Today, artificial intelligence (AI) appears to power everything in our lives, from the way we shop with chatbots that seem to read our minds, to our commutes, where autonomous cars drive themselves.

It’s no wonder that businesses of all types around the world are rapidly integrating AI into their operation systems. A recent survey by McKinsey & Company unveiled an impressive AI adoption rate, which is 2.5 times higher today than it was in 2017.

AI’s ability to automate repetitive tasks and quickly analyze large volumes of data allows businesses to streamline their processes, making them more productive and efficient. For these reasons, the use of AI in supply chain operations is no longer an optional extra—it’s the engine that drives performance and fuel efficiency.

With AI algorithms, companies can predict delays, identify potential disruptions in their supply chains, and even optimize warehouse operations, from sorting and packing goods to managing inventory levels.

Sound interesting? Continue reading as we explain what AI is all about and how it can revolutionize supply chains in six innovative ways!

Table of Contents

The ABCs of AI: A breakdown of its basics and current state

How is AI used in supply chains?

Towards an AI-optimized supply chain: final thoughts

The ABCs of AI: A breakdown of its basics and current state

Artificial intelligence (AI) is a branch of computer science that aims to create machines and software that can mimic human intelligence. Does that sound overly complex or technical? It doesn’t have to be—let’s explore what AI really is together before delving into its uses within supply chain management.

What is artificial intelligence (AI)?

Artificial Intelligence, or AI for short, is like giving a computer a brain that can think, learn, and solve problems somewhat like how humans do. It’s not a brain made of cells and neurons, but one made of programming code that uses data and experiences to get better at tasks.

These tasks could be anything from understanding spoken words (like Siri or Alexa do), recognizing pictures (like Facebook identifying your friends in photos), recommending what video to watch next (like Netflix does), or even driving cars. AI can be split into two big types based on what it does with the information it gets:

- Discriminative AI: This subset of AI is all about identification. For example, if you show it a bunch of photos, it can figure out which ones have cats in them and which don’t. It’s like a detective that looks at clues (data) to figure out “whodunit” (identify things).

- Generative AI: Instead of just identifying stuff, generative AI can actually make new things. It doesn’t just know what a cat looks like; it can imagine a cat that doesn’t even exist and then generate a photo or a tale about it from scratch.

What are the current AI technologies?

Current generative AI tools have become increasingly capable of accomplishing various tasks and roles, from clerical tasks and content creation to design and manufacturing. We can categorize the current AI technologies into two categories: those related to text and sound, and those related to image and video.

Text and voice generation

Generative AI is transforming the way we create text and sound, making it easier to produce everything from written content to music. Conversational tools like ChatGPT and Gemini are trained on vast content from the internet. They can hold conversations, draft emails, write essays, answer questions, and even create written content from scratch.

When it comes to voice and sound, the advancements are equally impressive. For instance, tools like OpenAI’s MuseNet and Jukebox can generate musical compositions in a variety of genres, or they can be given lyrics and a musical style and generate an original piece from that input.

Image and video generation

The natural language processing of AI is also changing the game in the world of images and videos. Imagine typing a simple description of a scene and getting a detailed, original image that matches your words. That’s exactly what tools like DALL-E do. You can tell DALL-E, “Draw me a pink elephant flying in the sky,” and voila, you’ll get an image just like that.

When it comes to video, the advancements are even more exciting. OpenAI has recently introduced Sora, a text-to-video AI tool that can create videos that are rich, detailed, and realistic. So, someone can tell Sora to make a video about a dragon and a knight having a dance-off, and Sora can generate that video, making it look like a real little movie scene.

How is AI used in supply chains?

Now that we know what artificial intelligence is all about, including its latest breakthroughs, you might be wondering what exactly the role of AI in supply chain management is. Keep reading as we explore six practical applications of AI in global supply chains.

1. Demand forecasting

If there is anything powerful about AI, it certainly can process and analyze big data—vast quantities of information that our human minds cannot assimilate—in real time. Firstly, AI examines these large datasets that could include the volume of past purchases, prevailing weather conditions, current social media trends, and any major upcoming events that could shift consumer purchasing preferences.

Then, by leveraging a technique called machine learning, AI learns from all this data to predict the quantity needed for a specific product and when customers will likely want to purchase it. By predicting customer demand more accurately, companies can better align their inventory levels with expected demand, reducing holding costs and minimizing the risk of unsold stock.

Amazon is a prime example of a company using AI algorithms to revolutionize demand forecasting. By using Amazon Forecast, a service based on machine learning, Amazon can predict future demand for millions of products globally in mere seconds.

Amazon’s virtual shelves are stocked with just enough items because the AI predicts how many will be sold. And since they have a better idea of what will be needed and where, Amazon can move items closer to where customers live before they even click ‘buy.’

2. Warehouse optimization

Warehousing is a vital part of supply chain management, serving as the backbone that enables businesses to keep their products safely stored, organized, and readily available for shipping to customers. However, warehousing is riddled with logistical challenges, such as predicting the right amount of stock to keep, figuring out the best way to organize items for fast access, and even handling the physical task of moving goods around the warehouse.

AI algorithms can analyze historical data on product movement and demand patterns to design or suggest optimal warehouse layouts. This includes identifying the best locations for goods based on their size, weight, and frequency of access, thus ensuring a logical placement that maximizes space utilization and minimizes picking times.

For instance, Ocado, a pioneer in grocery tech, leverages AI to automate its warehouse operations. While traditional warehouse designs dedicate significant floor space to aisles for human workers to pick items, Ocado’s warehouses are highly automated, wherein every square meter is purposed towards product storage, and autonomous mobile robots (AMRs) retrieve and transport items as required.

These robots move on a three-dimensional storage grid, nicknamed a ‘hive,’ making optimal use of all potential storage space. The grid’s design allows robots to access any stored product from above, which is a stark shift from traditional warehousing. This design helps Ocado to store more goods in a limited area and quickly fulfill orders since robots can rapidly travel to any location in the grid.

3. Logistics and route planning

Time is of the essence in logistics. The ability of AI to analyze historical traffic patterns, current road conditions, weather forecasts, and more, enables it to predict and determine the most efficient routes for transportation. Less time on the road and more direct routes mean vehicles use less fuel, which not only reduces costs but also lessens the environmental impact of transport operations.

One of the key advantages of AI in transportation routing is its ability to adjust to changes as they happen. Should there be a delay due to traffic jams or road closures, the AI is capable of rerouting shipments in real-time, making necessary adjustments to schedules and routes. This is particularly useful when coordinating between different transportation modes such as trucks, ships, and trains as used in intermodal shipping or transloading.

For example, United Parcel Service (UPS), one of the largest package delivery companies globally, uses the On-Road Integrated Optimization and Navigation (ORION), an AI-based system, to dynamically optimize delivery routes. ORION recalculates individual package delivery routes throughout the day as traffic conditions, pickup commitments, and delivery orders change.

By dynamically optimizing routes, ORION significantly saves time and reduces fuel usage. The system reportedly manages to save 2-4 miles per driver each day, allowing more deliveries to be completed in a shorter timeframe.

4. Supplier evaluation and selection

In supply chain management, a good supplier translates to quality products, reduced costs, on-time deliveries, and, ultimately, satisfied customers. However, carrying out supplier evaluations involves screening hundreds of potential vendors to identify those who meet predetermined criteria (e.g., cost, quality, delivery times). This constitutes a substantial and error-prone manual workload.

Thankfully, AI algorithms can extract and analyze data from various sources, including supplier websites, performance records, industry reports, and online trade forums, enabling a more informed selection process. After processing all the data, AI can then automatically create and update detailed dynamic profiles for each supplier, incorporating factors such as:

- Quality performance: Historical quality metrics, return rates, compliance with quality standards (ISO certifications), etc.

- Financial stability: Credit scores, profitability trends, financial ratios analysis, etc.

- Delivery performance: On-time delivery rates, lead times, reliability in meeting delivery schedules, etc.

- Cost-effectiveness: Pricing competitiveness, cost structure analysis, total cost of ownership, etc.

- Technological capability: Adoption of advanced manufacturing technologies, intellectual property holdings, etc.

- Risk management: Exposure to geopolitical risks, supply chain resilience, history of handling disruptions, etc.

- Geographical considerations: Proximity to key markets or manufacturing sites, impact of logistics and transportation costs, etc.

After selection, AI can continue to monitor supplier performances. For instance, it might use sentiment analysis to gauge supplier financial health or detect early signs of instabilities or disruptions.

For example, IBM’s Emptoris Supplier Lifecycle Management application features a Performance Evaluation module designed to create, manage, and evaluate cross-functional supplier ratings.

This Performance Evaluation process assesses a supplier’s performance over a designated period, considering both quantitative (hard facts) and qualitative (e.g., innovation) measures. Alongside performance evaluation, IBM’s Supplier Risk module aids in early risk identification by conducting real-time risk calculations and triggering alerts accordingly.

5. Packaging optimization

Packaging is a powerful tool for branding and marketing; however, more importantly, it directly impacts the efficiency and cost-effectiveness of product distribution. Optimized packaging not only reduces material costs but also lowers shipping costs due to optimized weight and space utilization.

By analyzing factors such as product shape, fragility, weight, and the properties of different materials, AI can identify designs that use a minimal amount of material while still ensuring product safety during transit. Moreover, AI-powered tools can simulate and optimize packaging sizes and shapes to fit more products into each shipment, thus reducing the number of trips required.

A great real-world example is how Packsize, a leader in on-demand packaging solutions, relies on an AI-powered system to analyze the dimensions of each item to be packed and create custom-sized packaging for each order. The AI considers several factors, including:

- The dimensions of the item(s)

- Required protective space or padding

- The best orientation of the item within the box

- Material constraints and efficiencies

The result is an optimal packaging size that ensures the highest level of protection, minimizes the packaging material used, and reduces the space each package would take during transportation.

Moreover, Packsize’s on-demand packaging machines, such as the Box On Demand system, use the AI-recommended design specifications to automatically cut, fold, and glue the corrugated cardboard into a custom-sized box. The machinery translates the AI’s design into a physical package perfectly sized for the product.

6. Intelligent global sourcing

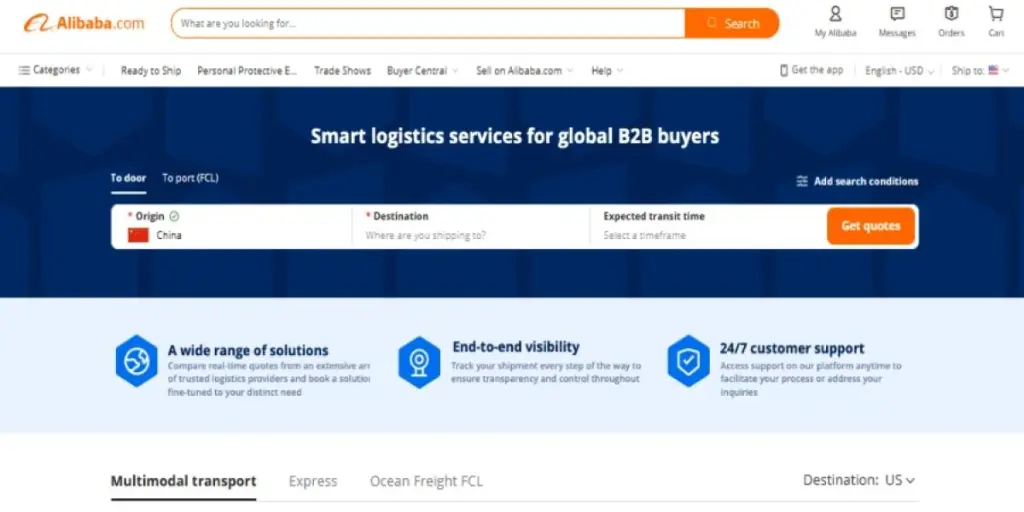

Global sourcing on B2B online platforms like Alibaba.com is increasingly becoming a strategic element of supply chain management. However, global sourcing presents an array of potential mistakes and challenges, especially for beginner business buyers.

For instance, buyers may face difficulties in finding the right product among millions of ones available. Moreover, engaging with suppliers from different countries introduces potential misunderstandings due to language barriers.

With AI, buyers can experience an optimized procurement process. AI algorithms can identify and track market trends, suggest the best times to source specific product categories, and even automate routine tasks in procurement, such as the creation of purchase orders, the processing of invoices, and the tracking of payments.

A great real-world example is how Alibaba.com leveraged AI through the Smart Assistant tool to provide 24/7 customer service for buyers and help them make the sourcing process as efficient as possible.

Smart Assistant is an AI-powered, intuitive personal guide to sourcing that helps businesses discover new opportunities, stay up-to-date on trends, seamlessly track orders, and more, all through a single, efficient touchpoint. Among many assistive functions, three key features to make global sourcing intelligent include:

- Upgraded Image Search

- Smart Request for Proposal (RFQ)

- Instant Help

The first two features were introduced in September 2023 and have since aided businesses in efficiently and accurately sourcing products. The Upgraded Image Search feature allows users to search for products using images, rather than text-based queries. Buyers can upload an image of the item they wish to purchase, at which point the Smart Assistant’s AI accurately interprets the image content to find visually similar products.

Conversely, the Smart RFQ harnesses AI to automate the process, making it quicker for buyers to generate RFQs. According to Alibaba.com, buyers who used the Smart RFQ tool witnessed a 29% increase in quotes from suppliers, while suppliers experienced a 21% rise in buyer responses to quotes compared to the traditional manual RFQ process.

The third feature, Instant Help, is planned for launch in 2024. This feature employs an AI chatbot that not only responds to basic inquiries but also offers real-time industry insights, essential industry knowledge, and product details. Additionally, it provides practical tips intended to enhance communication between buyers and suppliers.

Towards an AI-optimized supply chain: final thoughts

If there is anything we can take away from all the applications and examples, it is that AI can streamline the entire supply chain operations, from determining the demand for products to logistics and distribution. However, businesses should keep in mind some AI-related challenges that might hinder its application in supply chains, such as:

- Cybersecurity risks: For example, hackers can use AI to predict and exploit shipping routes or schedules.

- Ethical and privacy concerns: For example, AI surveillance technologies that monitor worker productivity without consent.

- High costs of implementation: For example, required upgrades to existing infrastructure to support AI integration.

- Integration with existing systems: For example, AI analytics tools that are incompatible with older ERP software.

Interested in learning more about how AI can revolutionize supply chain management? Check out this blog post to see how generative AI is managing all aspects of the customs brokerage process, from completing the necessary paperwork to estimating customs duties and taxes!

Looking for a logistics solution with competitive pricing, full visibility, and readily accessible customer support? Check out the Alibaba.com Logistics Marketplace today.