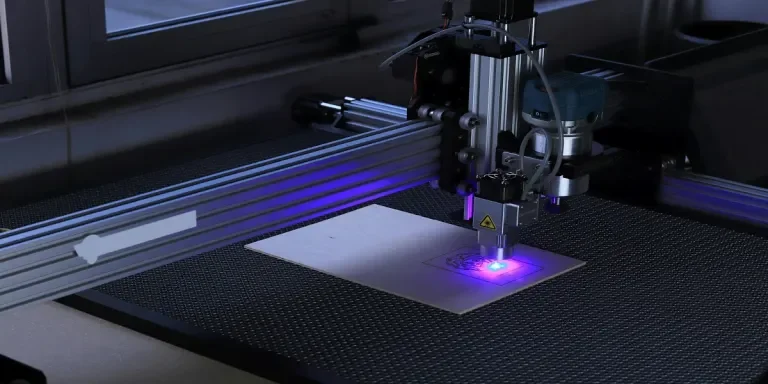

Laser cutting technology works by directing a high-power laser to vaporize material and create a cut edge. There are several different types of laser cutters, but basically a laser cutting machine is any type of machine that uses a laser to cut or engrave the desired material.

Laser cutters are increasingly popular for their speed and accuracy compared to more mechanical cutting methods. But with all the different models available on the market today, it might be hard to know which laser cutter to buy and which machine is right for you. To help you choose the best model, this article will offer a comprehensive guide to sourcing the right laser cutting machine.

Table of Contents

The projected growth of the laser cutting market

What to consider when selecting a laser cutter

Further buying considerations

Target markets for laser cutting machines

Final thoughts on which laser cutter to buy

The projected growth of the laser cutting market

In 2015, the global laser cutting machine market was valued at USD 3.02 billion in 2015 and grew at a healthy compound annual growth rate (CAGR) of 9.3% to a global value of $5.7 billion by 2022. CO₂ lasers drove this growth due to the increased demand for improved machining equipment in automotive and consumer electronics.

Despite the impact of the COVID-19 pandemic, the global market for laser cutting machines remains strong, and is projected to reach US$7.3 billion by 2027, growing at a CAGR of 8% between 2020-2027.

However, the fiber laser segment is projected to exceed that growth at a CAGR of 9.2%, reaching a value of US$2 billion by 2027, while growth in the CO₂ lasers segment has been revised down to 8.3% CAGR for the same period. So although the CO₂ laser market continues to grow well, fiber lasers are beginning to dominate the market over the coming period.

What to consider when selecting a laser cutter

An overview of laser cutting technology

Laser cutters use a high powered optical laser, directed onto a cutting surface. The narrowly focused laser heat melts, vaporizes or ablates the cutting surface and the residue is blown away to leave the cut or engraving.

Organic materials like card, leather and wood burn and absorb light easily, and can be cut easily with low power lasers. However, metal is reflective and heat conductive, so a metal laser cutter is required as it has a more powerful laser.

There are three main types of laser cutting machines, with each type more suitable to specific materials and applications. These are CO₂ (gas) lasers, crystal (Nd:YAG) lasers, and fiber lasers. This section will explain the different technologies, and their respective advantages and disadvantages, in more detail.

CO₂ (gas) laser cutters

These are the most common lasers, being the first laser cutting machines to market over 20 years ago. They are suitable for cutting and engraving glass, plastics and foams, leather, wood, paper/card and acrylic.

CO₂ laser cutting machines use CO₂ gas, along with other gasses like helium and nitrogen. The electrically-stimulated gas mixture produces the laser beam. The laser reflects off mirrors within the laser cutter before being focused and directed by a lens onto the working surface.

Entry level CO₂ laser cutters are usually found in the 30w to 150w power range, which is sufficient for most leather and wood cutting and engraving. Higher power versions for cutting metal can be in the 1000-3000w range.

Advantages of CO₂ laser cutter

- good for cutting organics such as wood, leather, card and rubber

- low power lasers around 30-150w are adequate for most organics

- CO₂ lasers leave a sharp cut edge on metals or specialized materials

- low upfront investment cost

Disadvantages of CO₂ laser cutter

- not suitable for highly reflective metals as they cannot cope with the laser being reflected back into the laser emitter

- take twice as long to cut than fiber cutters

- sensitive and fragile due to the internal mirrors and glass tubing

- need periodic realigning function at their best

- Require regular maintenance and servicing

Crystal (Nd:YAG) laser cutters

Crystal laser cutting machines have specific applications where high power and high intensity focus is needed. Applications are typically for heavy industrial cutting of plastics, metals and ceramics. They now tend to be more common as the machines of choice for the beauty industry for hair and blemish removal.

Crystal laser cutting machines use neodymium (Nd) and neodymium yttrium-aluminum-garnet (Nd:YAG) to generate the laser beam. Nd lasers are typically used where high energy, low repetition is required. Nd:YAG lasers are used where very high power is needed.

Nd:YAG lasers are used in manufacturing and automotive for cutting and welding steel, semiconductors and various alloys. In these cases the power ranges are typically in the 1000–5000w range.

Advantages of Nd:YAG laser

- these lasers have a high intensity, so are more suitable for cutting through stronger, thicker materials

- suitable for heavy industry metal cutting

- cheap upfront cost for the laser machine

Disadvantages of Nd:YAG laser

- high operating cost due to power consumption

- the higher power leads to quicker parts degradation and replacement, and costly maintenance

Fiber laser cutters

Fiber laser cutting machines first came to market around 2008 and have demonstrated benefits over CO₂ lasers. Applications include metals, organic materials, and plastics.

Fiber laser cutting machines are solid-state lasers that use a seed laser, amplified and magnified using optical fiber. They are more efficient than CO₂ and crystal lasers, and the absence of moving parts reduces the need for maintenance.

The power range starts at around 20-30w for desktop applications such as jewelry or fabric engraving and cutting, and goes up to 4000w and beyond for metal cutting standing machines, and even higher for large scale industrial machines.

Fiber laser advantages

- fiber lasers are 4-5 times faster than Nd:YAG lasers, and 2 times faster than CO₂ lasers with the same power

- around 30% more efficient use of laser energy, and 20-30% consumption compared to CO₂ lasers

- for reflective materials, fiber lasers work better than CO₂ lasers

- fixed parts (solid state) require less maintenance than CO₂ lasers.

Fiber laser disadvantages

- fiber lasers tend to come at a higher price than CO₂ lasers

Further buying considerations

Machine type: for most users the choice is between CO₂ and fiber lasers. Fiber lasers have a higher initial cost, but ongoing maintenance is low.

Materials: CO₂ lasers are the usual choice for organics, and for metals where a cleaner cut edge is required. Fiber lasers are more efficient at thicker and reflective metals. For very thick metal cutting Nd:YAG lasers may be a better choice.

Power: typically a higher power means a faster and more reliable cut. All lasers are available in higher powers, but fiber lasers are more efficient.

Bed Size: the size of the cutting bed determines the size of material. Desktop cutters can have a bed size as small as 300mm x 300mm, while large industrial machines can be upwards of 6000mm x 3000mm.

Support: CO₂ and Nd:YAG lasers have more wear than fiber lasers, and are likely to need more ongoing maintenance and optical adjustment.

Target markets for laser cutting machines

China, Japan, and South Korea will dominate the CO₂ laser market growth due to demand for high precision laser cutting machines across the electronics, semiconductors and manufacturing industries. Europe’s CO₂ laser market is projected to grow at a steady pace due to the maturity of the market. North America is expected to show similar growth.

China is also expected to show high growth in the fiber laser market, due to demand for high power cutting solutions in fabricated metal products. Europe, and especially Germany, is predicted to show high growth in the fiber laser market from their semiconductor and integrated circuit industry. In the U.S. the automotive and consumer electronics industries remain strong and will fuel a healthy market for fiber lasers.

Final thoughts on which laser cutter to buy

There is an increasing demand for precision laser cutting and engraving equipment across a range of industries. Entry level low-cost desktop laser cutting machines are widely available and are the machines of choice for wood, leather and plastics cutting and engraving. Large size high-power lasers are also readily available for cutting sheet metal and machine parts.

Each technology has its merits and applications, and there is a wide choice of machines available. We hope that this guide has helped you in deciding which laser cutter to buy. Check out Alibaba.com to learn more and explore the most popular machines available on the market today.