An engine is sufficient to power a vehicle at incredible speeds. However, some petrolheads always want more thrill, speed, and adrenaline as they cruise roads at breakneck speeds. Turbochargers were made for these specific groups of people. From how to repair and maintain a turbocharger to replacing one, this article will offer the assistance needed when handling turbochargers.

Table of Contents

Purpose of a turbocharger

Failure causes in turbochargers

How to maintain a turbocharger?

How to replace a turbocharger?

Original or aftermarket: a cost-effective way to choose the right turbocharger

Purpose of a turbocharger

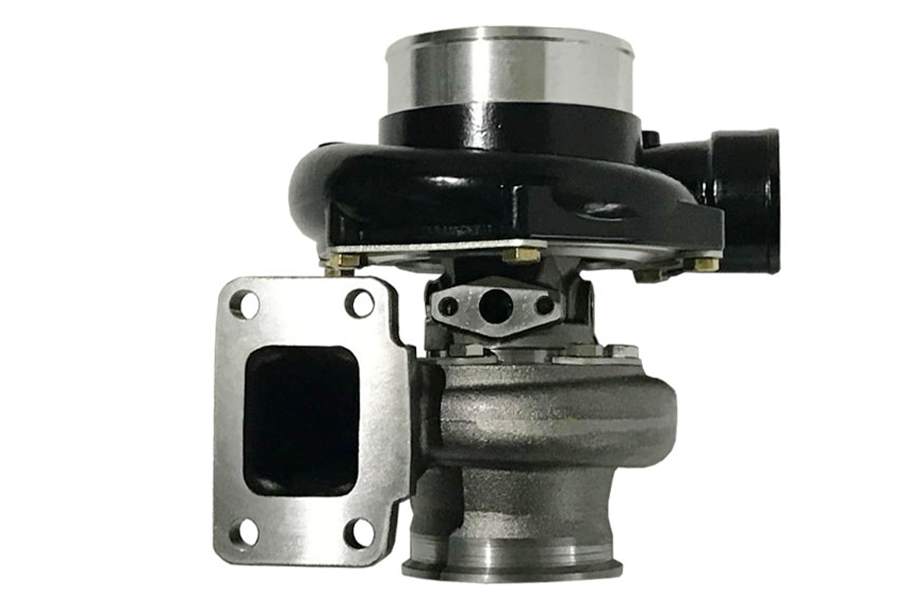

The primary work is to combust fuel to provide energy used to move a vehicle. A turbocharger enables an engine to burn more fuel by adding compressed air. Compressed air molecules are packed closer to each other when a turbocharger is used instead of a regular engine.

Failure causes in turbochargers

There are three main reasons for turbocharger failure:

Oil starvation

Oil starvation happens when there is hard acceleration right after a cold start. It does not give oil enough time to circulate in the engine and the turbo, resulting in the wearing down of the bearings.

Oil contamination

Oil can be contaminated with fine carbon particles emitted during combustion. A massive build-up of these particles results in abrasive damage to the turbo, the moving parts, and the bearings.

Foreign object damage

They may originate from broken pieces from a previously failed turbocharger from objects sucked in through the air inlet, which results in loss of performance of the turbo, pitting on the compressor blades, and chipping of the compressor or turbine.

Overspeed and excessive temperature

Overworking a turbocharger by pushing it beyond its designed limit will contribute to its failure. This is in addition to poorly maintaining it or performing unauthorized upgrades on the engine.

Lack of lubrication

Lack of lubrication will lead to metal friction, high temperature, and turbo fatigue cracking.

How to maintain a turbocharger?

While a turbocharger should provide the speed it’s touted to offer, its maintenance is essential.

Treat boost gauges cautiously

The boost gauges indicate air pressure and boost pressure in the combustion engine. This directly affects the vehicle’s power, improving its performance. These gauges help the driver maintain an optimal acceleration because excessive acceleration stresses the turbo, reducing its lifetime.

Switch to a lower gear

Switching to a lower gear means reducing the number of times required to maximize boost pressure.

Warm up the car before driving

Warming up the car before driving allows the lubricants to thin and circulate freely in every part of the engine.

Allow the car to cool after driving

Allowing the vehicle to cool down for a few minutes will allow the turbo time to cool and prevent wear and tear.

Ensure regular oil maintenance

High-quality synthetic oil is recommended because it can handle the heat and pressure generated by the turbo. This is in addition to having an oil change every 5000 miles.

How to replace a turbocharger?

Below is a list of the steps to be taken when disassembling a turbocharger:

- Inspect the turbo for any breakage.

- Drain off the old oil.

- Clean the engine with chemicals.

- Disassemble the air and oil filters.

- Dismantle their ducts and clean them thoroughly. Inspect the nozzles for damage.

- Dismantle the oil pipeline. Inspect for any damaged tubes and replace them.

- Ensure that the intercooler is thoroughly cleaned, inspected for damage, and replaced if necessary.

- Dissemble the turbocharger

- Inspect cracks on the flange of the exhaust system and clean it thoroughly.

Assembly of the new turbocharger:

- Ensure all objects of the turbocharger are present.

- Install the oil filter. Fill it with oil.

- Install the intercooler and connect all the nozzles well.

- Install the new turbocharger.

- Ensure the gasket is firmly fastened. Also, install the oil pipeline and oil the turbocharger.

- Then connect the turbine be with the oil pipe.

- Install the air filter and connect all the air ducts.

- Ensure all the remaining nozzles are tightly fastened in their place.

- Inspect the turbocharger for any leaks.

- Fill the engine with oil.

- Start the engine and search and eliminate any oil leakage and exhaust gases.

- Inspect for turbine operation mishaps by test driving.

Original or aftermarket: a cost-effective way to choose the right turbocharger?

Original equipment manufacturers, otherwise known as OEMs, are made by branded manufacturers. OEMs are usually original components made for their manufacturer’s vehicles. They’re accessed directly through the manufacturer’s dealers. Also, they guarantee quality and are always more costly. A good example is Upgrade GTX3582R GEN2 GT35 Ball Bearing Turbocharger.

On the other hand, aftermarket parts are manufactured by different manufacturers who specialize in vehicle parts and not vehicles. Aftermarket manufacturers provide a wide range of products to rival OEMs. Their products may have more features than OEMs at lower prices. An excellent example is the 6CT8.3 diesel engine turbocharger and Raiko Aftermarket K0CG 5303-970-0469 Turbocharger.

Conclusion

Turbochargers can bring a massive difference to the performance of a car. However, as we’ve seen, they’re to be maintained well; otherwise, they’ll malfunction and have a short lifespan. This article also gave an outline on disassembling and assembling a turbocharger. The availability of OEMs and aftermarket turbochargers has also been covered together with tips that a driver should use to maintain their turbocharger.