Lathe machines are an integral part of the manufacturing process as they help in woodturning and metalworking to shape wood, metal, and other materials into mainly cylindrical forms. This makes them crucial in crafting bowls, baseball bats, leg pieces of furniture, lamp posts, and much more.

When it comes to lathes there are mainly two variants—manual and CNC. While both are in high demand in the market today, they each have their own respective features, and as a result the ideal lathe will depend on the intended applications.

This blog will highlight the market outlook for lathes, and then it will explore the key difference between the two types to assist potential buyers with selecting the best possible machine for their needs.

Table of Contents

Market potential for lathes

What is a manual lathe?

What is a CNC lathe?

Manual vs. CNC lathes: key differences

The bottom line

Market potential for lathes

In 2022, the global market for lathes was around US$ 24 billion, and it is expected to reach US$ 32.7 billion by the year 2028, growing at a compound annual growth rate (CAGR) of 5% from 2023 to 2028.

The key factor to this growth is mainly the demand in the use of lathe machines worldwide for woodworking, metal spinning, thermal spraying, and many other industrial and manufacturing purposes. The main lathe machines that dominate the market are the manual and CNC variants.

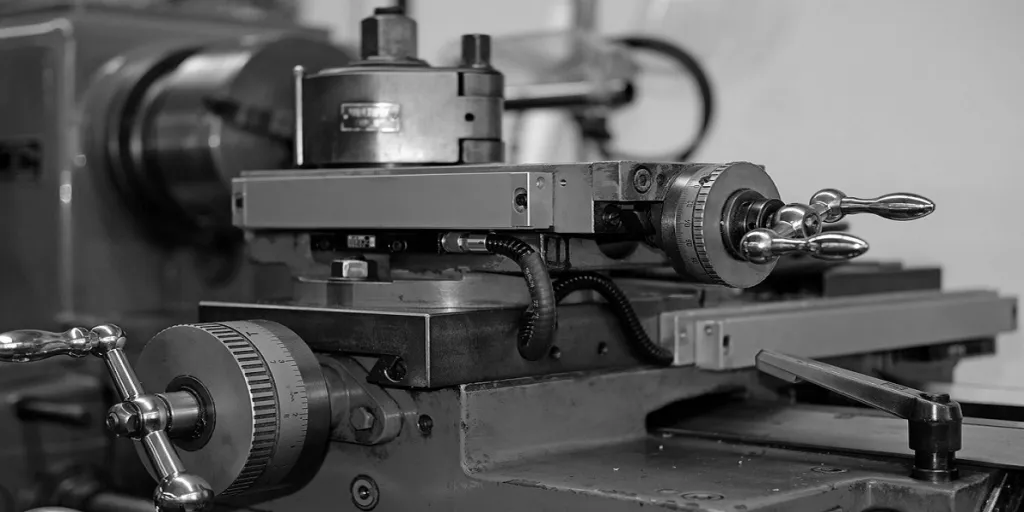

What is a manual lathe?

A manual lathe or otherwise known as a conventional lathe is mainly operated manually by an operator. It consists of a horizontal base or bed and the workpiece such as wood or metal is mounted there. The workpiece then gets rotated with cutting tools to shape the piece into a desirable form.

The major plus point of using a manual lathe machine is it offers versatility for operators when it comes to shaping materials into different shapes and sizes. You can find manual machines utilized across multiple industries such as woodworking, fabrication, and metalworking.

Based on the operator’s skill, it allows flexibility when it comes to precision turning, drilling, threading, and grooving operations. Many operators prefer this flexibility, and you can find these lathe machines useful for smaller-scale and specialized projects.

What is a CNC lathe?

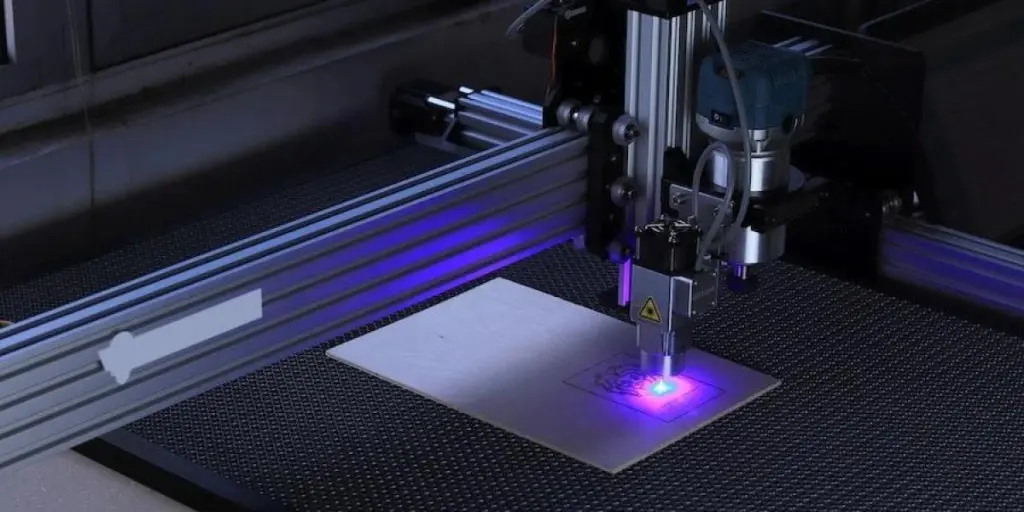

A CNC (Computer Numerical Control) lathe, unlike a manual lathe, is a computerized machine that automates the entire operational process. CNC lathes require instructions programmed in the system and then operate according to them.

Similar to manual lathes, CNC machines consist of a horizontal base, and are equipped with components for automation such as a control unit, CAD software, ball screws, servo motors, and a tool changer.

The major plus point of using CNC lathes is that they provide automation and precision in accuracy, which can be useful for large scale and repetitive processes because they offer enhanced productivity and consistency in quality based on programming sequences. You can find CNC lathes utilized in automotive, manufacturing, medical, and aerospace industries where automation is required.

Manual vs. CNC lathes: key differences

Now, let us look at the key differences between manual lathes and CNC lathes. They are widely differentiated based on the following factors:

Mode of operation

The first major difference is straightforward when it comes to its mode of operation. Manual or conventional lathes require an operator to manually use the machine to control movement and other parameters such as the feed rate and the depth of the cut. Therefore, it relies on the operator’s skills and learning curve to master the use of manual lathes.

CNC lathes, on the other hand, utilize computer programming and systems to control the automation of the whole operation and other parameters. As a result, operators can rely on inputting the right programming sequences instead of on their manual skills to operate CNC lathes.

Accuracy

When it comes to accuracy or precision, CNC lathes undoubtedly dominate this department because they remove human error as much as possible with their automated mode of operation. Despite the flexibility and freedom manual lathes offer, they can still be prone to human error depending on the operator’s skill level.

However, this doesn’t mean that CNC lathes are perfect because the end result still depends on the skill of the programmer in providing the right programming sequences for precise operation.

Efficiency

You will find CNC lathes to be more efficient when compared to manual lathes because they reduce errors and utilize materials properly without wasting them.

On the other hand, manual lathes depend on the operator’s skill, so they can be either highly productive or less efficient at times when compared to using computerized controls.

Cost

When it comes to costs, one needs to consider two points—initial costs and operating costs. When it comes to initial costs, there is no doubt that CNC lathes are much more expensive when compared to manual lathes.

Nevertheless, the operating costs of CNC lathes are much lower compared to manual lathes because CNC lathes don’t need operators to use the machine, and due to their high precision and efficient process, they can save operating and maintenance costs in the long term.

Product size and complexity

The maximum size of the workpiece that can be mounted depends on the base or bed size of both manual lathes and CNC lathes. One can find manual lathes available in different sizes, ranging from benchtop manual lathes to larger manual lathes for industrial purposes. Likewise, you can find CNC benchtop lathes and larger CNC lathes as well.

When it comes to the complexity of the projects, CNC lathes are better equipped for managing complex tasks and projects, whereas manual lathes are ideal for simpler operations and projects.

The bottom line

Despite their differences, both manual and CNC lathes are widely used across various industries.

In terms of finding the best solution, manual lathes are generally better suited for simpler manufacturing processes, whereas CNC lathes are better equipped for complex and repetitive tasks.

To explore quality listings of a range of lathes and other industrial equipment, head to Alibaba.com.