Soldering stations cater to many essential needs in the electronics manufacturing industry. They have evolved over the years in tandem with technological advancements. Some soldering stations can also be used as desoldering tools and may include special extensions to make overall operations easier. Continue reading to find out more about the essential components of soldering stations.

Table of Contents

Market analysis of soldering stations

What is a soldering station?

Types of soldering stations

What to consider when selecting soldering stations

Conclusion

Market analysis of soldering stations

The soldering equipment market is expected to grow at a CAGR of 9.56% to reach USD 911.3 million by 2030. Soldering is used in various industries, including automotive, medical, musical instruments, mobiles, and computers. The rapid growth of the electronic industry has facilitated the development of the soldering stations and accessories market.

The growth can also be attributed to rapid industrialization and the use of advanced soldering in different types of machinery. The top players in the market are Weller Tools, Kurtz Holding, and Jameco Electronics, among others, and the Asia Pacific region is anticipated to be the largest market.

What is a soldering station?

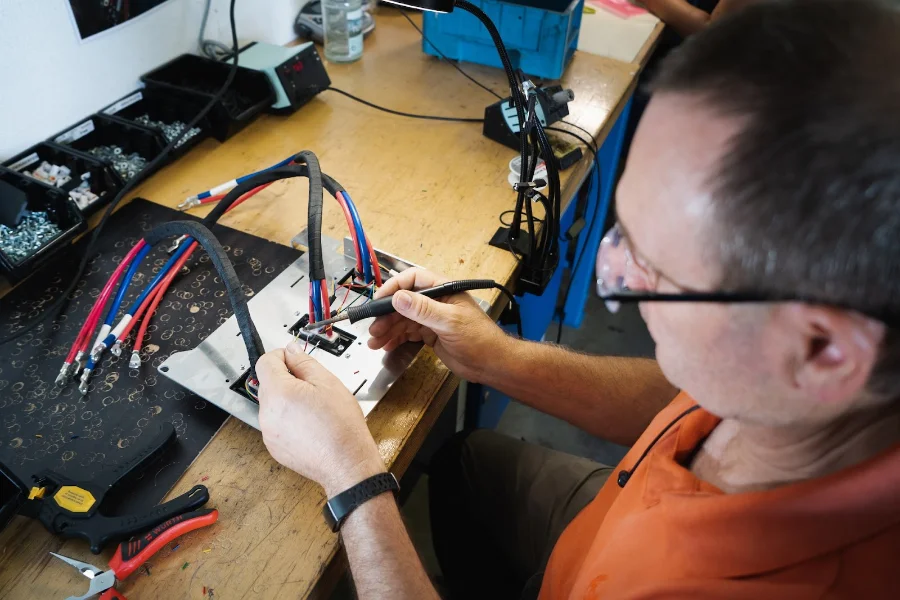

A soldering station is an electronic device used to solder electronic components to a printed circuit board (PCB). It comes with a temperature control feature and a soldering iron. The majority of soldering stations have temperature control settings and are primarily used in PCB electronic assembly and manufacturing plants. They are also used to repair electronic devices and overhaul circuit boards.

Before we go any further, let’s look at the various soldering stations and discuss their characteristics and applications.

Types of soldering stations

Contact soldering stations

These are the most popular type of soldering station and differ slightly from the traditional options. However, some features could be improved—as they are unable to adjust the temperature of the heater, they frequently overheat the sensing element. Contact soldering stations have an integrated power supply unit and can heat up to 400°C.

Users can change the heating temperature by adjusting the voltage of the heating element via the power supply unit. In most cases, the ideal soldering temperature range is between 250°C and 330°C.

Hot-air soldering stations

A hot air soldering station is equipped with a compressor that generates air flow, which is heated to a specific temperature. This airflow generated by the heat gun is directed toward the soldering area. With several heating pads available, this is the ideal solution for soldering in limited space.

They are popularly used to repair cell phones and other household items. This soldering station is compatible with both lead and lead-free alloys. Its applications, however, are quite limited. For instance, it cannot be used to solder or desolder large BGA chips.

Digital and analog soldering stations

Digital soldering stations let users control the temperature via digital settings. They have a digital display that shows the set temperature and provides greater accuracy and tolerances. They are also less expensive than analog soldering stations.

On the other hand, analog soldering stations are outfitted with a knob for controlling the temperature. Unlike their digital counterparts, they do not have a display screen to show the set temperature. Furthermore, the temperature settings are not very accurate. They are appropriate for small tasks such as mobile repairs, among other things.

Anti-static soldering stations

Soldering stations can be either ESD (electrostatic discharge) safe or not. The static charge on the iron will not accumulate in the ESD-safe stations, as the excess electrical energy will be quickly discharged into the ground. Most modern electronic devices, such as smartphones, require ESD-safe soldering stations because they contain electronic components sensitive to static electricity and can easily be damaged.

Lead and lead-free soldering stations

Most manufacturing companies are turning toward lead-free options. Lead-free soldering stations operate similarly to traditional counterparts but differ in heating element power, which ranges from 75-80 W to 150-160 W. The melting point of lead-free solder wire is 217°C to 221°C, and that of lead solder wire is 183°C.

Therefore, a soldering station with a power output of 50 W to 60 W is more than adequate for soldering lead solder wire. However, a powerful soldering station is required for lead-free soldering.

What to consider when selecting soldering stations

Temperature control

A flexible soldering station with a wide temperature range is required to work on different projects. Certain tasks will be difficult to complete if a unit has a fixed temperature. So look for versatile options with a thermostat that automatically turns off the heater once it reaches the temperature the user has set.

A thermostat is helpful because it allows users to adjust the temperature to the exact amount required by the project. If this feature is missing, the iron will continue to heat until the PTC switch turns it off, which may not provide enough heat for certain projects. Another thing to consider when it comes to temperature is consistency. Once it reaches the desired temperature, the ideal soldering station should be able to maintain the temperature consistently.

Wattage

Although the wattage varies between models, choosing a device that is easy to operate and has a wide temperature range is essential. Some devices use 40 W, while others use up to 80 W. When evaluating a soldering station, the rule of thumb is that a higher wattage makes complex tasks much easier to complete.

Thermal recovery

It is best to choose soldering stations with high thermal recovery, especially for frequent soldering. Soldering stations with low thermal recovery cause issues like cold solder joints. In contrast, a heat-recovering feature will notify the soldering station of how long it takes for the soldering tip to reach the desired temperature.

Soldering iron tips

Soldering irons have interchangeable tips in chisel and conical shapes and are mostly made of copper and nickel solder. They are available in various sizes and can be used to complete different tasks. The soldering tips can affect how well you solder, with each tip having its advantages and disadvantages. So, before purchasing a soldering tip, consider its compatibility with the soldering station.

Aside from compatibility, another factor to consider is the tip shape. A chisel tip is ideal for beginners because it has a flat surface that is easy to hold and use. Hoof tips are an excellent choice for advanced users and for drag-soldering multiple surface mount pads. They are great for complex soldering projects, especially when used with the appropriate soldering station. Among all the types of tips, conical tips are the most difficult to use but also the most precise.

Another factor to consider is the material of the soldering tips. Iron is much cheaper and robust but cannot retain or transfer heat as effectively as copper tips. High-end soldering tips have an iron-coated copper tip, providing the most competent option.

Maintenance

When using a soldering station, it is important to evaluate whether the spare parts can easily be obtained. Although the soldering iron can be used for many years, the soldering iron bits have a shorter life span and may require a replacement periodically, depending on the usage.

Conclusion

As previously discussed, soldering stations have all the tools required to work on circuits and make repairs. The market is flooded with different soldering station options, and this article glosses over the major types, their functional characteristics, and their applications. Visit Alibaba.com to check out the latest soldering devices available today.