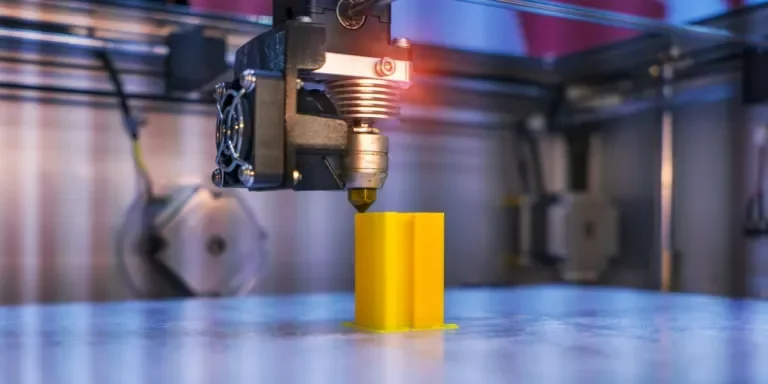

3D printing (additive manufacturing) has transformed industries by creating complex structures in layers. Once only used in rapid prototyping, 3D printing has extended to general manufacturing in different industries. With the ongoing technological advancements, 3D printing is shaping the future of production.

As more industries adopt 3D printers, small businesses and retailers should take advantage and stock 3D printers and their accessories in their inventory. 3D printers offer on-demand production and customization of components, changing the supply chain landscape.

This article will give you an overview of 3D printers, their applications, and key predictions. Read on to learn more about the future of 3D printers.

Table of Contents

Market overview

Niche applications of 3D printing

Art and fashion

Culinary innovations

Bioprinting

The role of AI and machine learning in 3D printing

The future of 3D printing

Conclusion

Market overview

In recent years, more industries have adopted 3D printers, exponentially expanding the 3D printing market. According to Fortune Business Insights, the global 3D printing market was valued at USD 23.41 billion in 2025 and is estimated to grow to USD 101.74 billion by 2032, with a compound annual growth rate (CAGR) of 23.4% during the forecast period.

This growth is attributed to the increase in digitization and adoption of advanced technologies in different industries, from automotive and aerospace to healthcare. The increase in smart factories, robotics, and machine learning has also contributed to the adoption of 3D printing technology.

3D printing streamlines the supply chain by:

- Reducing dependency on traditional manufacturing: When one locally prints the parts and components they need, they reduce the lead time and transportation costs.

- Enhancing inventory agility: You only create items on demand and reduce the need for large inventories, reducing the holding and storage costs.

- Enhancing innovation: 3D printers can create anything, and one can experiment and create custom parts quickly and easily, thus reducing the time to market.

- Customizing: You can adapt the products to specific customer needs.

- Sustainability: 3D printers reduce waste and optimize material usage, making them environmentally friendly compared to traditional manufacturing.

Niche applications of 3D printing

For many years, 3D printers were used to print prototypes to reduce the time and cost in product development. They were also used for personalization and custom manufacturing for instance, in the healthcare industry for dental implants and prosthetic limbs.

The applications for 3D printing have evolved, and there are emerging niche applications. Some of these applications include:

Art and fashion

Artists and fashion designers are using 3D printing technology to push creativity boundaries. This technology allows intricate and unconventional designs that were impossible to create with traditional methods. Fashion designers are experimenting with 3D-printed clothes, shoes, and accessories, providing a glimpse into the future of wearable technology.

Culinary innovations

The food industry is also embracing 3D printers to create customized food products. 3D technology in the food industry is as exciting and innovative. Chefs are blending their culinary skills with 3D technology to create 3D-printed food. The food tastes like regular food as it is made using regular ingredients, but has a unique texture and shape, bringing the chef’s creativity to life.

Bioprinting

3D printing is gaining popularity in all industries, and in the healthcare industry, it is being used to create replacement body parts like ligaments, tendons, and cartilages. In the future, it is expected that the advancement in 3d printing technology will help in the production of other human organs. Bioprinting will help improve patients’ lives and reduce the risk of organ rejection. It will also remove the need for human organ donors in the future.

The role of AI and machine learning in 3D printing

AI and machine learning are transforming how 3D printing technologies work. They help enhance workflow, improve quality, and enhance efficiency. The roles of AI and machine learning in 3D printers include:

- Quality control: AI algorithms monitor and analyze 3D printers in real time to detect any errors in the designs or issues during printing, allowing immediate adjustments and preventing defects.

- Process optimization: Machine learning algorithms learn from historical data to identify the optimal printing parameters for specific materials and designs. This leads to better product quality and reduced waste.

- Material selection: The AI algorithm analyzes the properties of different materials and their printing requirements to select the most suitable materials for a given application.

- Defect detection: In critical 3D printing applications like aerospace or healthcare, machine learning algorithms can be used to identify defects in the printed components, ensuring high-quality components.

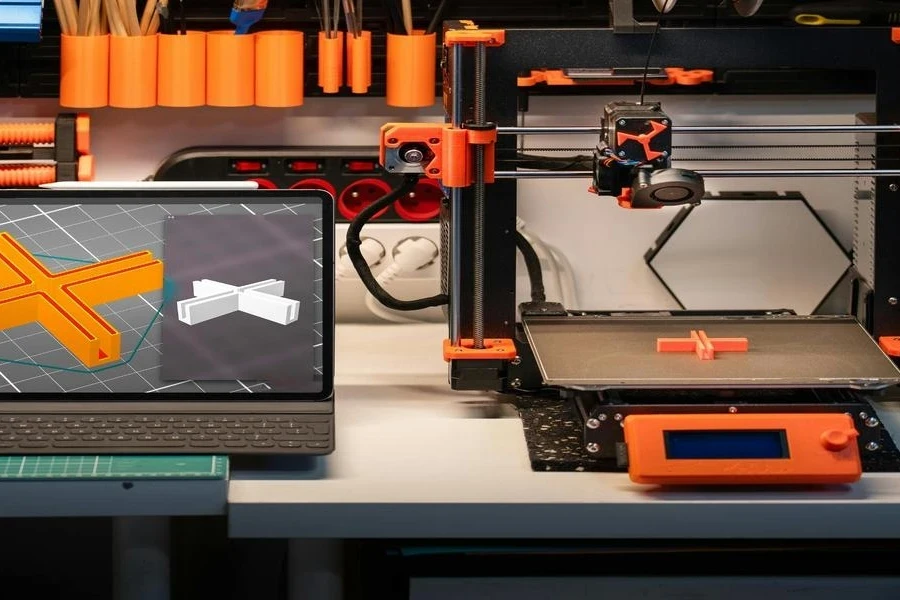

- Customization: AI-powered tools can create complex designs for 3D printers and customize the parts for specific applications.

- Efficiency and workflow automation: AI automates 3D model layers to improve efficiency and accuracy. In addition, it analyzes data from 3D printers to predict issues before they occur, reducing downtimes and optimizing resource usage.

The future of 3D printing

The future of 3d printing is filled with endless possibilities. With more people using 3D printers for various applications, the sky’s the limit. One of the exciting developments we expect to see in the future is mass customization.

As 3D printers become more accessible, consumers will demand custom-made items to suit their preferences. This shift from mass production to mass customization will revolutionize fashion, consumer electronics, and other industries.

Additionally, integrating 3D printers with other technologies, like the Internet of Things (IoT), will open up new innovations. For instance, IoT-enabled 3D printers can communicate with other printers to optimize production schedules.

Conclusion

3D printing is no longer a futuristic concept. 3D printers are here and actively changing industries, improving sustainability and lives. The potential of 3D printing technologies is endless, and they continue to push technology boundaries.

With the 3D printers’ impact increasing worldwide, small businesses should embrace them to improve their productivity, reduce lead time to market, and reduce waste in their production. They will also be able to customize customer items, making them the go-to for personalization and increasing their customer base and revenue.

Harness the power of 3D printers and help build a more sustainable and innovative world.