Transloading involves the transfer of goods from one mode of transport to another during their shipping journey. Unlike direct shipping, transloading allows for the efficient use of different modes of transportation depending on cost, timing, and destination requirements.

Furthermore, logistical bottlenecks such as congested ports or transport hubs can prompt delays and escalating costs in direct shipping. Transloading, however, enables shippers to bypass these congested areas by employing alternative routes or modes of transportation.

Now, you may be wondering, how exactly does transloading work? How does it differentiate from intermodal shipping? And how can businesses streamline their transloading processes to enhance efficiency and cost-effectiveness even further? Let’s unbuckle these questions and find out the answers!

Table of Contents

What is transloading in logistics?

Transloading vs. intermodal shipping: what’s the difference?

What are the operations involved in transloading?

3 strategies to streamline the transloading operations

Open communication: the secret to efficient transloading

What is transloading in logistics?

When goods need to be transported from their point of origin to their final destination, they cannot often make the entire journey with just one type of transportation. For example, they can’t go from a factory in China to a store in New York using only an airplane.

Instead, they have to use different transport modes, including ships, airplanes, trucks, and trains. This act of transferring goods from one type of transportation to another, such as from a ship to a truck, is called transloading.

This process occurs at what are known as transloading facilities, such as ports or warehouses, where goods can be unloaded and then loaded onto the next form of transportation. Transloading helps in improving shipment speed and cutting down costs by using the fastest and most cost-effective mode of transport available for each leg of the journey.

For example, shipping large quantities by train is often cheaper than trucking over long distances. However, trucks might be better for the final delivery after covering the major distance via rail, as they can quickly navigate local roads and deliver directly to specific addresses.

Transloading vs. intermodal shipping: what’s the difference?

Both transloading and intermodal shipping involve the use of multiple forms of transportation to move goods from the origin to the final destination. The primary difference between the two lies in the handling and containerization of the freight:

- Transloading requires the physical transfer of goods from one container or vehicle to another, often involving a transloading facility where goods are temporarily stored before being loaded onto the next transport vehicle.

- Intermodal shipping maintains the cargo in the same container throughout the entire journey, eliminating the need for direct handling of the goods when changing transport modes.

What are the operations involved in transloading?

The idea of moving goods from one form of transportation to another might sound simple, but the transloading process involves various steps. So, before exploring strategies on how to streamline transloading and make it efficient, let’s first understand how the process works from the arrival of goods at their origin to their transportation to the final destination.

Let’s imagine a garment brand based in Vietnam that wants to ship a cargo full of manufactured clothes to its client in Los Angeles, USA.

Step 1: Arrival of goods

First, the manufactured clothes are packaged and then transported from the production facility to a transloading depot by road using trucks. The use of trucks is most efficient given the country’s dense road networks.

Step 2: Unloading

At the transloading facility, the next step is the unloading of goods from the trucks. Skilled workers manually or mechanically unload the packaged clothes, ensuring each item is handled properly to avoid any potential damage.

Step 3: Inspection & documentation

After unloading, the cargo undergoes a thorough inspection to verify quantities, check for damages, and ensure the products match the documentation. The shipping documentation, which includes cargo manifests, packing lists, and export certification, is vital for confirming the goods’ integrity and ensuring smooth customs clearance in the destination country.

Step 4: Preparation for the new mode of transport

In this step, the goods are prepared for the next mode of transport. In this example, the most practical mode would be ocean freight, given the immense geographical distance between Vietnam and Los Angeles. The clothes are repackaged if necessary to fit into new containers that align with the shipping vessel’s requirements.

Step 5: Reloading

Once the goods are suitably arranged in the cargo containers, they are loaded onto the sea freight vessels. Here, crates of clothes are lifted and securely placed into the cargo ship. This process involves the use of cranes or other machinery, ensuring secure placement and efficient use of space in the cargo ship.

Step 6: Transportation to the final destination

Finally, the cargo ship carrying the clothes embarks on its voyage across the Pacific Ocean towards the port of Los Angeles. Upon arrival at the destination port, the containers are unloaded, go through customs inspections, the goods are then loaded onto trucks, and finally get delivered to the client’s warehouse.

3 strategies to streamline the transloading operations

From the previous example, we can see that transloading involves a series of complex operations and poses certain challenges. For instance, every time cargo needs to be transferred, it has to be unloaded from the current vehicle, moved to a waiting facility, and then reloaded onto the next vehicle. This process inevitably creates downtime.

Moreover, transloading requires additional resources in terms of handling equipment and manpower, as well as storage facilities to temporarily house the cargo while awaiting transport, which increases the total cost of logistics. But no worries! This section explores 3 practical strategies aimed at streamlining transloading operations to maximize their efficiency and cost-effectiveness.

1. Invest in logistics software

You guessed it; there is no better way to optimize logistics operations than through technology. Businesses, for example, can employ tracking software to monitor cargo as it transfers from ships to railcars.

The software can provide real-time updates on the location and status of each shipment, allowing managers to coordinate timely transfers and reduce waiting times. If there’s a delay with an incoming ship, the system will automatically notify the rail operations to reschedule the railcar positioning, avoiding unnecessary demurrage charges.

Moreover, logistics software with advanced algorithms can determine the most efficient routes for goods to travel. For goods being transloaded from trucks to trains, the software could assess various factors such as rail schedules, traffic patterns, and delivery times to determine the optimal transfer point, thereby reducing the time goods spend in transit.

For instance, Oracle Transportation Management (OTM) is a comprehensive software solution that supports planning across all modes of transportation, including full truckload, less-than-truckload (LTL), rail, ocean, air, and parcel.

The system calculates the most efficient routes based on various criteria such as distance, time, cost, and service level requirements. It can assess historical traffic patterns, weather data, and real-time traffic information to suggest the quickest or most fuel-efficient paths.

2. Adopt cross-docking

If we were asked which operation is the most inefficient and costly in transloading, the answer would certainly be the step of preparing a new mode of transportation, in which goods are unloaded, handled, and stored in a transloading facility.

To eliminate the need for this temporary storage of goods, businesses might adopt cross-docking, a logistics strategy that involves unloading materials from inbound delivery vehicles and loading them directly onto outbound vehicles, with minimal or no storage time. In simple terms, we make the transloading process more similar to intermodal shipping.

Cross-docking is especially effective for pre-tagged retail merchandise, fast-moving consumer goods (FMCG), and perishable items like food and pharmaceuticals. Let’s take the example of a fast fashion retailer. To make cross-docking possible, this retailer might use containers that are easily accessible and designed for quick unloading and sorting.

These specialized containers might allow for easy opening, or be modular for quick stacking and moving. When the pre-tagged shipment arrives at the cross-docking terminal, items are directly transferred from the incoming container to outgoing transportation modes (trucks, trains, etc.) without the need for storage.

3. Partner with third-party logistics providers (3PLs)

Peter Drucker once wisely stated, “Do what you do best and outsource the rest.” This is precisely why the preferred strategy for streamlining transloading operations is to collaborate with a third-party logistics provider (3PL). Partnering with a 3PL allows businesses to leverage their vast logistical expertise. The benefits that 3PLs provide include:

- Knowledge of best practices: 3PLs are up to date with the latest trends and practices in logistics, ensuring that transloading operations are as efficient as possible.

- Skilled personnel: They have trained staff who are experienced in handling diverse types of cargo and can manage the transloading process smoothly.

- Advanced technology: They use software for inventory management, tracking, and scheduling.

- Optimized networks: They often have established relationships with various carriers, which allows for smoother transitions between different transportation modes.

- Economies of scale: Due to the volume of business 3PLs handle, they can negotiate better rates with carriers.

Consider a company that manufactures furniture and needs to ship its products from its factory in China to its distribution centers across the United States. Instead of negotiating contracts with ocean carriers, managing the transition to rail or truck companies at U.S. ports, and then coordinating with local delivery services to get their products to the respective distribution centers, they could delegate the entire transloading process to a 3PL.

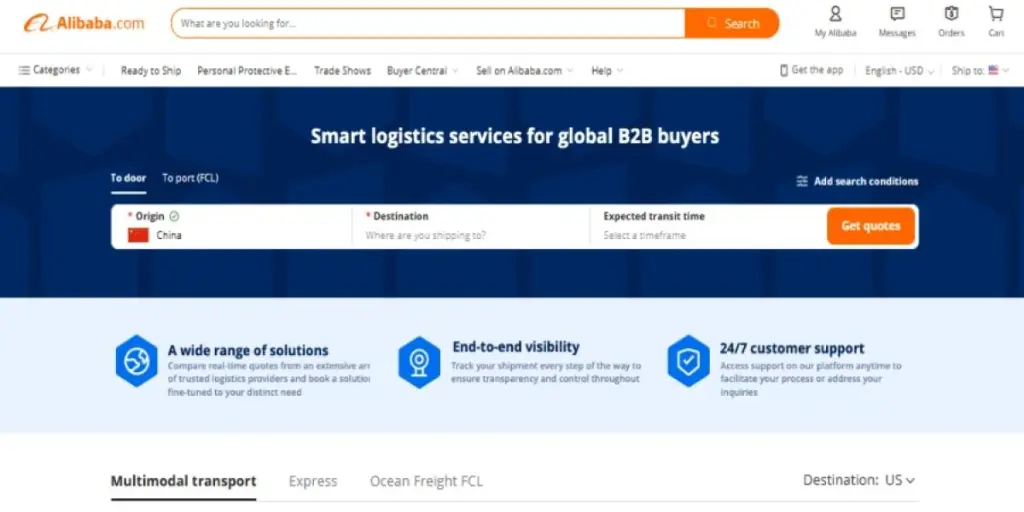

Wondering where to find such logistics providers? Simply visit Alibaba.com Logistics Marketplace to find reliable 3PLs offering comprehensive logistics solutions, from port-to-port to door-to-door services.

Open communication: the secret to efficient transloading

As we have seen, transloading is an efficient shipping strategy that leverages the strengths of various transportation modes to match the type of goods, the distance of the journey, geographic constraints, and logistical requirements.

Regardless of the strategy implemented by businesses, the key to efficient transloading significantly depends on open and real-time communication among all parties involved: shippers, carriers, and transloading facilities.

Find more insights and strategies about logistics by exploring Alibaba.com Reads!

Looking for a logistics solution with competitive pricing, full visibility, and readily accessible customer support? Check out the Alibaba.com Logistics Marketplace today.