Centrifugal fans are the most popular fan types in the current heating, ventilation, and air conditioning (HVAC) market. They are also considered one of the most versatile and efficient kinds of air moving equipment.

Developments in the industry have seen modifications in traditional centrifugal fans as well as new innovations. While this is positive, it does mean that choosing a suitable centrifugal fan can be challenging due to the numerous models available in the market.

This guide will give an overview of this market, before discussing some essential tips that will help you to select the right centrifugal fans to meet your needs.

Table of Contents

The business potential of centrifugal fans

Types of centrifugal fans

How to select centrifugal fans

Conclusion

The business potential of centrifugal fans

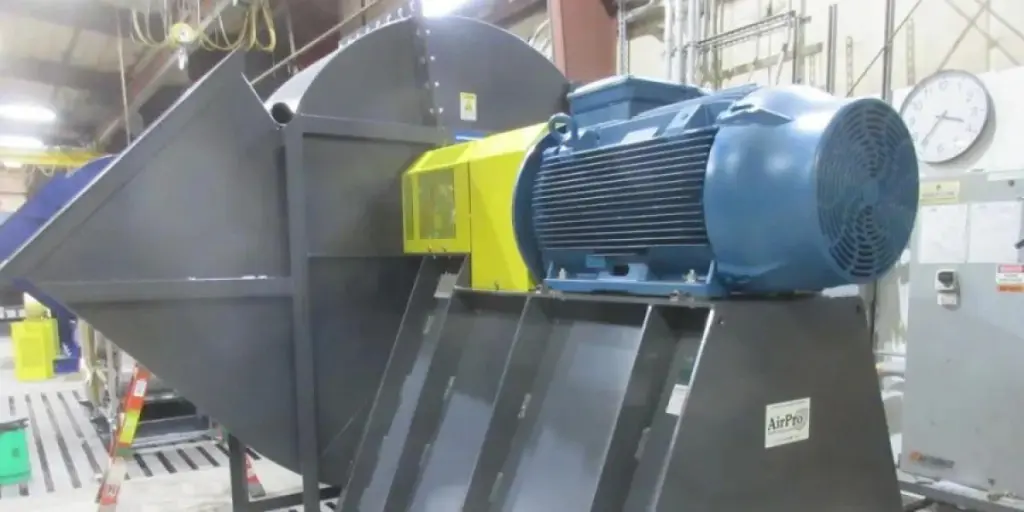

A centrifugal fan is a pump or motor that moves air. It pulls air inside a blower and pushes it out at a 90-degree angle. A centrifugal fan has two main components: a motor/pump and an impeller.

Fans are used in various industries, including mining, construction, petrochemical, cement production, electrical power production, and building heating and ventilation.

Rapid industrialization drives the global centrifugal fan market growth, which is also supported by increased investments in research and development for superior centrifugal fans. The market is expected to grow at a compound annual growth rate (CAGR) of 4%.

Types of centrifugal fans

Forward-curved centrifugal fan

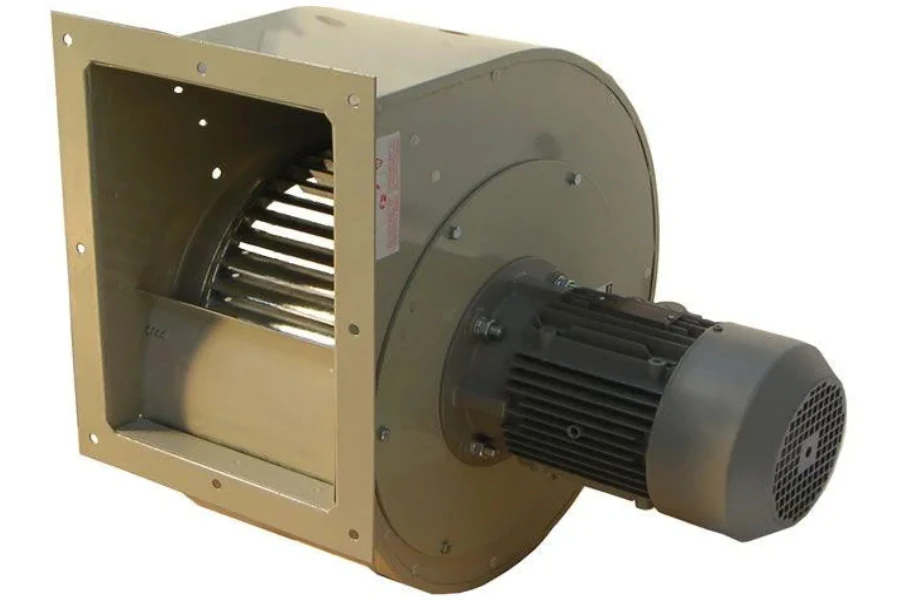

A forward-curved centrifugal fan is a centrifugal fan with blades that curve forward. These fans are typically used in HVAC systems and industrial process applications.

The design of forward-curved fans allows for high efficiency, low noise, and compact size. They work by converting the energy from the motor into kinetic energy, which is then converted into pressure energy by the fan blades. This results in a high-volume airflow at a relatively low static pressure.

Forward-curved centrifugal fans are commonly used in a wide range of applications, including:

- HVAC systems, such as air handling units, rooftop units, and make-up air units

- Industrial process systems, such as dust collection and fume exhaust systems

- Power plants, such as boilers and furnaces

- Ventilation systems, such as exhaust and supply systems.

Due to their efficiency and compact size, forward-curved centrifugal fans are also well-suited for retrofit projects with limited space.

Backward-curved centrifugal fan

A backward-curved centrifugal fan is a type of centrifugal fan with blades that curve backward. These fans are typically used in high-pressure, high-volume applications such as power plants and industrial process systems.

The design of backward-curved fans allows for high efficiency, low noise, and compact size. They work by converting the energy from the motor into kinetic energy, which is then converted into pressure energy by the fan blades. This results in a high-volume airflow at a relatively high static pressure.

Backward-curved centrifugal fans are used in various applications, including power plants, HVAC systems, ventilation systems, and industrial processes.

Backwards-curved fans have a steeper slope in the fan curve, which results in a higher pressure rise per unit volume and a lower volume flow rate than forward-curved fans.

They are also less sensitive to system resistance changes, making them suitable for systems with variable resistance.

Airfoil centrifugal fan

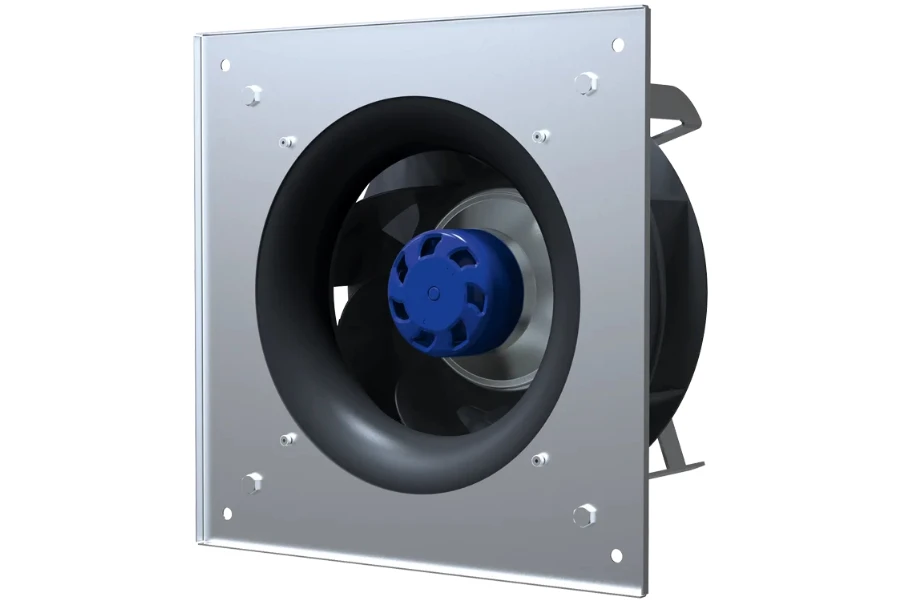

An airfoil centrifugal fan is a centrifugal fan with blades shaped like airfoils. These fans are used in high-pressure, high-volume applications such as air conditioning and industrial systems.

The airfoil shape of the blades allows for high efficiency and low noise, as it reduces the turbulence and drag that occurs in other types of centrifugal fans.

They work by converting the energy from the motor into kinetic energy, which is then converted into pressure energy by the fan blades. It results in a high-volume airflow at a relatively high static pressure.

Airfoil centrifugal fans are used in various applications, including ventilation systems, power plants, industrial processes, and HVAC systems.

Due to their high efficiency and low noise, airfoil centrifugal fans are well-suited for applications where energy efficiency and low noise levels are critical.

They also have a flatter fan curve than other types of centrifugal fans, which makes them more resistant to changes in system resistance.

How to select centrifugal fans

Volume flow rate

The volume flow rate is the amount of air the fan can move and is measured in cubic feet per minute (CFM) or cubic meters per second (CMS).

The required volume flow rate will depend on the application and the space size. It is essential to consider your space and application volume flow rate needs when selecting centrifugal fans.

Static pressure

Static pressure is the resistance to airflow caused by ductwork, filters, and other components in the system.

The fan must overcome static pressure to move the required air volume. The static pressure required will depend on the application and the ductwork in the system. Determine the static pressure of your systems before purchasing a centrifugal fan.

Power consumption

The fan’s power consumption is typically measured in horsepower (HP) or watts (W) and will depend on the required volume flow rate and static pressure.

Selecting a fan that is energy efficient and uses the minimum amount of power to operate is essential in cutting down operational costs.

Noise level

The fan’s noise level is measured in decibels (dB) and will depend on the application. It is essential to select a quiet fan that will not disturb the space where it is installed.

Consider the noise level and the effect on the human personnel. High fan noise can affect employees’ concentration hence affecting productivity.

Dimension and space availability

The size of the fan and the space available for installation should also be considered when selecting a centrifugal fan.

If you have ample space available, going for a high-power centrifugal fan is a good option due to its overall effectiveness. However, small centrifugal fans are suitable for small businesses due to space limitations.

Environmental considerations

Some fans may be suitable for specific environmental conditions such as hazardous locations, corrosive environments, and high temperatures.

Others are vulnerable to environmental hazards and hence only suitable in protected spaces. Consider the environmental conditions of the installation location before selecting a centrifugal fan.

Conclusion

Centrifugal fans have positively impacted various industries. The growth of industrialization is expected to increase the demand for centrifugal fans.

The guide will help you select a suitable centrifugal fan to meet your business needs. To learn more, and to browse listings of quality centrifugal fans, visit Alibaba.com.