluctuations (ripples) and high-frequency noise in the output voltage. It is especially important for precision electronic equipment because it can affect the performance of the equipment (<80MV).

Cooling method: Air cooling

Protection function

It includes over-current protection (OCP), over-voltage protection (OVP), over-temperature protection (OTP), and short circuit protection (SCP) to protect power and load equipment from damage.

Switching power supply-related application limit parameters

Load capacity

The maximum power or current of a load that a switching power supply can support. Exceeding this limit may cause overheating or damage to the power supply.

Safety certifications

The switching power supply must comply with safety standards and certifications, such as UL, CE, RoHS, etc. These certifications ensure the safety and environmental protection of the power supply.

So many parameters also form a considerable number of switching power supply types, including:

Classification by working principle

Pulse width modulation (PWM) switching power supply: The output voltage is controlled by adjusting the on-time (pulse width) of the switching element.

Pulse frequency modulation (PFM) switching power supply: The output voltage is controlled by adjusting the frequency of the switching element.

Hybrid switching power supply: Combines the characteristics of both PWM and PFM technologies.

Resonant switching power supply: The use of resonant circuits to achieve switching action, usually switching components work under zero voltage or zero current conditions.

Classification by topology

Forward converter: The input voltage is directly converted to the output voltage, often used for Buck conversion.

Reverse converter: The input voltage is lower than the output voltage and is often used for Boost conversions.

Push-Pull converter: Uses two switching elements to work alternately, increasing efficiency and output power.

Full-Bridge converter: Uses four switching elements for high-power applications.

Half-Bridge converter: Uses two switching elements for medium power applications.

Single-tube converter: Uses a single switching element for low-power applications.

Classification by application field

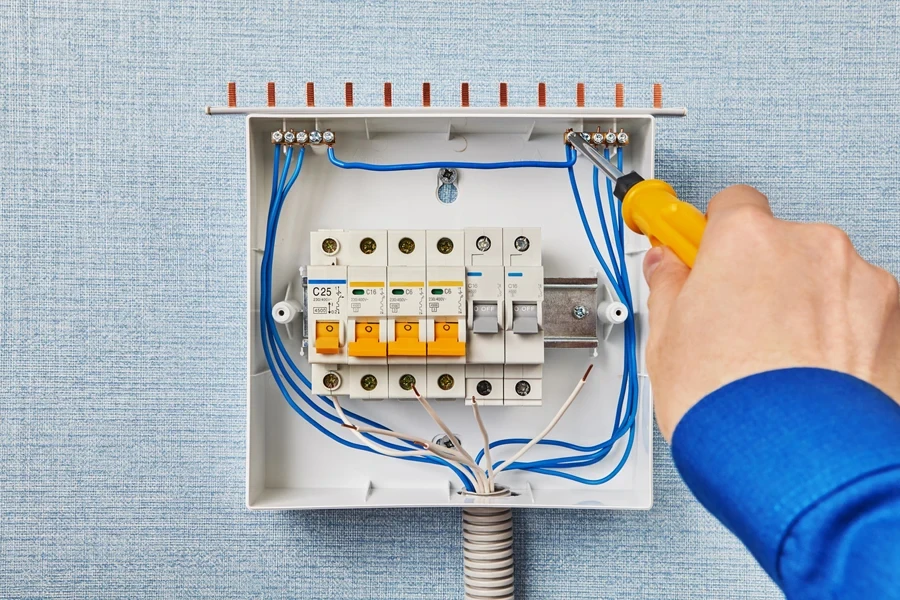

Industrial switching power supply: Suitable for industrial automation, communication equipment, etc., requiring high reliability and stability.

Commercial grade switching power supply: Suitable for commercial buildings, office equipment, etc., requiring better performance and ease of use.

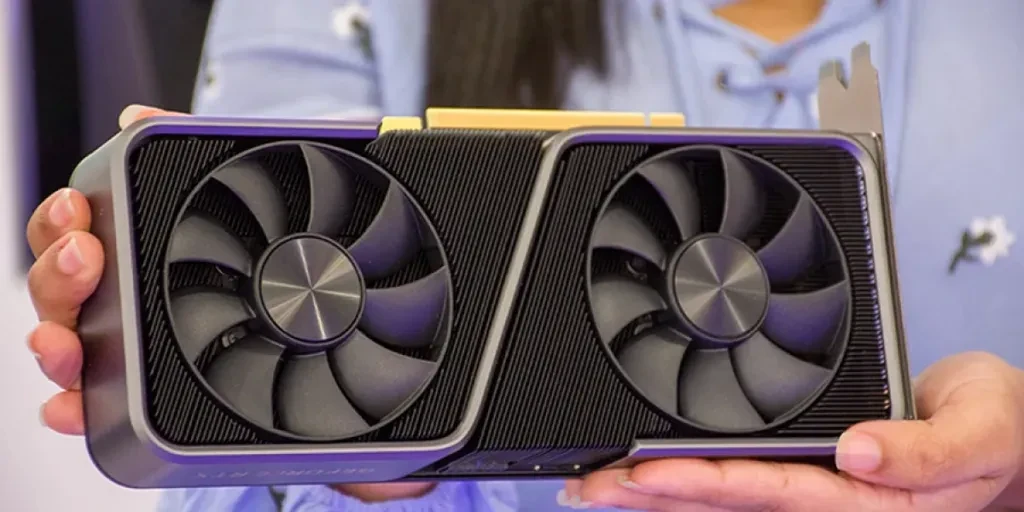

Consumer switching power supply: Suitable for household appliances, personal computers, etc., requiring small size and low cost.

Medical grade switching power supply: Suitable for medical equipment, requiring strict electromagnetic compatibility and safety standards.

Other classifications of power supply

Communication power supply: DC/DC converter type power supply used in communication systems.

Special power supply: High-voltage and low-current power supply, high-current power supply, 400Hz input AC/DC power supply, etc.

Latest developments

Switching frequencies have now reached the MHz level. Since surpassing the 20 kHz barrier in the 1970s, advances in technology have propelled switching frequencies to the range of 500 kHz to 1 MHz. Soft switching technology, which theoretically reduces switching losses to zero, has seen significant development and application.

Key circuit designs include quasi-resonant circuits, zero-switching PWM circuits, and zero-conversion PWM circuits. Notable technologies that have matured include active clamp ZVS and full-bridge phase-shift ZVS soft switching, both of which can achieve over 90% efficiency.

The emergence of switching technology hasn’t overshadowed hard switching. Instead, combining the two has breathed new life into the field. Zero Current Transition (ZCT) and Zero Voltage Transition (ZVT) technologies merge the low switching loss, high frequency, and energy-saving benefits of soft switching with the filtering and current handling advantages of hard switching.

Synchronous rectification technology also significantly boosts switching power supply efficiency.

By using low-resistance (less than 3 mΩ) MOSFETs instead of diodes for rectification, a controller synchronizes gate drive signals with rectified voltage, minimizing rectification losses. This method is particularly effective for low-voltage, high-current power converters.

Digital technology enhances product performance by facilitating human-machine interaction through interfaces like external keyboards and liquid crystal displays. It enables data communication with host computers via RS485, RS232, CAN bus, and other interfaces, allowing for telemetry and remote control. Digital power supplies also support online maintenance, self-tests, and upgrades through their network interfaces, significantly enhancing reliability and longevity.

Modularization in power supply circuits and systems boosts quality by allowing designers to use various functional modules flexibly. This enhances manufacturing efficiency, reduces costs and size, and improves reliability.

Manufacturers have integrated control functions such as PFC, ZVS, ZCS, PWM, parallel current sharing, and phase-shifting full bridge control into specialized chips. By packaging power switch devices, control, drive, protection, detection, and other circuits into a single module, people can integrate control, power semiconductor devices, and information transmission functions.

Conclusion

In short, switching power supply is an indispensable part of modern electronic equipment, with important roles and advantages. In the future development of science and technology, switching power supplies will continue to be developed and improved to meet the needs of electronic equipment in terms of high performance, high efficiency, high stability, and reliability.