Given the wide variety of cranes available, why would you choose a self-erecting mobile tower crane over other types of tower cranes and other types of mobile cranes? How do these cranes compare to other types available?

This article offers some selection guidance for these mobile cranes and looks at some of the top choices on the market.

Table of Contents

The growth of the mobile crane market

An introduction to self-erecting mobile cranes

A short comparison to other similar types of crane

A sample of self-erecting mobile cranes available

Final thoughts

The growth of the mobile crane market

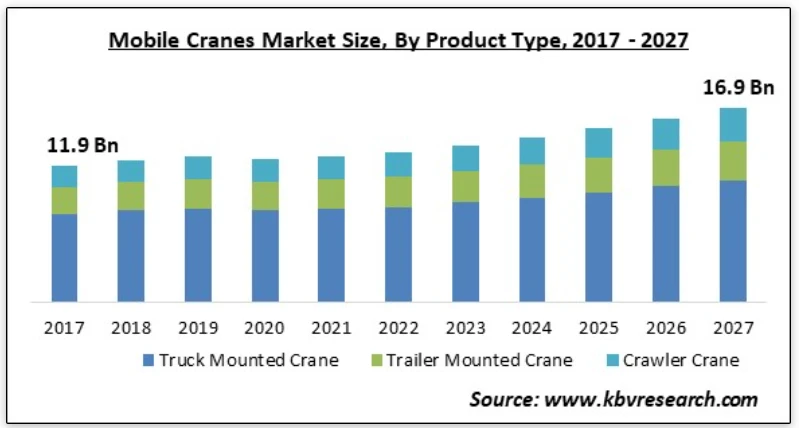

Mobile cranes make up a market segment of the overall crane market, with this segment including truck cranes, crawler cranes, and towed cranes. The category of towed cranes, or trailer-mounted cranes, includes self-erecting mobile cranes, spider cranes, and other small crane types.

Global market analysis of mobile cranes projects this segment to grow at a compound annual growth rate (CAGR) of 4.8% from 2017 to 2027, reaching a value of US $16.9 billion through the forecast period.

The global tower crane market also includes self-erecting mobile cranes, and the global tower crane market is projected to grow at a CAGR of 5.1% through the period from 2022 to 2028, growing from a value of US $7.0 billion in 2022 to US $9.6 billion by 2028.

Overall, self-erecting mobile cranes are showing healthy growth as they offer many of the benefits of tower cranes yet offer the flexibility and speed of mobile cranes.

An introduction to self-erecting mobile cranes

Self-erecting mobile cranes are, in essence, folding/unfolding versions of small tower cranes. Their mast sections collapse onto a trailer bed that can then be towed from one location to another. On site, they can then hydraulically open and extend up to their working height, with typically two sections of mast and two sections of main jib.

When fully extended, a self-erecting mobile crane looks much the same as a fixed base tower crane and structurally shares many characteristics with a tower crane. They have a firm base once set up and with outriggers extended. They have a tall single lattice-framed mast, an extending lattice main jib, and a lattice counter jib with an A-frame-like support. The block and hook slide in and out with a “racking” movement as they would on a tower crane.

One significant structural difference between fixed tower cranes and self-erecting ones is that, on a fixed tower crane, the slewing platform (rotating table) and control cabin sit on top of the mast, looking down over the worksite, whereas on a self-erecting mobile crane, the slewing platform is fixed at the base, looking across the worksite and up at the load.

Self-erecting mobile tower cranes may sometimes be confused with fixed tower cranes, also known as “climbing” tower cranes. These are actually not mobile and don’t unfold hydraulically from a transportable base. They are static-anchored tower cranes that are assembled or disassembled in place, but that can increase their own height by introducing new sections into their mast as they “climb.”

From a mobility viewpoint, self-erecting mobile cranes do not have their own engines, but are easily moved around by towing. Once on site, they are fast to erect and occupy a small footprint, yet they can have a wide turning jib radius from the slewing platform. They are very flexible, although this agility also comes with limitations on height and weight, so they are best suited for small construction sites.

Self-erecting mobile cranes have a fairly modest lifting capacity, usually in the 3–4 ton maximum range, although there are a few extra-large models available that can handle up to around 10 tons. Lifting height is also typically modest, between 60 and 130 feet.

A short comparison to other similar types of crane

Here is a brief comparison between self-erecting mobile cranes and other types of mobile crane, spider cranes, mobile truck cranes, crawler cranes, and bridge cranes:

Spider cranes

Spider cranes are comparable in lifting capacity, with the bigger ones having a weight capacity of up to around 12 tons that can be lifted up to as high as 50 feet. The boom is a telescopic box boom, with four extendable outriggers providing stability. Spider cranes are small and compact and have a small footprint, so they are a good option for small access sites. They move around on a small track under their own power.

Mobile truck cranes

Mobile truck cranes offer a different comparison to self-erecting mobile cranes. Truck cranes are stable once anchored with their outriggers and can be very fast to raise up or down and to move from one location to another. These cranes can usually lift up to around 400 tons, although the bigger cranes can lift upwards of 1,200 tons. Their compromise is with height, as they use an extending box boom that has heights of up to around 260 feet.

Crawler cranes

Once fully assembled, crawler cranes can lift up to 3,000 tons and reach heights of around 650 feet. They are mobile, moving on caterpillar tracks, but move slowly and are not roadworthy. They do require some assembly to reach higher heights, as the boom is not extendable.

Their lattice boom and jib needed to be fitted together, and their counterbalance is achieved by loading on heavy counterweights. Therefore, crawler cranes are designed for heavy lifting to great heights with a low center of gravity, but they still need assembly and are slow to move around from location to location.

Bridge cranes

Bridge cranes, also known as overhead cranes, are commonly fitted within a working industrial environment such as a warehouse. There are two parallel girder rails on either side and a single traveling girder that spans the gap between them.

They can lift very large weights—100 tons or more—up to the maximum height determined by the parallel beams, subject to the strength of the supporting infrastructure. They are not mobile cranes and are fixed in place, but the traveling beam moves up and down the length of the supporting beams.

The advantage of self-erecting mobile tower cranes

The big advantage that self-erecting mobile tower cranes have over other mobile cranes is their wide radius turn, which allows them to extend out from the main mast and rotate over the working site and nearby low buildings.

They function like fixed tower cranes, moving the jib around from the central mast, lifting the load by racking the block inward so as not to over-extend the weight and balance, and can then rotate and move the load to any desired location, low or high.

By comparison, other mobile cranes that use a single boom, extending at an angle from the base, have more difficulty avoiding low obstacles and placing loads in extended or higher locations. Self-erecting cranes also include advanced load and balance monitoring systems to warn against and avoid over-balancing by over-extending the load along the jib.

Comparing to fixed tower cranes

Self-erecting mobile tower cranes also compare favorably with fixed tower cranes and have become popular on smaller sites for their ease and speed of assembly and relocation.

Whereas fixed tower cranes can lift loads upward of 150 tons to heights of around 250 feet (higher if anchored within a building), they achieve their lifting power by being firmly anchored to a concrete base and/or within a building frame. However, set-up can take weeks, so these types of cranes cannot offer the same mobility and speed of assembly and disassembly as their self-erecting counterparts.

A sample of self-erecting mobile cranes available

This Hunan Tant 1.5 to 2 ton self-erecting mobile crane can lift to around 82–98 feet, selling for around US $20,000.

The XJCM self-erecting mobile crane comes in sizes from 1-4 tons and can lift up to 65-82 feet, selling for US$57,800, but with substantial reductions for multiple units.

This QTK25 3-ton-capacity self-erecting mobile crane can lift to 115 feet and is available for US$65–66,000, depending on the number of units.

This TCK10 crane has a 1-ton lifting capacity of 82 feet and sells for between US $25,800 and US $28,500.

This JFYT25-27 self-erecting mobile crane from ACNtruck Vehicle and Machinery can lift up to 3 tons to 80 feet. It sells at US$120,000, but that comes down to US$98,000 for 3 units or more.

This JFYT 1720–10 self-erecting mobile crane from Oriemac lifts around 1 ton to 65 feet. The image above displays it extending out, showing the positions of the racking block and hook when folded. This model sells for between US $19,500 and US $20,000, depending on the number of units.

This Taian Avencer self-erecting mobile crane can lift 3 tons to a height of 65 feet. This model is available for US $24–25,000. In the above image, the compactness of a folded crane can be seen as it unloads from a shipping container.

Although most of the self-erecting mobile cranes are of modest lifting capacity, in the 1–4 ton and 60–100 feet range, there are a few super-large capacity models on the market. This large version from ACEL A/S has heavy-duty outriggers and is stacked with counterweights. When extended, it can lift up to 9 tons, reaching a height of over 400 feet.

Although this large machine is self-erecting, as it unfolds for use and compacts for transport, it will require additional time to achieve a stable base and load the counterweights. It will also require heavy transportation for towing. Check the above link for pricing for this model.

Final thoughts

Whereas tower cranes are a familiar sight on the horizon of high-rise construction sites, a number of those cranes are not fixed but are actually mobile self-erecting types. Self-erecting cranes are an increasingly popular choice over fixed versions because of their convenience and mobility. Fixed tower cranes take weeks to assemble, requiring a concrete base and sections of the crane to be installed as the crane rises. In reverse, this takes time to lower and disassemble the crane.

Most self-erecting tower cranes can handle loads of 2–3 tons up to around 100 feet or more, which is sufficient for many small construction sites. There are even much larger versions that can compete well with fixed tower cranes for capacity yet still offer better mobility.

Compared to other mobile crane types, the tower crane structure of the main mast and slewing jib offers more flexibility around a construction site than other angled boom cranes.

For a potential buyer, the needs and limitations of a construction site will guide the selection of the best machine for the purpose. For more information on the wide selection of tower cranes available on the market, check out the online showroom at Alibaba.com.