A conventional UV DTF printer can never bypass the manual laminating process. In contrast, the Procolored UV DTF-i608 2-in-1 printer incorporates a laminator to automate the laminating process, so customers can say goodbye to manual lamination and focus more on printing.

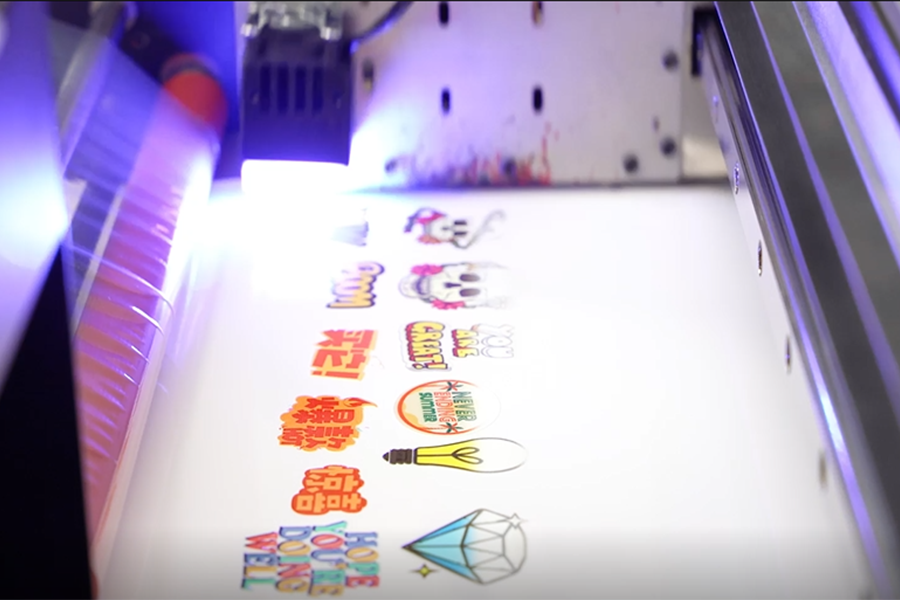

Compared to the previous generation UV DTF printer, the print width of the new UV DTF printer has been increased by about 30mm, so more patterns can be printed on the same film. In addition, the combination of dual printheads and auto-laminating functions will eventually bring production efficiency to a new level. The UV DTF-i608 laminating printer applies patented white ink automatic circulation and automatic cleaning to prevent nozzles from clogging.

The UV varnishing function is another highlight of the UV DTF-i608 printer compared to a common DTF printer. The UV varnishing technology coats the printed pattern with a reflective outer layer that looks more luxurious and special.

The Procolored UV DTF-i608 printer is the ideal choice for customers who want to output high-end patterns and print on uneven, hard surfaces and surfaces with a certain drop degree. The UV DFT laminating printer overcomes the problem that a UV printer is not able to solve. UV printers have pushed the limits of traditional printers by printing directly on the substrate surfaces of almost all materials. However, printing with a UV printer on surfaces with a 2-10mm drop (depending on the size and performance of a UV printer) may result in distorted printing. To address this problem, the Procolored UV DTF sticker printer combines UV printing and DTF printing technologies to meet the changing needs of the market. The UV DTF-i608 printer prints on the film first and then transfers the patterns to the substrate. This clever idea makes it possible for the Procolored UV DTF-i608 printer to transfer patterns to all kinds of surfaces and shapes like plastic, metal, wood, glass and so on.

Table of Contents

UV DTF printer and laminator in one machine

Dual printheads array

UV varnishing & golden foil transfer

Automatic cleaning & white ink automatic circulation

Specs of Procolored 2-in-1 UV DTF-i608 printer

UV DTF printer and laminator in one machine

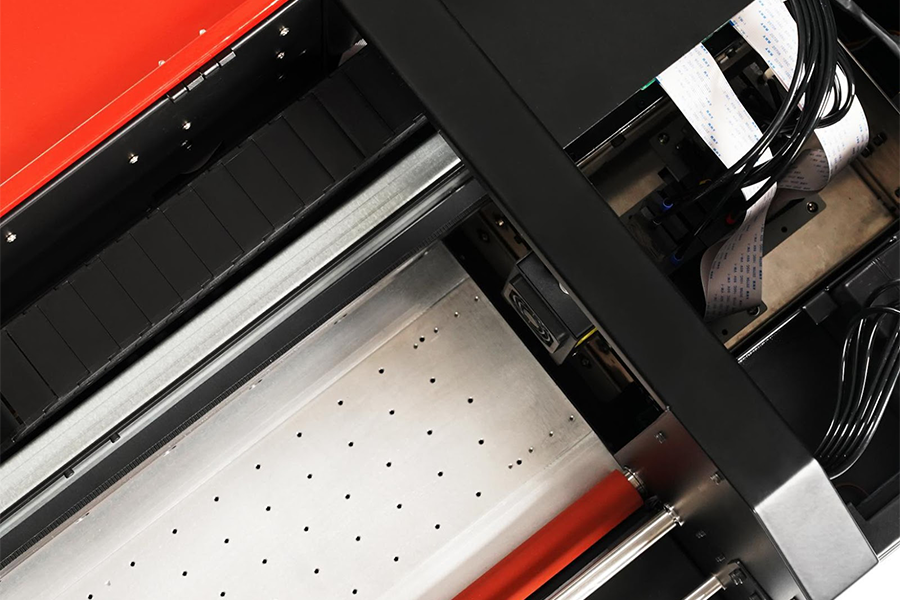

The last generation UV DTF printer usually takes up significant space. To complete the UV DTF printing process, it is necessary to place a laminator in the workshop, which will occupy even more space. Given this customer pain point, the innovative R&D engineers have integrated the laminator into the UV DTF printer. And finally, the Procolored 2-in-1 UV DTF printer was launched to complete automatic printing and laminating at the same time. With this advanced technology, printing efficiency is increased by about 25%. Additionally, the new UV DTF-i608 laminating printer applies a roll feeder to skip the process of adding films manually and further improve production efficiency.

Dual printheads array

Increasing the number of printheads is not just to improve work efficiency, but also to enhance printing accuracy and color vibrancy. A printhead contains a number of nozzles, and the number of nozzles determines the printing speed and quality. With dual printheads installed in the Procolored UV DTF-i608 printer, the printing speed is much faster than that of single head UV DTF printers under the same conditions.

UV varnishing & golden foil transfer

Generally, the printer will first print out a special glue to ensure the film can be laminated successfully; next, the white ink and color ink are printed sequentially. The varnish is printed at the last step, which endows the outer layer of the pattern with a reflective look. Patterns printed with varnish will glow at certain angles, which differentiates UV varnish printing from ordinary UV printing.

UV DTF golden foil transfer is another eye-catching printing technology that the printer applies. Hot stamping can create golden gloss patterns with a sophisticated and luxurious look that can capture people’s hearts.

These technologies not only upgrade the visual feeling of the printed patterns but also endow them with a special sense of touch.

Automatic cleaning & white ink automatic circulation

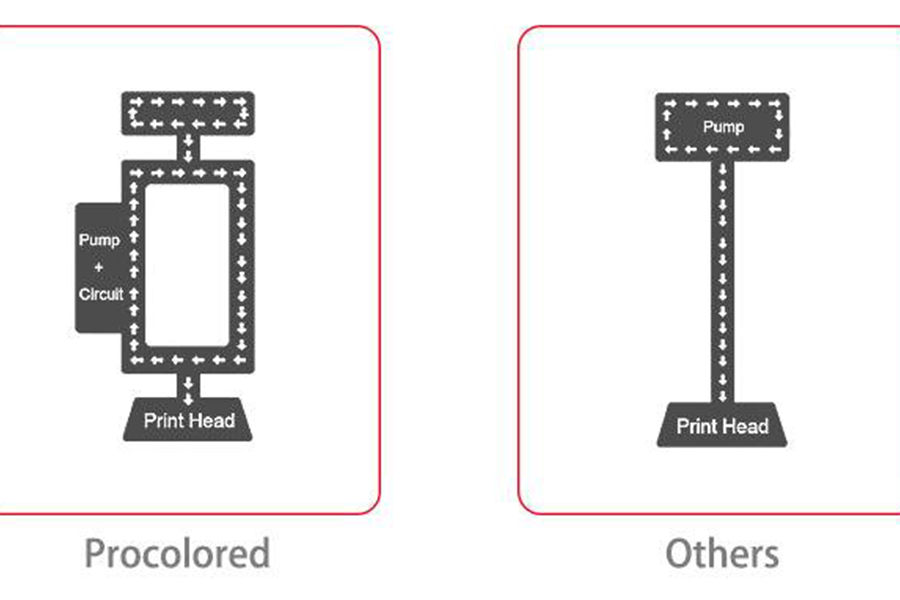

To prevent nozzles from clogging, the Procolored UV DTF printer is equipped with a cleaning unit that works automatically according to the set interval to ensure the printheads are in good working condition. The unique technology of white ink automatic circulation offers a pump and ink circuit solution to make sure the white ink is in continuous circulation. This white ink circulation method is more advanced than the traditional method, which can not provide a circuit for white ink. The combination of these two technologies minimizes printhead clogging and offers a 50% longer service life for printheads.

Printing with the Procolored UV DTF-i608 printer saves time and money thanks to its integration with a laminator and the use of dual printheads array and continuous roll printing. The UV varnish printing function creates an attractive and fascinating pattern with a glossy look and vivid tactile impression. With these advanced technologies, printhead clogging can be minimized to prolong the printhead’s lifetime and improve the printing experience.

Specs of Procolored 2-in-1 UV DTF-i608 printer

| Model | UV DTF-i608 | Print Head | 2*Epson printheads |

| Printing Accuracy | 8PASS, 12PASS, 16PASS | Print Width | 330mm, unlimited length |

| Print Speed | 8PASS; 2m2/H | Optional Software | Ultraprint(Free), RIPrint(Charged) |

| Print Height | 2mm (unadjustable) | OS | Windows |

| Ink Consumption | 1m2/20ml | Color Scheme | CMYKCM+WWOS |

| Ink Supply Method | Continuous ink supply | Glue Printing | Supported |

| Ink Output | Supports white, color, varnish, glue printing at the same time | Varnish Printing | Supported |

| UV Lamp Service Life | 1 year | Package Size | L1070*W520*H500 |

| UV Lamp Cooling System | Air cooling | Printer Size | L1000*W450*H390 |

| UV Lamp Power | 40-160W | Net Weight/Gross Weight | 53KG/65KG |

| Motor Drive | Pulse servo motor drive | Outer Packaging | Export wooden box (with forklift feet) + foam |

| Voltage/Plug | AC100~230V/according to the country (optional) | ||

| Print Media | Film, release paper | ||

| Transfer Media | Plastic, stone, metal, glass, ceramic, wood, wall and so on, with unlimited shape. | ||

| Warranty | 3-year warranty [Parts in contact with ink (or parts damaged by ink) are not guaranteed.] |

Shenzhen Xinyu Automation Technology Co., Ltd. (brand: Procolored) was founded in 2005, with an 1800-square-meter factory, and has been exploring the inkjet printer field for more than 16 years, especially UV/DTG/UV DTF/DTF printers. With 6 overseas warehouses, the company has served over 8,000 clients from all over the world. Moreover, the company has more than 30 professional engineers with powerful R&D capabilities.

Disclaimer:The information set forth above is provided by Procolored independently of Alibaba.com. Alibaba.com makes no representation and warranties as to the quality and reliability of the seller and products.