Remember those products that came in shiny packaging? That was the result of foil stamping. This printing technique is an effective and creative way for retailers to offer their products, ensuring consumers get attracted at first sight.

Whether sellers want to add a luxurious feel or create an eye-popping visual, foil stamping is the key to making their custom packaging stand out.

Explore this ultimate guide to learn everything about foil stamping and how to maximize its effect in 2024.

Table of Contents

What is foil stamping?

How does it work?

What benefits make foil stamping worth it?

What are the different types of foil stamping?

When should businesses use foil stamping?

Final words

What is foil stamping?

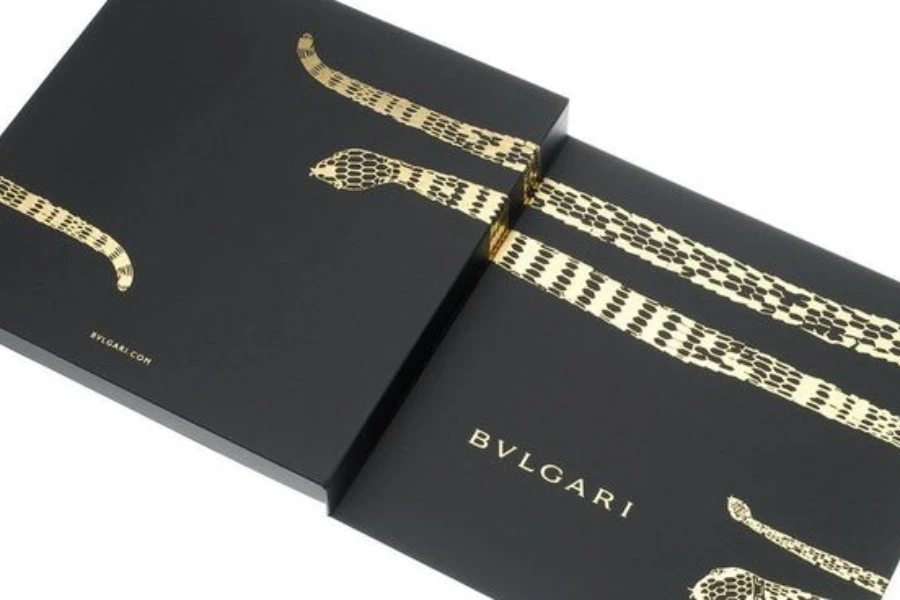

Foil stamping is a printing technique that injects style and sophistication into any paper product—or, in this case, packaging. This process includes applying metallic or pigmented foil to a substrate, like paper or cardstock, resulting in a captivating design and a glossy finish.

This unique technique dates back to the 19th and 20th centuries and was popular for decorating book covers. Now, foil stamping has become one of the most popular printing methods for packaging. Businesses love it because it helps create custom logos or text without additional costs.

Unlike digital presses and conventional printing methods, foil stamping introduces a distinctive texture, providing printed items with an elegant touch that effortlessly grabs the consumer’s attention.

How does it work?

Foil stamping involves using a metal die and pressure to print a catchy image on a surface. First, pressure is applied to the metal die, engraving the logo or design to be printed on its surface. Then, the next step stamps the image on the desired texture.

Basically, businesses can use two types of foil stamping techniques to create amazing stamped images. Here’s a deeper look at how these techniques work.

Hot foil stamping

Hot foil stamping is a type of embossing that uses a heated metal object to create a raised design on a surface. The heated object is placed on the item and pressed against it with a roller to stamp the desired design onto the surface. It’s a simple way to add texture and detail to packaging.

Although hot foil stamping works for most packaging materials, it produces better results on softer and more flexible ones (like leather, fabric, and vinyl).

Cold foil stamping

Cold foil stamping is similar to its hot counterpart but with one key difference—it utilizes cold water instead of heat. This difference creates a different style, as cold water absorbs more ink than heat.

This technique is common for crafting logos or patterns on clothing, packaging, and other materials. It usually involves rubber instead of ink stamps, creating a cleaner and less messy alternative.

What benefits make foil stamping worth it?

Versatility and customizability

The best part about foil stamping is its versatility. They can embellish various packaging types, including paper, plastic, glass, and metal. And retailers can choose from multiple colors and textures to create something special—they can even collaborate with artisans to bring their unique ideas to life.

Customizability is also a major benefit of foil stamping. It grants designers and product creators enough flexibility to add subtle yet distinct design elements, directing the customer’s focus to the desired message. With foil stamping, nothing is out of reach.

Unique look and feel

Foil stamping offers a unique aesthetic and tactile experience that businesses can’t get with other printing methods. It instantly enhances the appearance of packing boxes, making them look more attractive.

More importantly, foil stamping gives packaging an elegant feel, increasing its value and making it more appealing to consumers. It’s a no-brainer for businesses into luxury products, as the technique helps create a sense of opulence around the delivered product or packaging.

Compatibility with other printing techniques

Businesses can easily pair foil stamping with embossing or debossing techniques. Using embossed foil stamping, retailers can create a 3D raised surface or image resist to attract the eyes.

On the other hand, debossed foil stamping creates a receding effect, creating a sinking or indented look on the metallic design. Both techniques are crucial for adding texture and eye-catching styles to product packaging with foil stamping.

Durability and longevity

Foil-stamped designs are resistant to the test of time. While traditional printing methods (laser or inkjet printing) fade over time, foil stamping produces an effect that won’t fade or scratch, meaning it’ll maintain its original look for extended periods of time.

Therefore, foil stamping is a fantastic option for businesses searching for long-lasting packaging solutions.

What are the different types of foil stamping?

Metallic foil

If a luxurious look is what retailers want, then gleaming metallic foil is their best bet. This foil type creates an attractive finish in shades of blue, green, silver, red, gold, and copper.

But that’s not all. Metallic foils have a unique property that offers different aesthetics depending on the angle consumers view them from. In other words, light adds a special depth effect that changes according to perspective.

Whether sellers want large textured swirls or a classic matte look, the versatile metallic foil will make it stand out.

Holographic foil

Looking for something even more dazzling than metallic foil? Try holographic! Regarding creative and artsy packaging, holographic foil takes the spotlight. It effortlessly turns images into vibrant 3D holograms, giving products an ultra-modern edge.

But the real showstopper is the mesmerizing rainbow effect popular with anything holographic. This foil’s unique shine makes it perfect for retailers prioritizing packaging with a splash of color.

Pigment foil

Pigment foil opens the doors to a versatile spectrum of colors and finishes, ranging from the understated matte pigment to the lively glossy (non-metallic) ones. The best part is that each one offers a distinctive shade with rich depths.

For instance, matte offers a subtle touch, while gloss delivers strikingly vibrant color combinations that shine from every angle. Pigment foiling looks and feels amazing on various materials, from paper to plastic.

When should businesses use foil stamping?

Before retailers decide if they need foil stamping, they must determine if they want consumers to focus on something specific, like logos or icons. If they do, then foil stamping is the best way to make eye-catching designs and luxurious feels.

But that’s not all. Foil stamping can also emphasize specific keywords or phrases within the packaging design. However, avoid making the prints too distracting.

For foil stamping, businesses should use a simple color palette and subtle metallic backgrounds. That way, the packaging will look modern and stylish without obstructing the message the retailer wants to communicate.

However, if sellers want maximum impact, they can experiment with multiple foils. It’s an excellent way to blend various textures and colors beautifully.

Final words

Foil stamping offers various advantages that make it a fantastic choice for any product packaging. Its effects are stylish and long-lasting, making it the perfect solution for businesses’ creative needs.

So, if businesses need ways to stand out from the competition or want to highlight something specific about their products, foil stamping is the way to go. So don’t hesitate! Start making those attractive packaging and get consumers talking in 2024.