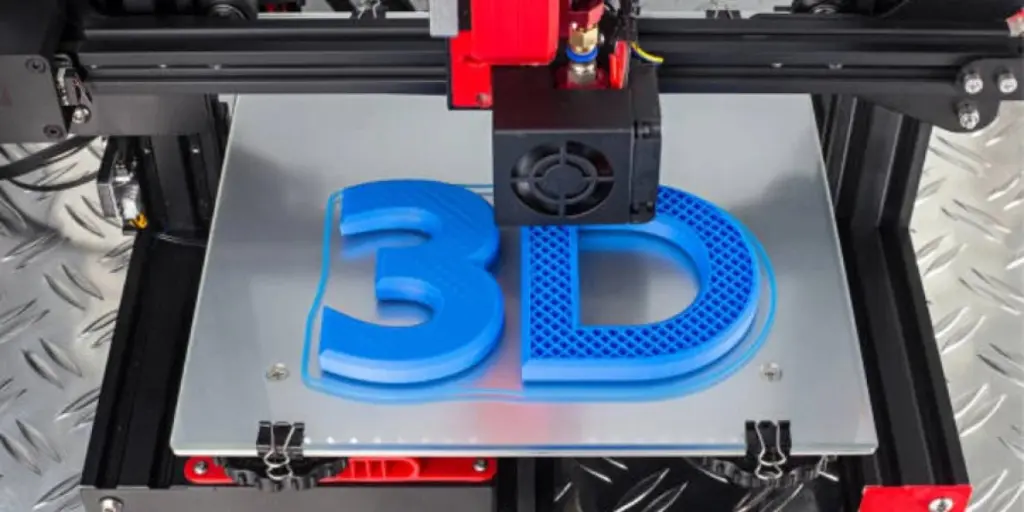

3D printing technology is one of the many advanced and most loved trends in the printing industry. The method comes with so many benefits including reduced waste of raw materials, reduced costs, printing on demand, and the ability to create flexible designs. To get the best results, there is a need to use suitable materials for 3D printing. The list of materials used in 3D printing is growing big and you need to understand each of them well before deciding on which one to use.

This article will look at the different types of materials used in 3D printing. Additionally, it will dig into the 3D printing market size and growth.

Table of Contents

3D printing market size and growth

Suitable 3D printing materials

Conclusion

3D printing market size and growth

There has been significant growth in the 3D printing technology market facilitated by its adoption in various industries for simulation purposes. Some of these industrial uses include robotics, smart factories, and machine learning. The technology has also been utilized in the healthcare, automotive, and aerospace industries, among others.

According to Fortune Business Insights, the global 3D printing market revenue was estimated to be USD 15.10 billion in 2021. It was further projected to expand from USD 18.33 billion in 2022 to USD 83.90 billion by 2029, exhibiting a compound annual growth rate of 24.3%.

The main driving factor for this significant growth in demand for 3D printing is the substantial investments made by various governments. Additionally, several technological giants are including this technology in their manufacturing processes. The competition among countries like the United States, Korea, China, and India to maintain complexity in manufacturing has also fostered market growth.

Regionally, the global market is divided into five major areas. They include South America, North America, Europe, Asia Pacific, and the Middle East & Africa. North America registered the largest share in the international market with Europe coming second. This was ascribed to the rising expenditure on advanced manufacturing technologies.

Suitable 3D printing materials

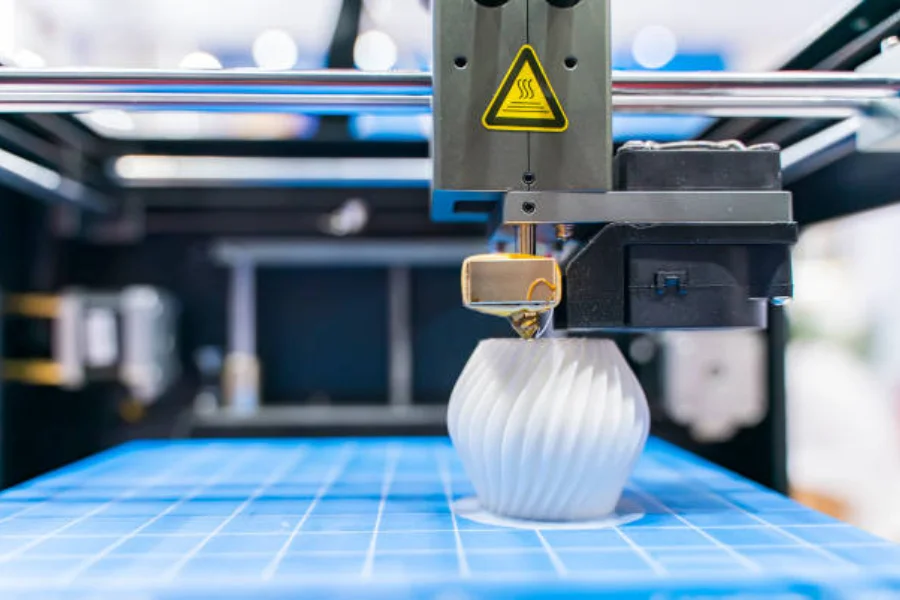

1. Plastic

Plastic is a widely used raw material for 3D printing. It is applied to household items and toys. Some of the products with this technique include vases, utensils, and action figures. Some of them are available in colored designs while others are transparent.

Plastic is smooth, flexible, and firm and has a wide range of color options. Buyers will also find this material to be light, appealing, and easily affordable. Most plastic products are made by FDM printers, where the thermoplastic filaments are melted and molded into the desired shape.

There are various plastic materials used in the printing process, including;

– Polylactic Acid (PLA): It is the eco-friendliest option used in 3D printing. PLA is sourced from natural products like corn starch and sugar cane; thus it is biodegradable. It is available in hard and soft forms. Hard PLA is used for a broader range of products.

– Polyvinyl Alcohol Plastic (PVA): It is used on low-end household printers to support materials with dissolvable varieties. It is a low-cost option used for temporary-use items. Therefore, it is not suitable for products that require high strength.

– Acrylonitrile butadiene styrene (ABS): It is also called LEGO plastic and is valued for its strength and safety. The material has pasta-like filaments that enhance flexibility and firmness. It is widely used on home-based 3D printers to give products like toys and stickers. Due to its availability in various colors, it is also used in making vases and jewelry.

– Polycarbonate (PC): It is less frequently used compared to other types of plastics. This is because it only works with 3D printers with nozzle designs that operate at high temperatures. PC is used to make low-cost plastic fasteners and molding trays.

2. Metal

Metal is ranked as the second-most-used material in 3D printing materials as it produces a diverse range of strong items. It is used through a process called direct metal laser sintering (DMLS). DMLS printers manufacture products in aerospace equipment, construction parts, and jewelry.

Below are some of the metals applicable to the DMLS technique and their subsequent products:

– Bronze – vases and other fixtures

– Stainless steel – utensils and other cookware items

– Gold – earrings, rings, necklaces, and bracelets

– Aluminum – thin metal objects

– Nickel – coins

– Titanium – strong and solid fixtures

3. Carbon fiber

Carbon fiber is a composite used in 3D printing as a top coat over plastic materials to make them stronger. 3D carbon fiber printing could replace the slower carbon-fiber layup process. Buyers have the advantage to reduce the number of steps required in electromechanical device assembly by introducing conductive carbomorph.

4. Graphene

Graphene has picked up popularity in the choices used in 3D printing because of its conductivity and strength. It is widely used to produce component parts with flexibility, for instance, touchscreens, solar panels, and building parts. Graphene is light and strong, so it is a suitable material to make a broad range of products.

5. Paper

Paper materials in 3D printing technology achieve more realistic prototypes than flat illustrations. Buyers can convey the actual essence of the design with greater accuracy and detail.

6. Powders

Powder materials are used in the most state-of-the-art 3D printing processes. The powder is melted inside the printer and distributed in layers to achieve the desired level of texture, thickness, and patterns.

The most common sources of powder materials include:

– Polyamide (Nylon): It is strong and highly flexible, so it can be used for high levels of detail on 3D-printed products. It is usually used for joining pieces and interlocking parts. Nylon makes everything from fasteners and handles to toys and figures.

– Alumide: It is a mixture of gray aluminum, polyamide, and alumide powder. The combination produces strong 3D-printed models and products. It can be recognized by its grainy and sandy appearance and is reliable for industrial prototypes and models.

7. Resins

Resins are limitedly used in 3D printing. This is because they offer limited flexibility and strength. Resin is made of liquid polymer and reaches its end state with exposure to UV light. It is available in various colors, including white, black, orange, blue, red, green, and transparent.

This material comes in three categories:

– High-detail resin: It is usually used for small models that need intricate detail.

– Transparent resin: It has an aesthetic appeal that is applied on smooth-surface 3D prints.

– Paintable resin: It is the strongest class of resin and is suited for a wider range of 3D-printed products. The items have a smoother texture and are transparent in appearance.

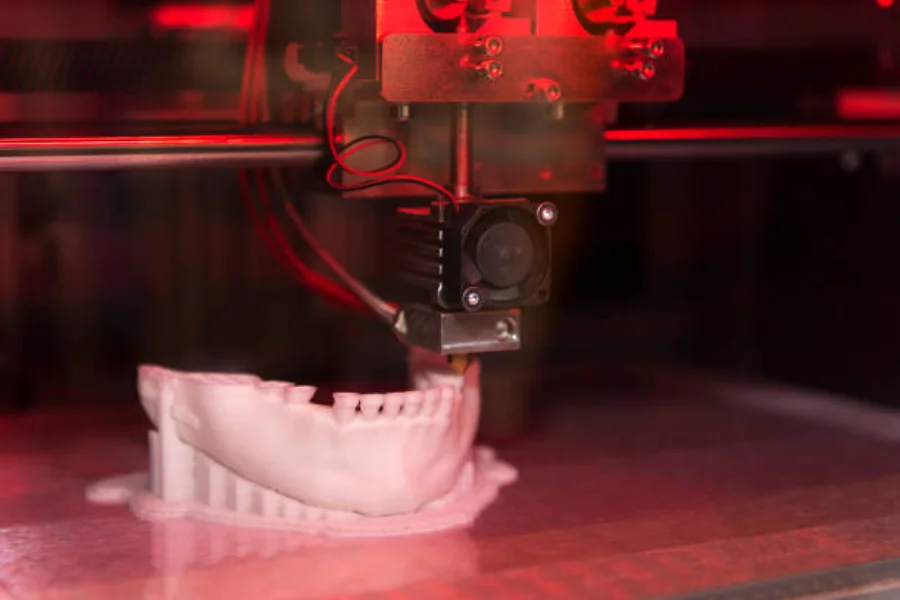

8. Nitinol

Made from a combination of nickel and titanium, nitinol is commonly used in medical implants due to its super-elasticity. This material can be bent to considerable degrees without breaking and can easily restore its original shape. As a result, nitinol is one of the strongest materials with outstanding elastic properties.

Conclusion

Buyers can now determine the texture, shape, and strength of 3D-printed products with unprecedented flexibility. 3D printing achieves the desired quality in production through simpler and fewer steps than other manufacturing methods. The guide above shows buyers the materials suitable for usage in the printing process. If you are looking to purchase 3D printers, click here to learn what to look for when selecting a 3D printer. The choice mainly depends on the production goals and budget available. To find high-performance 3D printing materials, visit Alibaba.com.