NMC batteries, with their high energy density, long life, and excellent charging performance, are gradually becoming stars in the electric vehicle industry. This means less charging time and longer driving distances, making your electric car an indispensable partner in daily life. Whether it’s for daily commuting or the occasional weekend excursion, NMC batteries provide stable and reliable power support. This article will give a brief overview of NMC batteries, and then it will highlight the key factors you should consider when selecting one in 2024.

Table of Contents

What is an NMC battery?

Further info for NMC batteries

NMC vs. lead acid: A performance analysis

What you should consider when selecting NMC batteries

Future developments in NMC battery technology

The bottom line

What is an NMC battery?

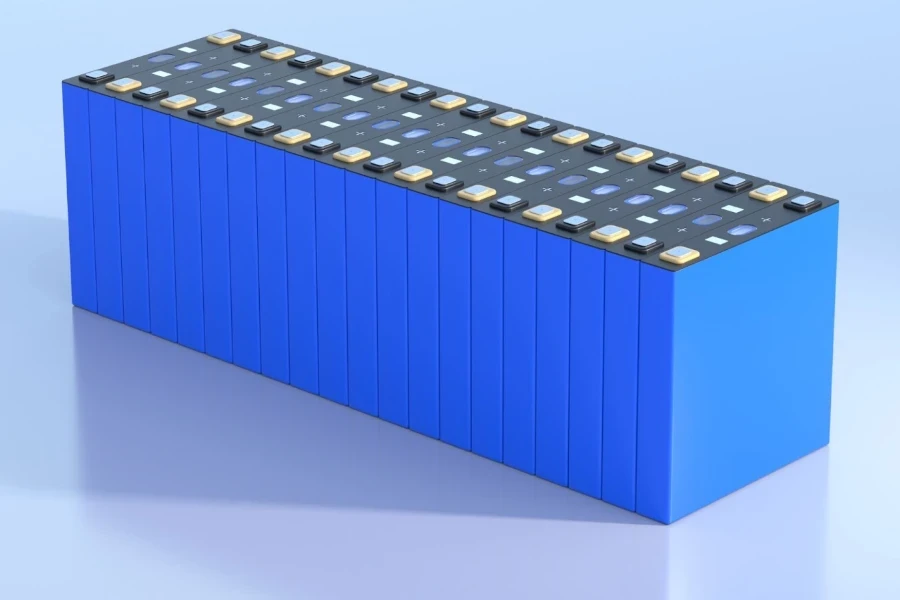

NMC batteries (nickel-manganese-cobalt batteries) are a popular rechargeable battery technology widely used in electric vehicles (EVs), hybrid electric vehicles (HEVs), portable electronic devices, and energy storage systems (ESS).

The core components of this type of battery include a positive electrode (composed of a mixed oxide of nickel, manganese, and cobalt), a negative electrode (usually graphite), and an electrolyte. The principle of operation is based on the movement of lithium ions between the positive and negative electrodes.

The lithium ions move from the positive electrode to the negative electrode during charging and store energy; when discharging, the lithium ions return to the positive electrode and release energy.

NMC batteries can be categorized according to the ratio of nickel, manganese, and cobalt. Common types include NMC111 (1:1:1 ratio), NMC622 (6:2:2 ratio), and NMC811 (8:1:1 ratio). NMC cells with different ratios differ in energy density, stability and cost. For example, NMC811 batteries offer higher energy density due to their higher nickel content, but may not be as stable and cost effective as NMC111.

Battery lifespan is typically affected by a variety of factors such as temperature, number of charge/discharge cycles, and charge/discharge rate, with typical NMC batteries lasting hundreds to thousands of charge/discharge cycles.

The cost of NMC batteries is affected by a variety of factors, such as raw material prices, manufacturing technology and market demand, so prices fluctuate widely. In terms of specifications and sizes, NMC batteries come in a variety of shapes and sizes, ranging from small batteries (e.g., for cell phones or laptops) to large battery packs (e.g., for electric vehicles).

With the advancement of technology and the expansion of production scale, the cost of NMC batteries is gradually decreasing and their performance is improving.

Further info for NMC batteries

Components of NMC batteries

Positive electrode material: the positive electrode is the core component of NMC batteries, which is made of mixed oxides of nickel (Nickel), manganese (Manganese), and cobalt (Cobalt). The ratio of these three metal elements can be adjusted according to specific application requirements, such as NMC111 (1:1:1 ratio of Nickel, Manganese and Cobalt), NMC622 (6:2:2 ratio) or NMC811 (8:1:1 ratio).

Nickel provides high energy density, manganese increases battery safety, and cobalt helps stabilize the chemical structure and improve the overall lifespan.

Negative electrode material: Negative electrodes are typically made from graphite or other forms of carbon materials. Graphite anodes provide a stable structure for storing and releasing lithium ions.

Electrolyte: The electrolyte is the conductive medium in the battery that allows lithium ions to move between the positive and negative electrodes during charging and discharging. The electrolyte is usually made from lithium salts (such as lithium hexafluorophosphate) dissolved in an organic solvent.

Diaphragm: The diaphragm is a thin, porous membrane placed between the positive and negative electrodes to physically isolate the positive and negative electrodes while allowing lithium ions to pass through. The material and pore size of the diaphragm have a significant impact on the performance and safety of the battery.

Shell and encapsulation: In order to protect the sensitive materials inside the battery and to ensure safe use, NMC batteries are encapsulated in a robust shell. The casing can be flexible (e.g. for cell phone batteries) or rigid (e.g. for electric vehicle battery packs).

Categorization

The classification of NMC (nickel-manganese-cobalt) lithium-ion batteries is mainly based on the proportion of the three elements nickel, manganese and cobalt in the cathode material. The difference in this ratio not only affects the performance of the battery, such as energy density, cycle life and stability, but also relates to cost and safety. Here are some common classifications of NMC batteries:

NMC111:

In this type of lithium-ion battery, the ratio of nickel, manganese, and cobalt is 1:1:1.

NMC111 batteries offer a good balance of performance, including moderate energy density, good cycle stability, and relatively low cost.

These batteries are widely used in products such as power tools and electric bicycles.

NMC622:

In the NMC622 battery, the proportion of nickel is increased to 60%, while the proportion of manganese and cobalt is reduced to 20% each.

The increased nickel content improves energy density, making this battery more suitable for applications with higher energy requirements, such as certain electric vehicles.

Compared to the NMC111, the NMC622 offers a significant increase in energy density, but may sacrifice some cycle stability and cost.

NMC811:

NMC811 batteries have a higher nickel content of 80%, while manganese and cobalt are each 10%.

This type of battery has a higher energy density and is suitable for applications that require higher range, such as premium electric vehicles. However, the high nickel concentration also poses greater challenges, including thermal stability issues and increased costs.

Application scenarios

NMC (nickel-manganese-cobalt) lithium-ion batteries have been widely used in a variety of fields due to their high energy density, long cycle life and good overall performance. The following are the main application scenarios for NMC batteries:

Electric vehicles (EV):

NMC batteries are very popular in electric vehicles, especially in vehicles that pursue high energy density and long range.

Portable electronic devices:

This includes smartphones, laptops, tablets, etc. These devices require small, lightweight batteries with high energy density, where NMC batteries excel.

Energy storage systems (ESS):

Solar or wind energy storage systems for commercial and residential use: NMC batteries provide the necessary energy density and cycling stability for long-term energy storage applications.

E-bikes and e-scooters:

These applications typically require lightweight and high energy density batteries, and NMC batteries meet these requirements.

Electric aerial vehicles and unmanned aerial vehicles (UAVs):

In aerospace applications such as UAVs, NMC batteries are widely used due to their high energy density and light weight.

Industrial and medical equipment:

In certain specialized industrial equipment and portable medical devices, NMC batteries provide the reliability and durability needed.

Public transportation and heavy transportation:

This includes electric buses and electric trucks, which require large capacity and high energy density batteries.

NMC vs. lead acid: A performance analysis

NMC batteries have significant performance differences from lead-acid batteries in terms of energy density, weight, life, charging speed, environmental impact, and cost. The following is a detailed analysis of the performance of these two types of batteries:

Energy density:

NMC lithium-ion batteries have high energy densities, typically around 150-220 Wh/kg, which means they can store more energy in a smaller volume and at a lighter weight.

In contrast, lead-acid batteries have a lower energy density of around 30-50 Wh/kg. This results in lead-acid batteries being larger and heavier for the same energy storage requirements.

Weight and size:

Due to higher energy density, NMC batteries are lighter and smaller than lead acid batteries for the same energy output. This makes NMC batteries more suitable for applications that require lightness, such as portable electronic devices and electric vehicles.

Longevity:

NMC batteries typically have a longer lifespan of 1,000 to 2,000 charge/discharge cycles or more.

Lead-acid batteries have a shorter cycle life, typically in the range of 300 to 500 charge/discharge cycles.

The longer life of NMC batteries means longer replacement cycles and may be more economical in the long run.

Charging speed and efficiency:

NMC lithium batteries can be charged quickly and more efficiently than lead-acid batteries.

Lead-acid batteries have a slower charging process and charge less efficiently.

Environmental Impact:

Lead-acid batteries contain highly toxic lead and acidic substances that pose potential risks to the environment and human health.

While NMC batteries are more environmentally friendly, there are environmental and social issues associated with the mining and processing of lithium, cobalt and nickel.

Cost:

Lead-acid batteries are usually cheaper than NMC batteries in terms of initial purchase cost.

However, from a long-term use and maintenance perspective, NMC batteries may have a lower total cost of ownership (including replacement frequency, maintenance costs, etc.).

Overall, NMC batteries outperform lead-acid batteries in terms of energy density, weight, lifespan, and charging performance, making them more suitable for applications with high performance and portability requirements.

However, lead-acid batteries still have their advantages in terms of cost and certain industrial applications. As battery technology continues to advance, NMC batteries are becoming more cost-effective and are gradually replacing traditional lead-acid batteries in more areas.

What you should consider when selecting NMC batteries

Energy demand and density: When high energy output or long range is required, such as in electric vehicles, it is more appropriate to select NMC batteries with high energy density.

Size and weight constraints: For applications with size and weight constraints (e.g. portable electronic devices), a lightweight NMC battery would be a better choice.

Cycle life: In cases where frequent charging and discharging is required (e.g., energy storage systems), it is more economical to choose an NMC battery with a longer cycle life.

Cost: While the initial cost of NMC batteries may be higher than other types of batteries, their long-term operating costs and replacement frequency are lower.

Fast charging capability: In cases where fast charging is required, it is more appropriate to select an NMC battery that can support fast charging.

Future developments in NMC battery technology

Increasing energy density:

Through improvements in battery chemistry and structural design, future NMC batteries will pursue higher energy densities, leading to longer ranges in applications such as electric vehicles, while reducing battery size and weight.

Reduced reliance on cobalt:

Cobalt is a scarce and expensive material, and the process of mining it often involves environmental and human rights concerns. Therefore, reducing or eliminating the use of cobalt in NMC batteries is an important research direction to reduce costs and improve battery sustainability.

Improving cycle stability and lifetime:

Researchers are working to improve the cycle stability and overall life of NMC batteries, which will reduce the frequency of replacements and lower the long-term cost of use.

The bottom line

NMC batteries are high-performance rechargeable batteries known for their high energy density, longevity, and good overall performance. This battery consists of a mixed oxide of nickel, manganese, and cobalt as the positive electrode material, graphite as the negative electrode material, and uses a lithium salt solution as the electrolyte.

It is widely used in a variety of fields, including electric vehicles, portable electronic devices, energy storage systems, electric bicycles and electric scooters, drones, and industrial and medical equipment.

Finally, if you are interested in exploring a range of NMC batteries for home and business use, check out the extensive list of product offerings on Alibaba.com.