In the fast-paced world of painting and color mixing, paint mixing machines have become essential tools for professionals and hobbyists. These machines have gained immense popularity worldwide because of their efficiency, accuracy, and time-saving capabilities. However, choosing a suitable paint mixing machine can be tricky with all the options currently available on the market today.

In this guide, we will explore the key features to look for when buying a paint mixing machine. Also, this guide will highlight the market share of these machines as well as the different types available.

Table of Contents

Paint mixing market

Types of paint mixing machines

How to buy the right paint mixing machines

Conclusion

Paint mixing market

The market share of paint mixing machines has experienced a significant increase in recent years, mainly due to several key factors driving their growing demand globally. A report by Future Market Insights shows that as of 2023, the global paint mixing market was valued at US$ 17.7127 billion, growing at a compound annual growth rate (CAGR) of 4.9%, with this figure expected to reach US$ 28.5785 billion by 2033.

One major factor leading to the increase in demand is the rising desire for customized paints and coatings, leading to a greater need for accurate color matching and consistency that these machines can deliver. Moreover, the expanding number of painting contractors, automotive refinishers, and industrial manufacturers has increased demand as they seek more efficient and time-saving solutions.

Regions such as North America, Europe, and Asia-Pacific have shown exceptionally high demand for these paint mixing machines, owing to flourishing construction and automotive sectors and a growing emphasis on eco-friendly solutions.

Types of paint mixing machines

1. High-speed dispersers

High-speed dispersers are potent tools to quickly and efficiently mix pigments and other components into paint or coatings. These machines employ a fast-rotating blade or impeller to break down particles and create a smooth and consistent mixture. They are perfect for achieving rapid dispersion and ensuring even distribution of colors, making them a popular choice for various applications.

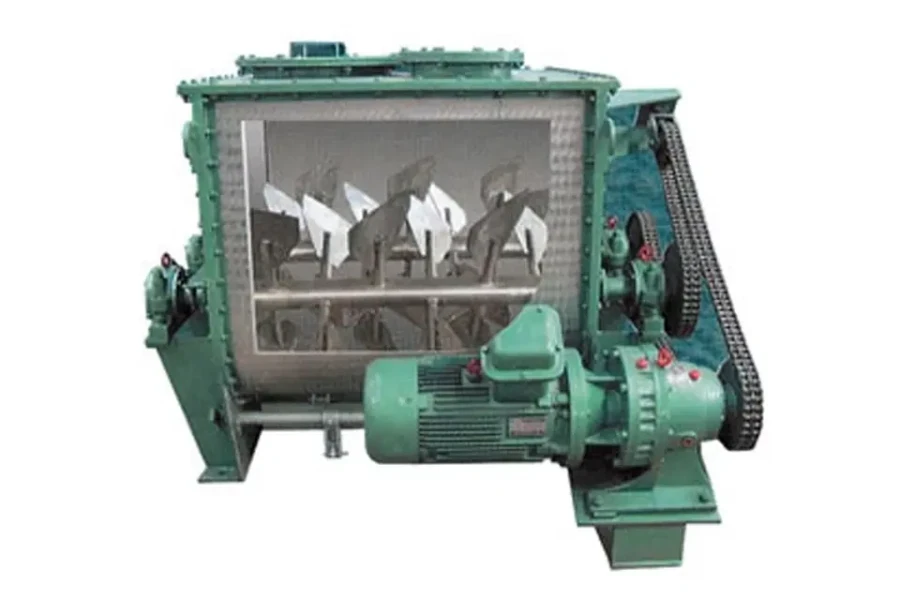

2. Dual-shaft mixers

Also known as double-shaft mixers, these machines have two mixing shafts that rotate in opposite directions. The ingenious design allows for thoroughly blending materials, which is especially helpful when dealing with thick or hard-to-mix formulations. Dual-shaft mixers are highly effective in producing homogeneous mixtures, making them suitable for various uses, including adhesives, sealants, and pastes.

3. Planetary mixers

Planetary mixers have a unique mixing action where the mixing blades rotate around their axes and travel around the mixing bowl’s center. This motion ensures efficient blending of materials with varying viscosities, guaranteeing a consistent and well-mixed final product. They are commonly used in producing high-quality paints, inks, and coatings.

4. Horizontal bead mills

Horizontal bead mills use tiny beads as grinding media to disperse and grind pigments and other solid particles in a liquid medium. These machines achieve fine and uniform particle size distributions, making them vital for creating high-performance paints, dyes, and colorants with excellent quality and consistency.

5. Three-roll mills

Three-roll mills find extensive use in the paint and ink industries for dispersing and blending materials by passing them through three horizontally positioned rollers. Their ability to offer precise particle size reduction and homogenization makes them indispensable for producing smooth, consistent formulations of paint, ink, and various coatings.

How to buy the right paint mixing machines

1. Mixing speed

The mixing speed plays a vital role in determining the efficiency and effectiveness of the paint mixing machine. It directly impacts how fast and thoroughly the paint components are blended. Consider the volume and frequency of mixing tasks for optimal results, and select a machine with a suitable mixing speed, typically ranging from 500 to 2000 rotations per minute (RPM). This makes it easy to achieve paint consistency and color in a reasonable time frame.

2. Capacity

Look for a machine with an average capacity that aligns with current requirements, usually ranging from 5 to 50 liters or more, depending on the model. The paint mixers must handle typical paint mixing tasks without overloading the machine or necessitating frequent batches.

Additionally, consider the available space in the workspace to strike a balance between the machine’s capacity and its fit within the operational area. This ensures smooth and efficient paint mixing operations that cater to production demands.

3. Cost

While the initial investment might decide, balance the cost and the machine’s features, performance, and durability. The prices of paint mixing machines can vary widely, with entry-level models starting around US$ 500 to US$ 1,500, while more advanced and larger-capacity machines can range from US$ 2,000 to US$ 10,000.

Opting for the cheapest option may save money upfront but could compromise performance and longevity. Investing in a higher-quality machine with a higher initial cost may be more cost-effective in the long run, as it will likely offer better performance and reliability.

4. Durability

Prioritize durability by selecting paint mixing machines crafted from robust materials capable of withstanding the rigors of continuous use and exposure to paints and chemicals. A machine with excellent durability can have an average lifespan of 5 to 15 years, depending on the quality and maintenance.

A durable machine will provide reliable performance and reduce the need for frequent repairs or replacements, ultimately saving valuable time and money in the long term.

5. Suitability

When buying a paint mixing machine, ensure they are well-suited for the specific types of paint or coatings they intend to mix. Different machines are designed to handle various formulations and viscosity levels. Some machines are ideal for water-based paints, while others excel with solvent-based coatings. Additionally, specific machines are optimized for high-viscosity materials, while others work better with low-viscosity ones.

6. Efficiency

Before buying a paint mixing machine, look closely at its efficiency, considering both power consumption and material wastage. An energy-efficient machine can significantly reduce operational costs as it consumes less electricity. This saves money and contributes to a greener and more sustainable operation.

Moreover, a machine that minimizes material wastage can substantially impact productivity and cost-effectiveness. Less wastage means fewer raw materials wasted, translating to cost savings and a more environmentally friendly approach.

Conclusion

Finding the right paint mixing machine is essential to ensure precise and efficient color mixing for painting projects. It’s crucial to consider factors like mixing speed, capacity, cost, durability, suitability, and efficiency to make a well-informed decision. To explore a wide range of paint mixing machines with various features and specifications, head over to Alibaba.com.