As the demand for vegetable oil rises in our industrialized society, oil presses have become an increasingly popular piece of equipment that has found a place in both home and manufacturing applications. But how can buyers know which oil press is best for their business? There are so many options out there that it can be hard for businesses to figure out which ones will work best for their specific needs. In this guide, we’ll go over how to pick the best-suited oil presser depending on various key factors.

Table of contents:

Why the market of oil presses is set to explode

3 types of oil presses you should know about

4 factors to consider when choosing an oil press

Choosing an oil press is a critical decision for businesses

Why the market of oil presses is set to explode

Vegetable oils are obtained from the seeds, fruit, nuts, and leaves of various plants. These oils have a wide range of applications in various industries including food, pharmaceuticals, biofuels, and many others.

The global vegetable oil market size is estimated to reach $3,700 million by 2026, growing at a CAGR of 6.1% over 2021-2026. The rising demand for vegetable oils from these industries is expected to drive the global demand for oil pressers.

By type, the soyabean oil segment is estimated to register the fastest CAGR of 1.05% for the period 2021-2026 owing to its high-fat content and low price as compared to other vegetable oils.

In terms of geography, Asia Pacific dominated the vegetable oil market with a major share of 40% in 2020, followed by North America and Europe. Meanwhile, North America is estimated to dominate the market by a CAGR of 3.05% over the upcoming years, owing to rising research and development activities in the food and beverage industry.

3 types of oil presses you should know about

Manual presses

Manual oil presses, also known as hand-operated pressers, are the simplest and cheapest type of oil press. As their name suggests, these presses are operated manually. This is the most labor-intensive of all the types of oil presses, as it requires a significant amount of time and effort to press the seeds. Although portable and cost-effective, their small size makes them suitable for household extraction only.

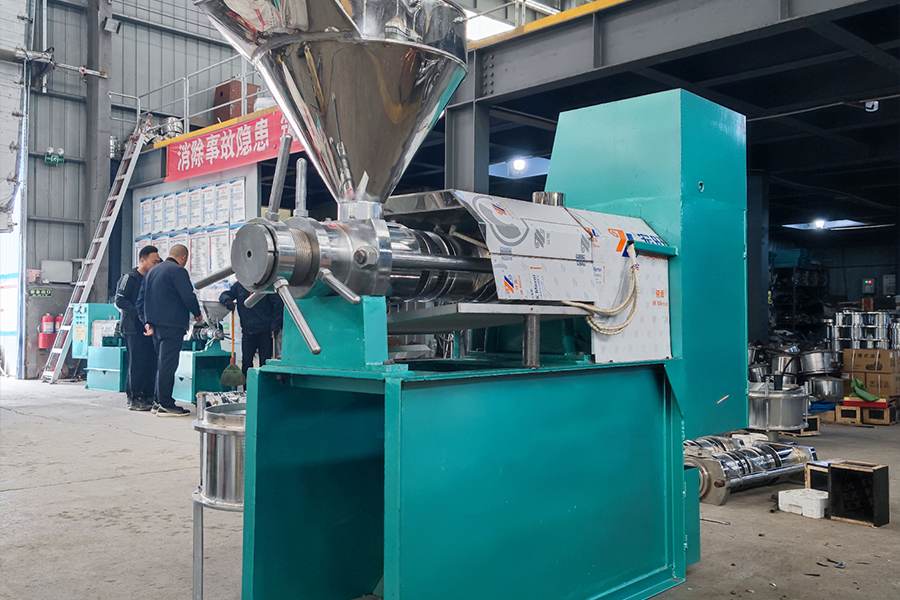

Screw presses

Screw presses are one of the most popular types of oil press, mainly because they serve as a great introduction to the world of oil extraction for small businesses. They’re widely used to extract oil from a range of different materials, including soybeans, sunflower seeds, peanuts, and more. They work by crushing or shredding the raw material into a paste, which is then expelled under high pressure to extract the oil. The oil gets collected in a collection chamber at the bottom of the presser, where it can be drained off. Screw presses are especially good for extracting oil from raw materials that are fibrous or require some kind of grinding before they’ll release their oil.

Hydraulic presses

Hydraulic oil presses are a type of oil presser that utilizes liquid pressure to force an oil-containing product through an opening. There are two main types of hydraulic oil pressing: cold pressing and hot pressing. Cold pressing is done at room temperature to maintain the nutrients and flavor of the oil, while hot pressing is done at a higher temperature to increase the oil extraction yield; although both methods are effective, cold pressing is normally preferred, as it preserves the flavor and nutritional value of the oil.

4 factors to consider when choosing an oil press

Raw materials

When choosing an oil press, the crop type is one of the first things to consider. This is because each vegetable seed has its unique properties, from its size and texture to the amount of oil it contains. While most presses are versatile and can be used for almost any type of plant, some models will perform better with certain types of seeds than others.

For soybean processing, it is recommended to choose an oil press that can handle materials with tough exteriors, like for example the full-automatic oil expeller. This is because soybean hulls are fairly dense and need to be removed before extraction can begin. As opposed to soybeans, the sesame seeds are soft and oily, which means they require less pressure when squeezed. For such types of vegetable materials, a home-based oil press machine will be sufficient and cost-effective.

Generally speaking, materials that are high in fiber content require more pressing power as well as more pre-processing time before extraction can take place. Nuts like walnuts or almonds also need more power because their hard outer shells protect the soft meat inside; for these types of nuts, a more advanced model such as the hydraulic cold-and-hot press machine would work best.

Output demand

Another factor to consider when selecting an oil press is the output demand. Businesses need to determine how much oil they’ll be producing, and how much extraction capacity they need to meet their market demand.

For example, home-based oil pressers are highly recommended for those who are just processing a small amount of oil for personal use. These extraction machines are usually smaller and less expensive than their large-scale counterparts, and they can be used manually or with an electric motor.

Alternatively, the small-scale cold press is an ideal entry-level machine for businesses who want to experiment with different kinds of oils without making larger investments in heavy-duty equipment. The aforementioned machine can also be used in small spaces, like a loft or storage unit, and it’s portable enough to be taken to different locations if needed.

But for those who are focused on producing large amounts of oil for their business, a large-capacity oil extraction machine is the best way to go. This machine is capable of processing up to 1,000 tonnes of raw material per 24 hours, which is typically enough capacity to meet the demands of large-sized businesses.

Squeezing method

The squeezing method is a crucial element of the oil extraction process. Cold pressing machines involve extracting oil by simply crushing seeds or nuts. This method allows the oil to retain its flavor, aroma, and nutritional value since it is not exposed to heat or chemicals during the extraction process.

Hot pressing machines, on the other hand, involve applying heat—up to 120 degrees Celsius—to increase the yield of oil that can be extracted from a given amount of nuts or seeds. This method is typically used for seeds and nuts with low oil content.

For instance, walnut seeds require an oil press that works at a very low temperature, such as the cold screw oil press, because walnut oil is rich in polyunsaturated fatty acids, which can be oxidized and turn rancid if exposed to high temperatures. On the other hand, olive oil is rich in monosaturated fatty acids and can be extracted and processed at higher temperatures using engine-driven extraction machines without being oxidized.

Filtering system

The last thing that should be taken into account when choosing an oil press is the filtering system. There are two main types of filtering systems: centrifugal filters and vacuum filters.

Oil presses with centrifugal filters are easier to operate than those equipped with vacuum filters. Indeed, a centrifugal oil filter is easier to operate because it is self-cleaning. When oil passes through the filter, the centrifugal force causes impurities to settle on the floor of the filter. Once the filter is full, it begins emptying itself into a chamber. From there, oils and impurities can be separated and collected.

Oil pressers with vacuum filters, on the other hand, require more manual labor than a centrifugal filter, as they must be cleaned after each use and charged with solvents for optimal performance. However, it takes less time for oils to be filtered out using this type of filtration system.

Choosing an oil press is a critical decision for businesses

Choosing the right oil press is a critical decision that can determine the success of vegetable oil production businesses. Business buyers have to choose an oil press that can process their raw materials, produce the volume of oil they need, and suit their particular business model, whether it’s small- or large-scale. This buying guide is designed to provide businesses not just with purchasing tips, but also with a comprehensive list of the best oil presses available on Alibaba.com.