Many lasers are on the market today, each with their own features, specifications, and integration levels, making the selection process difficult. When choosing a laser for material processing, it is critical to understand the differences and benefits of each option.

This article gives readers an understanding of laser systems, common types of lasers, and how to choose a suitable industrial laser source for material processing.

Table of Contents

The global industrial laser market

What is an industrial laser source?

Features to consider when choosing a laser source

The bottom line

The global industrial laser market

The industrial laser market was valued at USD 17.3 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 7.2% to reach USD 34.8 billion by 2030. A light beam is produced by an industrial laser system using stimulated emissions for various purposes in electronics, automotive, medical, and other industries. Lasers are primarily used for brazing, labeling, engraving, cutting, welding, and marking.

The growing demand for increased efficiency, productivity, and precision has resulted in the growth of industrial lasers. Furthermore, the rise in demand for material processing in various sectors and the transition of the automotive industry to electric vehicles will drive sales in the future.

What is an industrial laser source?

A laser has various components and features that produce an intense, coherent beam of light via an optical amplification process. There are numerous types of lasers, each with varying degrees of integration. All of these lasers, however, share a basic set of components.

The energy source for each laser directs light into a gain medium. This gain medium emits a specific wavelength of light, and a resonator amplifies this optical gain through mirrors.

Before getting into the specifics of a laser source, let’s take a look at some of the most common lasers:

Solid-State Lasers: As their primary source of optical gain, these lasers rely on solid glasses or crystals mixed with other earth elements. Typically, these mixed elements are erbium, thulium, chromium, or ytterbium. The most common solid-state laser in industrial processing applications are ruby and Nd:YAG.

Gas Lasers: By using a technique known as population inversion, electric current is passed through a gas in these lasers to produce light. Carbon dioxide (CO2), argon, krypton, and helium-neon are the most popular gas lasers. CO2 lasers are the most popular option and are widely used for laser welding, cutting, and marking.

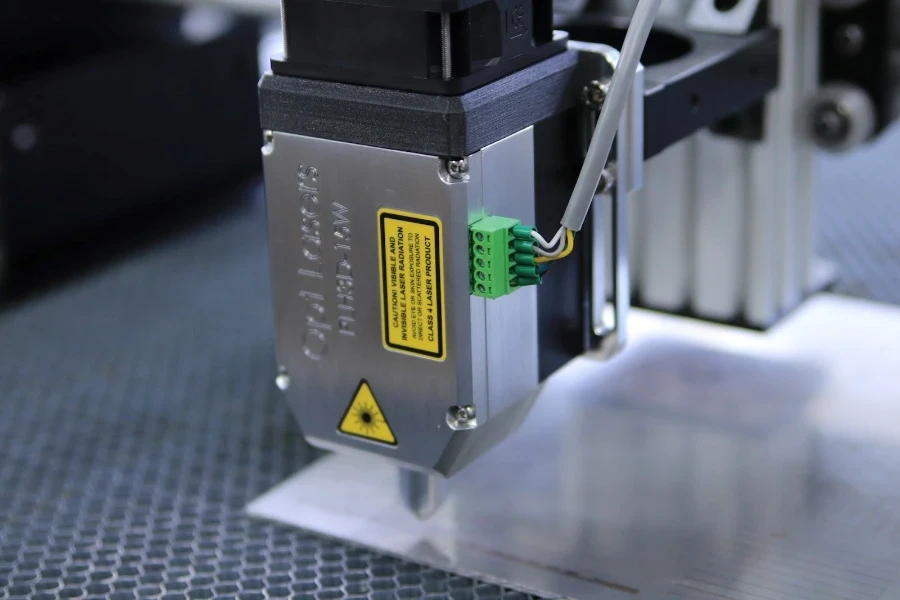

Fiber Lasers: Fiber lasers have narrower and smaller laser beams than other lasers, making them more precise in material processing applications. They have a small footprint, are energy efficient, and have low operating and maintenance costs. Fiber lasers are widely used in cleaning, welding, cutting, and marking applications.

Features to consider when choosing a laser source

The first step is identifying the laser type depending on the laser application. After deciding on the type of laser, one must specify its parameters, including the power, size, and wavelength of the beam and the maintenance cost.

Wavelength of the laser beam

It is critical to examine the wavelength of the laser beam for material processing because different materials have different absorption rates at different wavelengths. One widely accepted rule is that the 1064 nm wavelength laser beam of a Nd:YAG laser is well absorbed by steel and aluminum, whereas the 10600 nm wavelength laser beam of a carbon dioxide (CO2) laser is well absorbed by cloth, plastic, leather, wood, and paper.

The two most common laser sources available today are CO2 and fiber. depending on the elements mixed into the fiber. A CO2 laser can produce a laser beam at 10600, 10300, or 930 nm, depending on the gas composition. It is important to match the wavelength of the laser source to the material to be processed to ensure effective laser operations.

Maintenance costs

In the past, the glass tube CO2 lasers and lamp-pumped Nd:YAG lasers were popular, but their pump sources, that is, the arc lamp or gas-filled glass tube had to be replaced periodically. Every 500 to 1000 working hours, users had to stop the machine and replace the tube or lamp. Furthermore, older-generation CO2 lasers require a continuous flow of gasses through the resonator, resulting in high operating costs.

However, thanks to advanced technology, fiber lasers, the most popular choice today, accounting for 80% of the market share, are entirely maintenance-free. They have a long service life and a unique laser resonator design in which all optics are part of an efficient continuous fiber optic cable.

Power and focus size

The laser beam can be sent through a focusing optic while being pulsed at different lengths. When the beam comes into contact with the workpiece, it shrinks in size, effectively focusing a large amount of energy into a small area. However, the laser’s output cannot be reduced to a size smaller than its wavelength, nor can a low-quality output generate a high-quality focus point. For example, a CO2 laser cannot reduce the focus spot to less than 10600 nm, requiring a near-perfect beam and optics to complete the task.

Thus, while spot size is an important consideration, it is not required for all applications, such as laser surface cleaning, laser welding, and ladder sintering, which require a larger spot size to ensure performance.

Laser processing material

As different materials have different processing rates, the properties of the material must be considered when choosing the right laser source. The most suitable materials for CO2 laser marking, engraving, and cutting include plastics, foams, fabrics, rubbers, papers, glass, ceramic stone, steel, titanium, wood, and composites. Materials with extremely high melting points are ideally unsuitable for CO2 lasers under 200 W.

Fiber lasers are suitable for a variety of materials, including black acetal, acrylic, PTFE, and plastics containing fillers, pigments, or laser-receptive additives.

Mode of operation

CW (continuous wave) laser

It is critical to know whether the laser is continuous or pulsed. The average power of CW lasers is measured in kW or nW. Before selecting a sensor for CW lasers, the average power range must be determined. This range will determine the right choice of sensor. For instance, if the range is too wide, a second sensor will be required. Thus, choosing a sensor with a range close to the required range—not at the high or low end, but in the middle—may result in faulty readings if the range exceeds in either direction.

To select the appropriate sensor, the exposure time of CW laser laser beam must be considered. If only periodic measurements are required, a sensor with an exposure time long enough to obtain a stable reading, that is tens of seconds, is sufficient—preferably a smaller and less expensive sensor. However, if the laser must be exposed to the power sensor for extended periods, a larger sensor is required to dissipate any heat build-up that could affect the measurements.

Pulsed lasers

As with CW lasers, the energy range requirements for the sensors must be determined. Users must identify the laser’s pulses per second (PPS) or pulse rate to determine whether an energy sensor can be used for a specific application. Most energy sensors operate at frequencies ranging from 1hz to 5 kHz, with advanced sensors operating at up to 25 kHz.

Another factor to consider with pulsed lasers is the pulse width. This specification has a significant impact on the selected sensor’s damage threshold. For example, if the pulse width is too short, the energy density may exceed the sensor’s rating. If too long, the sensor’s circuitry may not have enough integration time, resulting in faulty operations.

The bottom line

Choosing the right laser source is essential to maximize productivity and enhance precision. This article provides some insights about laser sources and features. Visit Alibaba.com to check out the latest laser equipment for industrial applications.